6. changing gun contact tip – Hobart Welding Products OM-1594 User Manual

Page 39

OM-1594 Page 35

6-6.

Changing Gun Contact Tip

1

Contact Tip Wrench

2

Nozzle

Insert wrench into nozzle over

contact tip.

3

Compression Nut

4

Contact Tip

Loosen nut. Pull out contact tip.

Install new contact tip.

Tighten nut just until contact tip is

secure. Overtightening nut will

damage adapter.

150 437

1

3

4

2

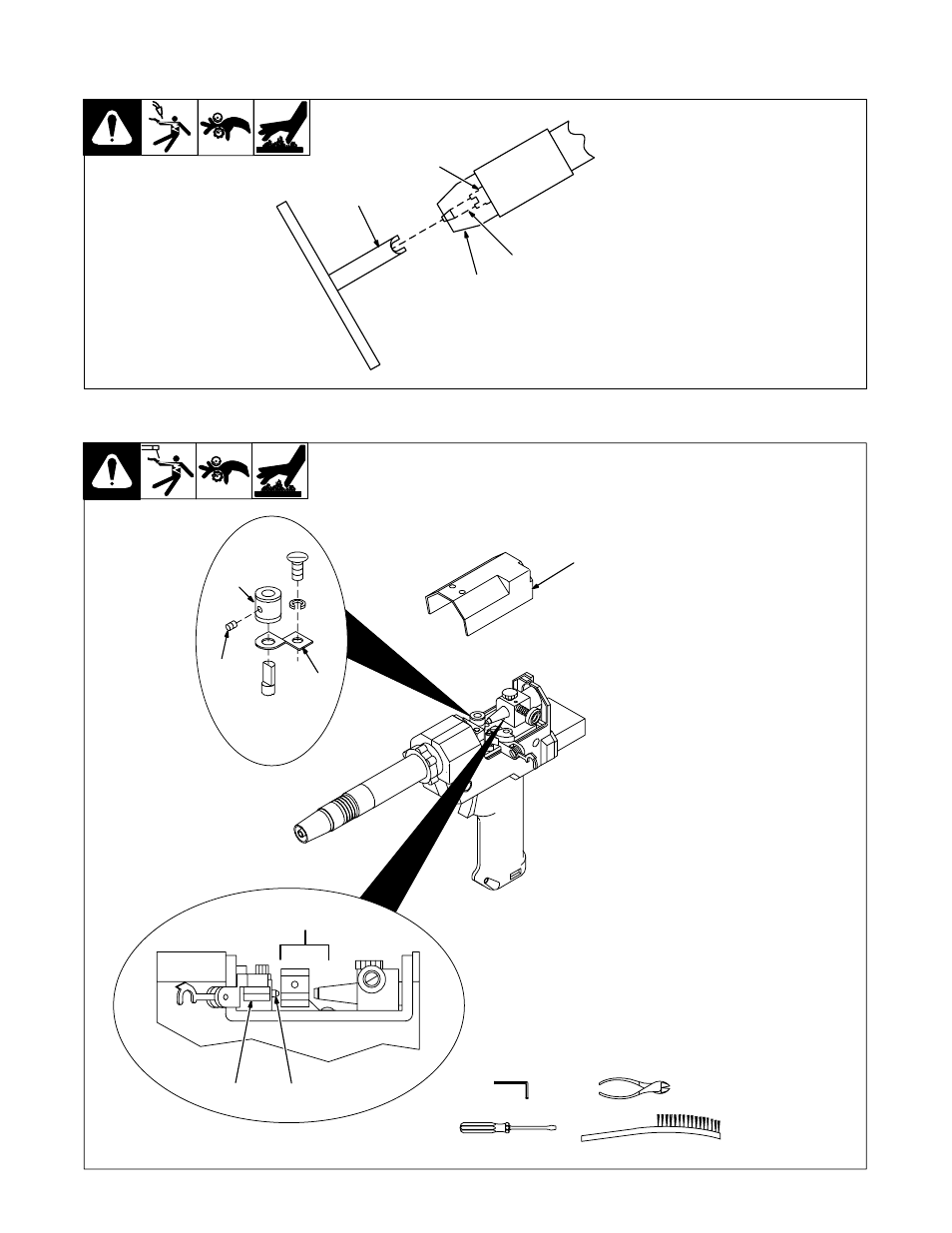

6-7.

Replacing Or Cleaning Gun Drive Roll In Pistol-Grip Guns

Turn Off wire feeder and welding

power source.

1

Top Cover

2

Pressure Roll Assembly

Cut off wire where it enters

pressure roll assembly area.

3

Setscrew

4

Current Pick-Up Tab

This tab helps prevent burnback

caused by welding arcs inside the

contact tip. This tab may be re-

moved to provide an insulated drive

roll. (If tab is removed, a smaller di-

ameter contact tip is recom-

mended. See options in Parts List.)

Lightly grease top of tab before rein-

stalling.

5

Drive Roll

Use wire brush to clean drive roll.

Install drive roll with desired groove

down, and turn drive roll so one

setscrew faces flat side of shaft.

6

Bearing

7

Liner

Line up drive roll groove with bear-

ing groove and liner opening.

Tighten setscrews.

If changing drive roll in feeder, see

Section 6-1.

Thread welding wire through gun,

and adjust drive roll pressure, if

necessary (see Section 4-14).

Close and secure pressure roll

assembly. Reinstall top cover.

Ref. 151 599-C

Tools Needed:

5/64 in

2

6

7

1

5

3

4