Communications, Wiring details – Honeywell EXCEL 10 W7751H User Manual

Page 7

EXCEL 10 W7751H SMART VAV ACTUATOR

7

95-7553—04

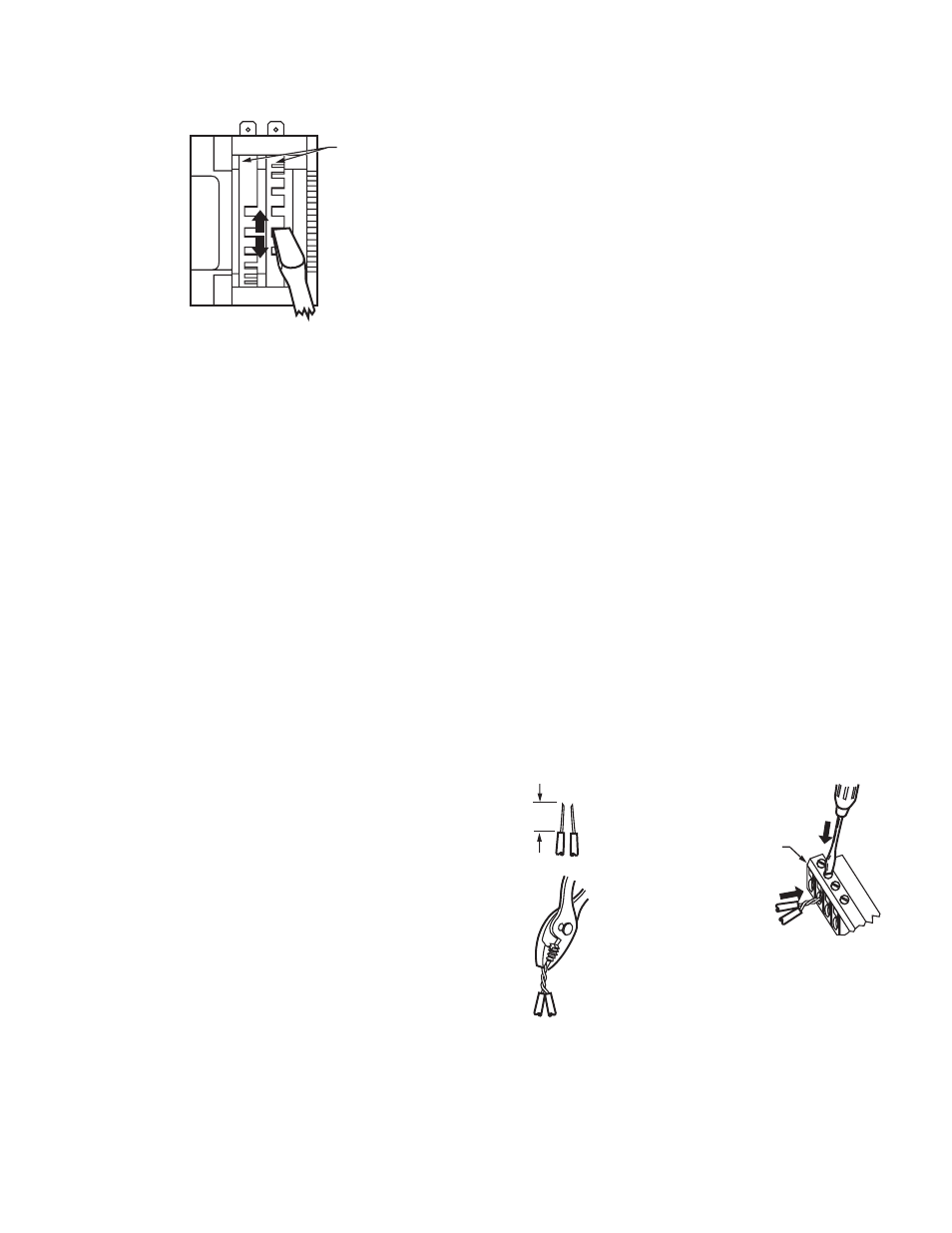

Fig. 14. Auxiliary switch cam adjustment.

NOTE: For 2 or 3 switch models, cams align with their

respective switches and are individually set

using the same procedure described above.

