Troubleshooting – Harbor Freight Tools 45949 User Manual

Page 8

Page 8

SKU 45949

7.

Adjust the air pressure from the Control Filter Knob on the back panel.

Caution: Verify that no wires, cables, or other obstructions are below the cutting area.

8.

Place the Torch Head on the metal to be cut and press the Start button on the Torch

handle.

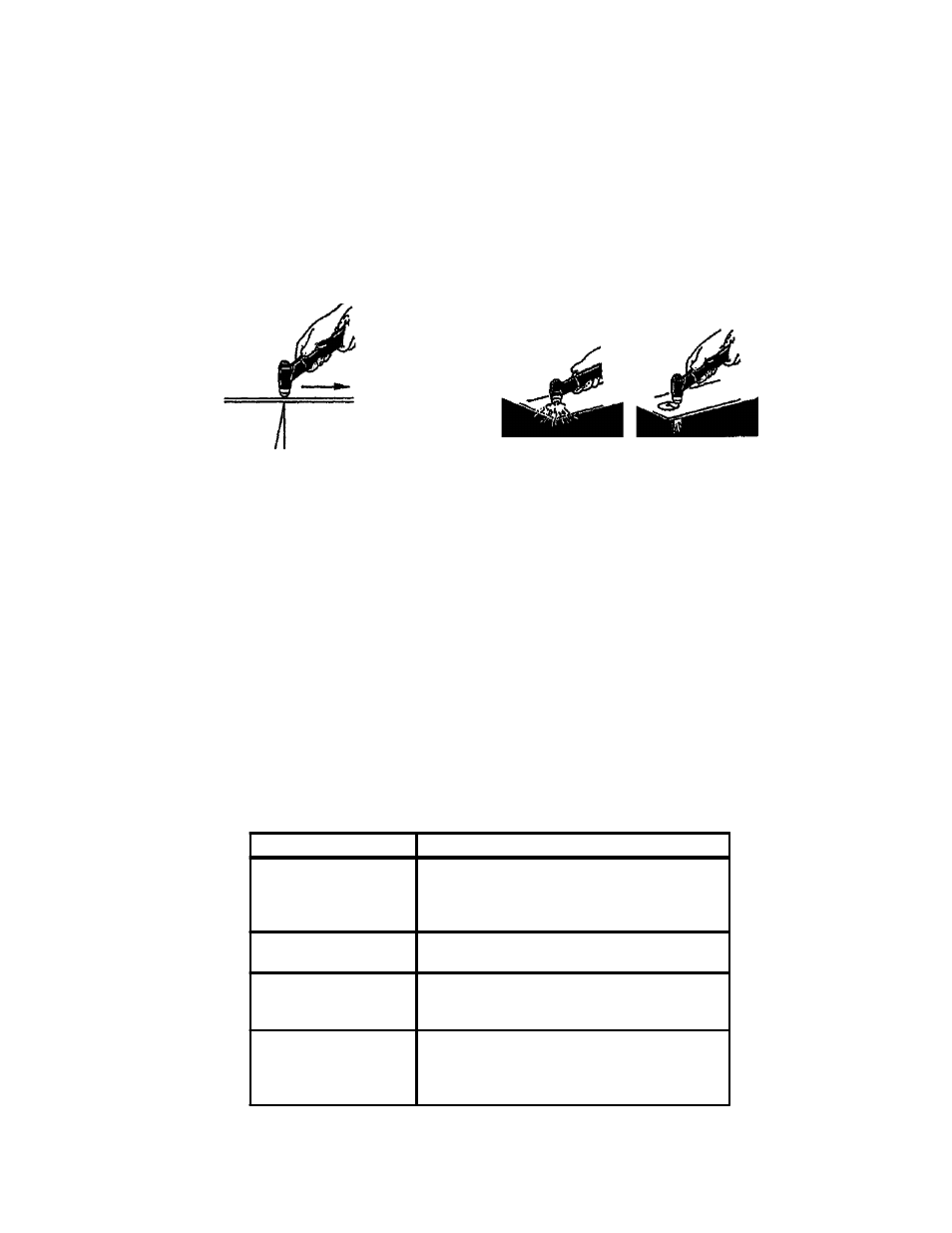

Start to cut slowly, then increase the speed to obtain the desired cut quality. Regulate

the speed to obtain a good cut. See illustration “A” below. Air plasma will create a

straight arc with stainless steel or aluminum, or a 5” arc with softer steel. The arc varies

depending on speed, material, and thickness.

In some cutting operations, it may be necessary to start the cut from a point away from

the edge. See illustration “B” above. The backfire from this operation could shorten the

life of the torch components, so it is recommended to do this cut as fast as possible.

Slightly incline the Torch so that the backfire particles are blown away by the nozzle

(and by the operator), instead of bouncing back into the Torch. Clean away slag and

incrustations from the Torch Head. Spraying or immersing the Torch Head in an anti-

slag substance, minimizes the quantity of incrustation that would stick to it.

9.

When the cutting process is complete, release the Start button on the Torch handle,

place the Torch handle in a safe place, and wait 5 minutes before turning the On/Off

switch to “O” to allow proper cooling. The pilot arc is automatic, not manually

controlled. Handle the torch components with care and protect them from damage.

10.

Unplug the line cord from the electrical outlet.

Troubleshooting

SYMPTION

POSSIBLE CAUSE

Insufficient penetration

1. Cutting speed too fast

2. Not enough amperage or air pressure

3. Workpiece too thick

4. Torch components damaged or worn

Main arc goes out

1. Cutting speed too slow

2. Nozzle is too far from the workpiece

Slag formation

1. Wrong gas pressure

2. Wrong cutting power

3. Torch components damaged or worn

Burned nozzle

1. Cutting power too high

2. Nozzle damaged or loose

3. Nozzle touching the workpiece

4. Excessive slag; Low gas plasma pressure

A

B

REV 06/03