Dvanced, Atalyst, Ystem – HONDA Insight User Manual

Page 89: Lean nox catalyst functioning

89

A

DVANCED

C

ATALYST

S

YSTEM

The insight is designed to operate at a very lean air fuel ratio during light throttle cruise conditions. The

mixture can be as lean as 22:1 if conditions allow. This provides very good fuel economy, and low HC and

CO emissions. However, the lean mixture also causes a rise in combustion temperature, and high NOx

production is the result.

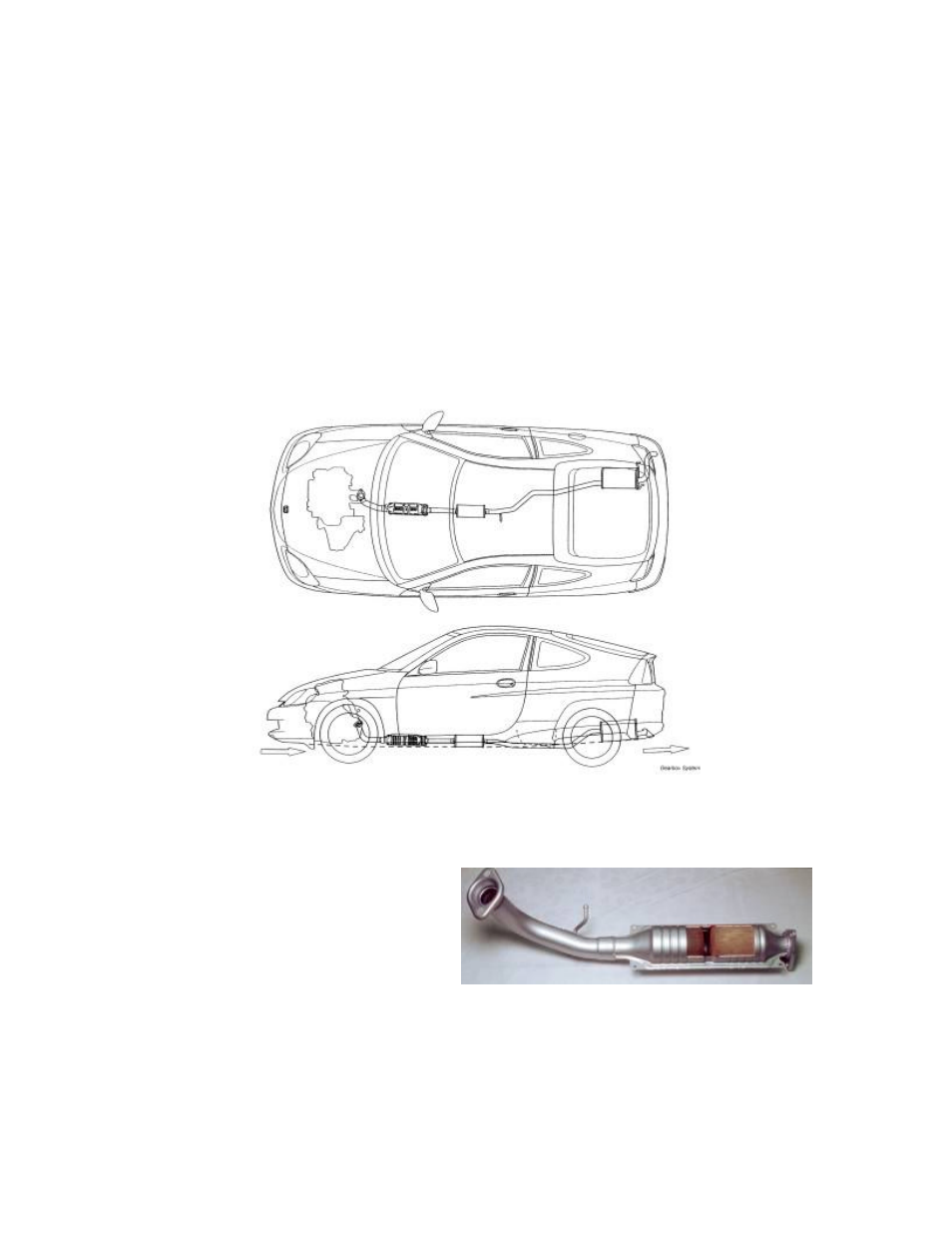

In order to prevent high NOx tailpipe emissions during lean burn operation, the Insight uses a dual

catalyst system that includes an extra NOx storage/NOx reduction catalyst.

The 3-way catalyst is closely coupled to the exhaust manifold to minimize heat-up time, thus reducing

emissions after a cold start.

The lean NOx catalyst is in the conventional location, underneath the car.

Lean NOx Catalyst Functioning

The lean NOx catalytic converter is

comprised of a ceramic A1203 substrate, a

platinum (Pt) catalyzing surface, and a titanium-

sodium (Ti-Na) NOx storage surface.

During lean burn operation, the exhaust gas

contains a larger percentage of oxygen (O2) and

NOx, the NOx being primarily nitrogen

monoxide (NO). The platinum catalyzes the O2

and NO to produce nitrogen dioxide (NO2), which is able to be stored on the Ti-Na surface.

When it determines that the Ti-Na surface is saturated, the Insight temporarily richens the mixture. This

action decreases the NOx and O2 in the exhaust, and raises the levels of hydrocarbons (HC) and carbon

monoxide (CO). The platinum is then able to use the HC and CO to catalyze the NO2 (that has been stored)

into harmless nitrogen gas (N2), carbon dioxide (CO2) and water vapor (H20).