Troubleshooting, Please read the following carefully – Harbor Freight Tools 97719 User Manual

Page 14

Page 14

SKU 97719

For technical questions, please call 1-800-444-3353.

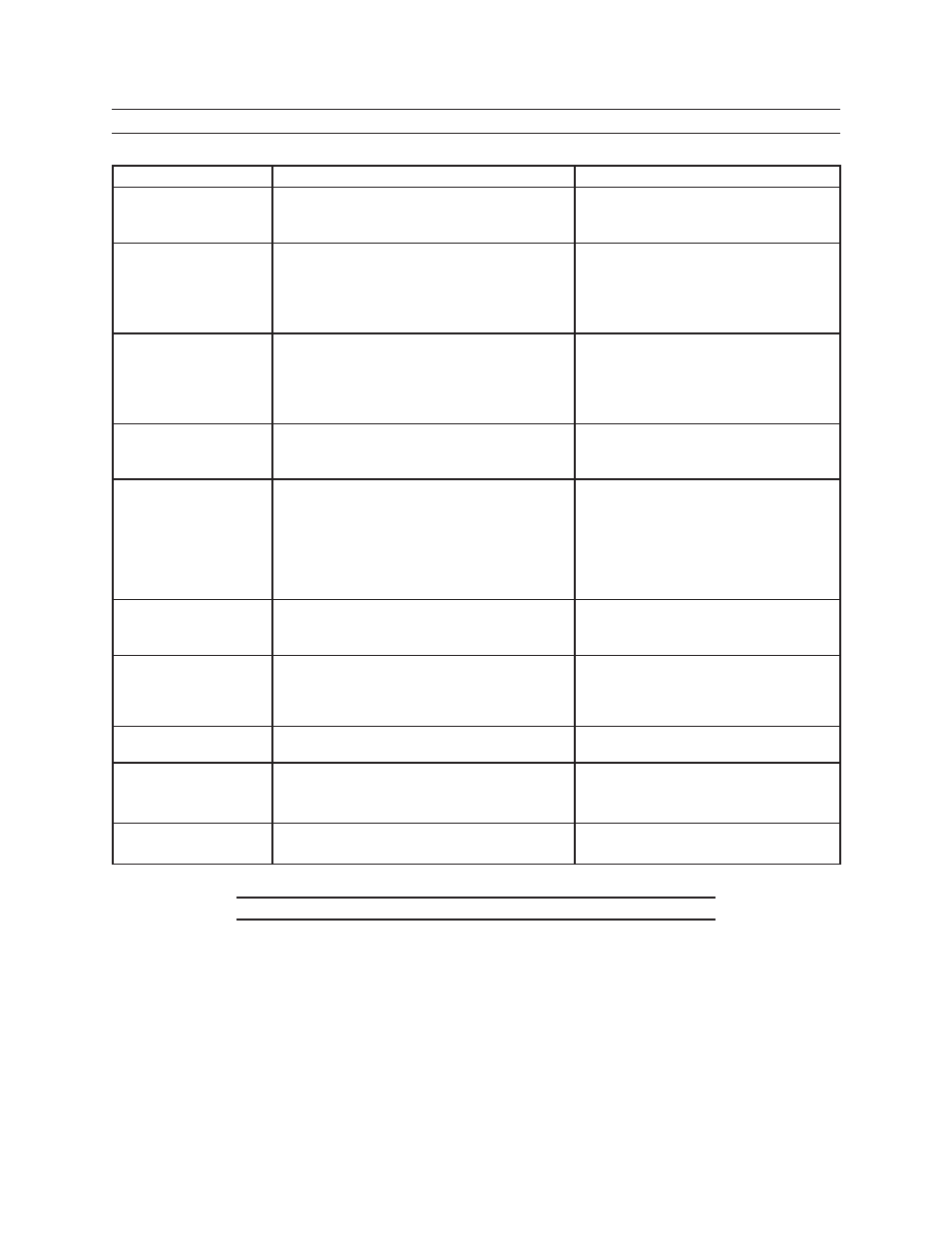

problem

possible Causes

possible Solutions

Welder does not “hum”

when turned on.

No power at electrical outlet.

1.

Broken or damaged Power Cord.

2.

Check circuit fuse or circuit breaker.

1.

Have Power Cord repaired or replaced by

2.

a qualified electrician.

Welder “hums” but does

not weld.

Inadequate current at electrode and/or poor

1.

connections at Welder.

Check Ground Clamp, Cable, and

1.

connection to workpiece.

Check Welding Cable and Electrode

2.

Holder.

Check all Welder external connections.

3.

Arc difficult to strike.

Electrode diameter too large.

1.

Workpiece not properly grounded.

2.

Heavy loads, making power line voltage low.

3.

Use smaller diameter electrode.

1.

Verify proper grounding (no paint, varnish,

2.

or corrosion).

Run Arc Welder on dedicated 230 volt

3.

circuit.

Welder gives trickle shots.

Accidental contact with workpiece.

1.

Current leakage caused by moist clothing or

2.

work area.

Avoid contact with workpiece.

1.

Make sure clothing and work area are dry.

2.

Welder overheats, blows

fuses, trips circuit breaker.

Use of extension cord.

1.

Electrode diameter too large.

2.

Overloaded circuit.

3.

Relocate Arc Welder to avoid use of

1.

extension cord. If relocation of Welder

is not possible, use thicker (lower gauge

number) extension cord.

Use smaller diameter electrode.

2.

Run Arc Welder on dedicated 230 volt

3.

circuit.

Bead is intermittently too

thin or too thick.

Inconsistent travel speed.

1.

Output Amp setting too low.

2.

Decrease and maintain travel speed.

1.

Increase output Amp setting or change to

2.

smaller diameter electrode.

Electrode sticks to work-

piece.

Arc length too short.

1.

Output Amp setting too low.

2.

Lift electrode to correct arc length as soon

1.

as arc is struck.

Increase output Amp setting or change to

2.

smaller diameter electrode.

Electrodes sputter and

stick.

Damp electrodes.

1.

Use dry electrodes and store in a dry

1.

location.

Weld bead does not pen-

etrate base metal.

Travel speed too fast.

1.

Arc length too short.

2.

Output Amp setting too high.

3.

Decrease travel speed.

1.

Increase arc length.

2.

Reduce output Amp setting.

3.

Ragged depressions at

edge of weld.

Slow and/or inconsistent travel speed.

1.

Output Amp setting too high.

2.

Increase and maintain travel speed.

1.

Reduce output Amp setting.

2.

tROubLEShOOting

pLEASE READ thE FOLLOWing CAREFuLLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR ExPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE

UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER

ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION

OF REPLACEMENT PARTS THERETO.