Symbols and specific safety instructions – Harbor Freight Tools 66902 User Manual

Page 5

SKU 66902

for technical questions, please call 1-800-444-3353.

Page 5

sYMBOls and

specific safetY

instructiOns

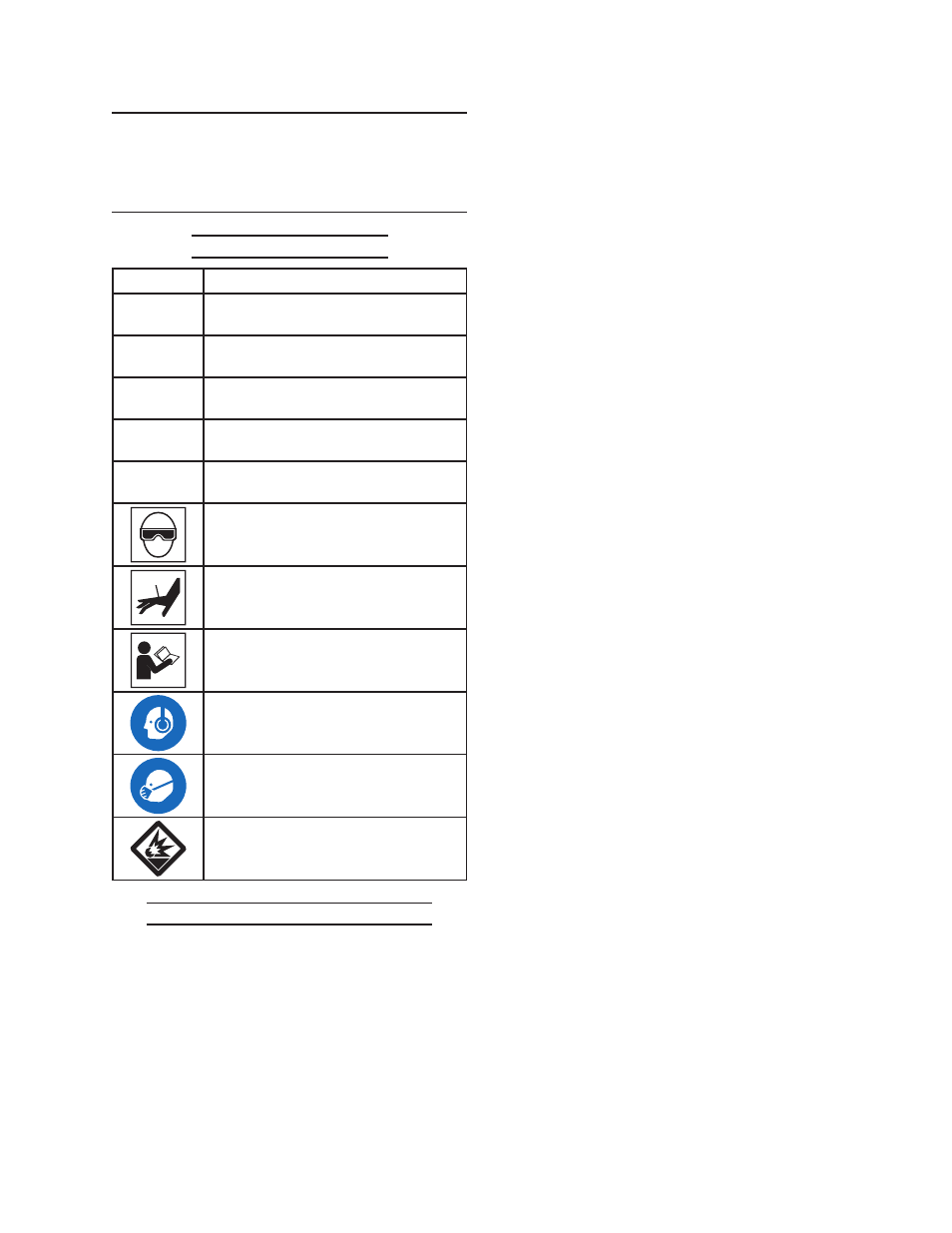

Symbol Definitions

symbol

property or statement

psi

Pounds per square inch of pressure

cfM

Cubic Feet per Minute flow

scfM

Cubic Feet per Minute flow at

standard conditions

npt

National pipe thread, tapered

nps

National pipe thread, straight

WARNING marking concerning Risk

of Eye Injury. Wear ANSI-approved

eye protection.

Warning marking concerning Risk of

Puncture Injury. Wear heavy-duty

work gloves.

Read the manual before set-up and/

or use.

WARNING marking concerning Risk

of Hearing Loss. Wear hearing

protection.

WARNING marking concerning Risk

of Respiratory Injury. Wear NIOSH-

approved dust mask/respirator.

WARNING marking concerning Risk

of Explosion.

Specific Safety Instructions

Operators and others in work area

1.

Must wear ansi-approved safety

goggles with side shields during

use. The employer is responsible to

enforce use of eye protection by the

operator and others in the work area.

Keep fingers away from Trigger

2.

when not driving fasteners to

avoid accidental firing.

Always assume the tool contains

3.

fasteners.

Do not point the tool toward yourself

4.

or anyone whether it contains fasten-

ers or not.

Do not actuate the tool unless the

5.

tool is placed firmly against the work-

piece.

Respect tool as a working implement.

6.

No horseplay. This tool is not a toy

7.

and can be deadly if misused.

Do not load the tool with fasteners

8.

when any one of the operating con-

trols is activated.

Do not remove, tamper with, or other-

9.

wise cause the tool operating controls

to become inoperable.

Do not operate the tool if any portion

10.

of the tool operating controls is inop-

erable, disconnected, altered, or not

working properly.

Disconnect the tool from the power

11.

source when:

Unattended.

a.

Performing any maintenance or

b.

repair.

Clearing a jam.

c.

Moving the tool to a new location.

d.

The written approval of the tool man-

12.

ufacturer must be obtained prior to

making any modifications to the tool.

Refer to the tool maintenance instruc-

13.

tions for detailed information on the

proper maintenance of the tool.