Operating instructions – Harbor Freight Tools 99623 User Manual

Page 7

Page 7

SKU 99623

For technical questions, please call 1-800-444-3353.

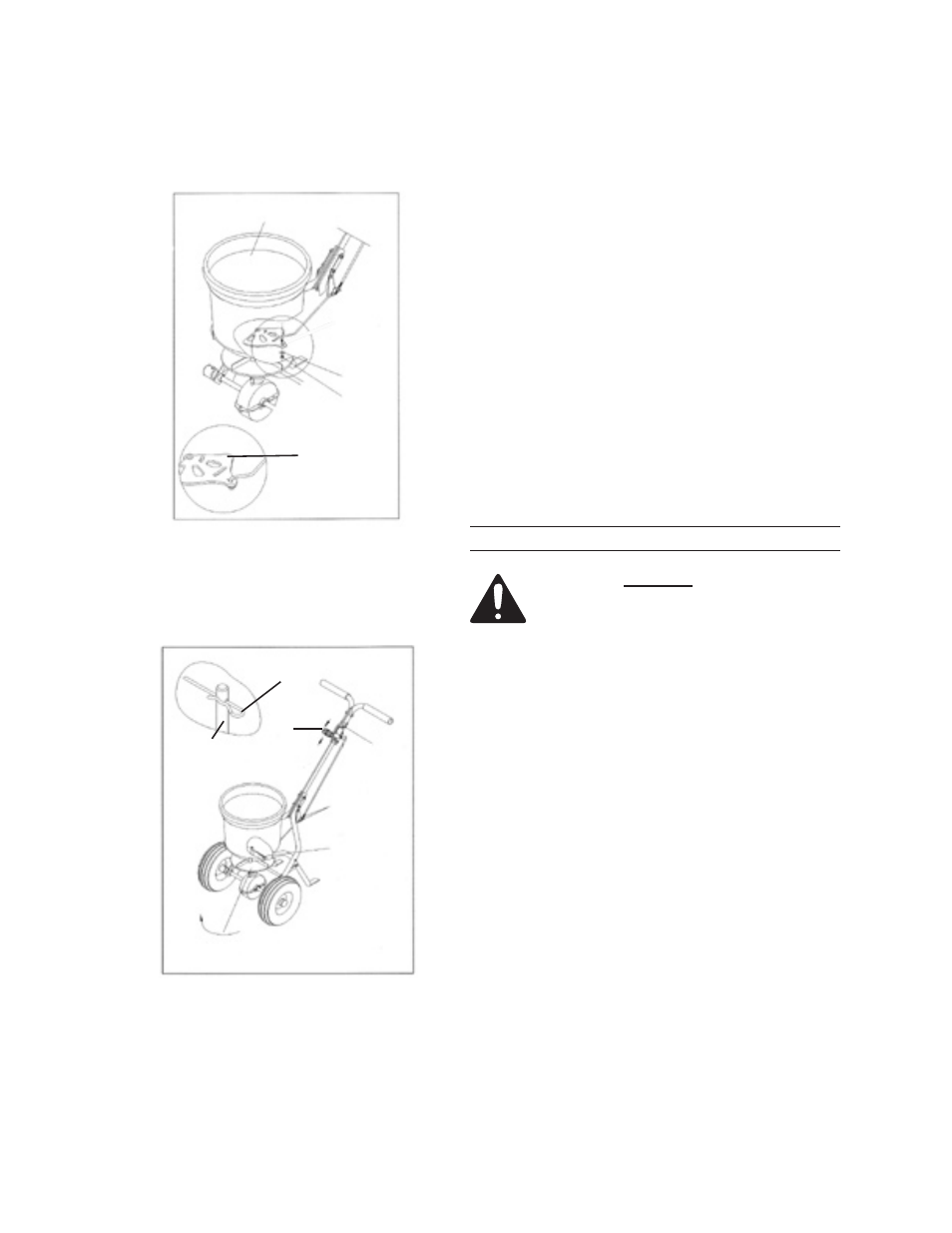

one Lock Nut (24).

(See Figure I.)

FIguRE I

HOPPER

(16)

FLAT

WASHER

(48)

LOCK

NuT

(24)

10. Push down on the Adjust Handle (6)

to its lowest position.

(See Figure J.)

FIguRE J

“R” PIN (17)

“R” PIN

(17)

WINg

NuT

(10)

LOCK NuTS

(24)

PuSH FORWARD.

IMPELLER MuST TuRN

IN THIS DIRECTION.

ADJuST

HANDLE

(6)

PINION

SHAFT

11. Adjust the position of the two Lock

Nuts (24) on the Control Rod (25),

making sure the holes at the bottom

of the Hopper (16) line up with the

holes in the Shut Off Plate (27) prop-

erly.

(See Figures I and J.)

Pull up on the Adjust Handle (6) to its

12.

upper position, making sure the holes

in the Hopper (16) and the holes in the

Shut Off Plate (27) are 100% open.

(See Figure J.)

Adjust the position of the Wing Nut

13.

(10). By doing so, you are able to con-

trol the size of the holes you need.

(See Figure J.)

Insert the “R” Pin (17) into the Pinion

14.

Shaft on the Gear Box and Axle As-

sembly (39). Make sure the Impeller

(42) is turning in the correct direction as

indicated by the arrow in the illustration.

(See Figure J.)

OPERATINg INSTRuCTIONS

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section

at the beginning of this manual

including all text under

subheadings therein before

assembly or use of this product.

Before operating the Spreader make

1.

sure to wear ANSI-approved safety

impact glasses, NIOSH-approved dust

mask/respirator, and heavy duty work

gloves.

Remove the Screen (14) on the Hopper

2.

(16) and fill the Hopper with the materi-

al you wish to apply. Do not exceed 50

pounds of material. Then replace the

Screen.

(See Figure K, next page.)

Refer to the manufacturer’s recom-

3.

mended flow rate (0 to 5, typically

shown on the bag/container of the

material being applied).

Adjust the flow rate on the Gauge and

4.

Lever Assembly (4) to that of the mate-

SHuT OFF PLATE

(27)