6. Ensure switch activation at the desired degree of stroke

by commanding the actuator to both fully open and fully

closed; see step 3.

NOTE: Switches can also be preset prior to actuator

installation if angular switch position is known.

Communications

Refer to L

ON

W

ORKS

® Bus Wiring Guidelines, form 74-8565,

for complete description of L

ON

W

ORKS

® Bus network topology

rules.f

If a longer L

ON

W

ORKS

® Bus network is required, a Q7740A

2-way or Q7740B 4-way Repeater can be added to extend

L

ON

W

ORKS

® Bus length, only if this is an Energy

Management (PAZX) Bus.

IMPORTANT

The Q7740A,B Repeaters cannot be used in

smoke control applications.

A Q7751A Router can only be added to an Energy

Management Bus to partition system into two segments

(effectively doubling L

ON

W

ORKS

® Bus length). Only one

router is allowed with each Excel 10 Zone Manager (or Excel

15 Building Manager), and each network segment can have a

maximum of one repeater.

Pull the cable to each device on the L

ON

W

ORKS

® Bus and

connect to communication terminals 11 and 12 (W7751H).

IMPORTANT

Screw type terminal blocks are designed to accept

no more than one 14 AWG (2.0 mm

2

) conductor.

Multiple 14 AWG (2.0 mm

2

) wires can be connected

with a wire nut. Include a pigtail with this wire group

and attach the pigtail to the individual terminal block.

Notes on LonWorks® Bus Communications Wiring:

• All field wiring must conform to local codes and ordinances

(or as specified on the installation drawings).

• Approved cable type is Level IV 22 AWG (0.34 mm

2

)

plenum or non-plenum rated unshielded, twisted pair, solid

conductor wire:

— For nonplenum areas, use CMP listed cable.

— In plenum areas, use CMP listed cable.

• Do not bundle output wires with sensor, digital input or

L

ON

W

ORKS

® Bus wires.

• Ensure that neither L

ON

W

ORKS

® Bus wire is grounded.

• In noisy (high EMI) environments, avoid wire runs parallel

to noisy power cables, motor control centers, or lines

containing lighting dimmer switches. Keep at least 3 in.

(76 mm) of separation between noisy lines and

L

ON

W

ORKS

® Bus cable.

• Do not use different wire types or gauges on the same

L

ON

W

ORKS

® Bus segment:

— Step changes in line impedance characteristics cause

unpredictable reflections on the L

ON

W

ORKS

® Bus.

Wiring Details

Wire to the terminal blocks as follows:

1. Strip 3/16 in. (5 mm) insulation from the conductor.

2. Insert the wire in the required terminal location and

tighten the screw to complete the termination.

NOTE: With the exception of 14 AWG (2.0 mm

2

), if

inserting two or more wires into one terminal

location, twist wires together before inserting

them. See Fig. 15. Deviation from this rule can

result in improper electrical contact.

The controller on the W7751H has the terminal arrangement

shown in Fig. 16. Fig. 16 through 21 provide detailed wiring

diagrams for the W7751H. Refer to installation diagrams for

specific wiring.

NOTE: Ensure Configuration DIP Switch is set as shown in

Fig. 19. Switches 1 through 3 set ML7984B Valve

Actuator timing to match W7751H outputs (0.1 sec.

minimum with maximum time of 25.6 sec.). Switch 4

determines actuator action (Off = Direct Acting, On =

Reverse Acting).

Fig. 15. Attaching two or more wires at terminal blocks.

SWITCH CAMS

M2076A

1/2

(13)

STRIP 1/2 IN.

(13 MM) FROM

WIRES TO BE

ATTACHED AT

ONE TERMINAL.

1.

2.

TWIST WIRES

TOGETHER

WITH PLIERS

(A MINIMUM OF

THREE TURNS).

3.

CUT TWISTED END OF WIRES TO

3/16 IN. (5 MM) BEFORE INSERTING

INTO TERMINAL AND TIGHTENING

SCREW. THEN PULL ON EACH WIRE

IN ALL TERMINALS TO CHECK FOR

GOOD MECHANICAL CONNECTION.

M11413

CONTROLLER OR

WALL MODULE

E-BUS CONNECTOR

TERMINALS