Maintenance and servicing – Harbor Freight Tools CENTRAL MACHINERY 65345 User Manual

Page 17

Page 17

SKU 65345

For technical questions, please call 1-800-444-3353.

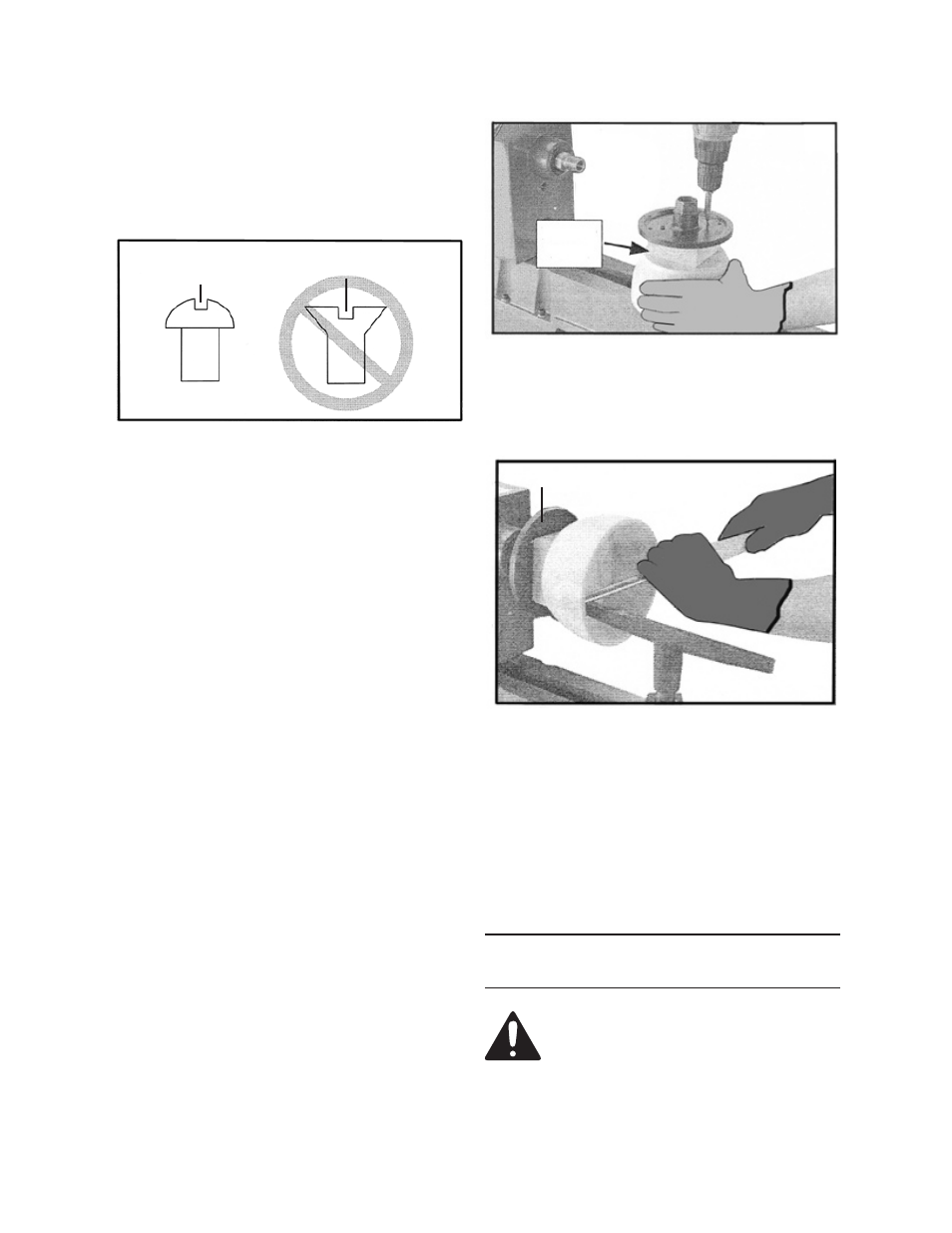

Center the Faceplate (13) on the

15.

workpiece and attach it through the

Faceplate mounting holes with non-

tapered head wood screws.

(See Figure T.)

FIgurE T

uSE

ONLY

NON-TApErED

WOOD ScrEWS

DO NOT uSE

TApErED HEAD

ScrEWS

16. NOTE: Faceplate turning is typically

done with open-faced workpieces like

bowls. If screws cannot be placed in

the workpiece, then a backing block

can be glued to the workpiece and

attached to the Faceplate (13) with

screws.

(See Figure u.)

To mount the workpiece to a backing

17.

block, make the backing block from

a piece of scrap wood that is flat on

both sides.

(See Figure u.)

Mark the center of the backing block.

18.

(See Figure u.)

Drill a 14” diameter hole through the

19.

center of the backing block.

(See Figure u.)

Glue the center of the backing block

20.

to the center of the workpiece. Clamp

the backing block to the workpiece,

and wait for the glue to dry according

to the glue manufacturer’s recom-

mendation.

(See Figure u.)

FIgurE u

BAcKINg

BLOcK

21. Thread the Faceplate (13) onto the

Headstock Spindle (14) and tighten

securely.

(See Figure V.)

FIgurE V

FAcEpLATE

(13)

FAcEpLATE TurNINg prOcEDurE

22. After turning, the workpiece can be

sanded and finished before remov-

ing it from the Lathe. IMPORTANT:

Whenever sanding or finishing, re-

move the Tool Rest (35) to increase

safety and gain adequate working

room.

MAINTENANcE AND

SErVIcINg

Procedures not specifically

explained in this manual

must be performed only by a

qualified technician.