Beacon controller, Beacon, Service diagnosis chart – Heatcraft Refrigeration Products 25001501 User Manual

Page 19

BEACON CONTROLLER

19

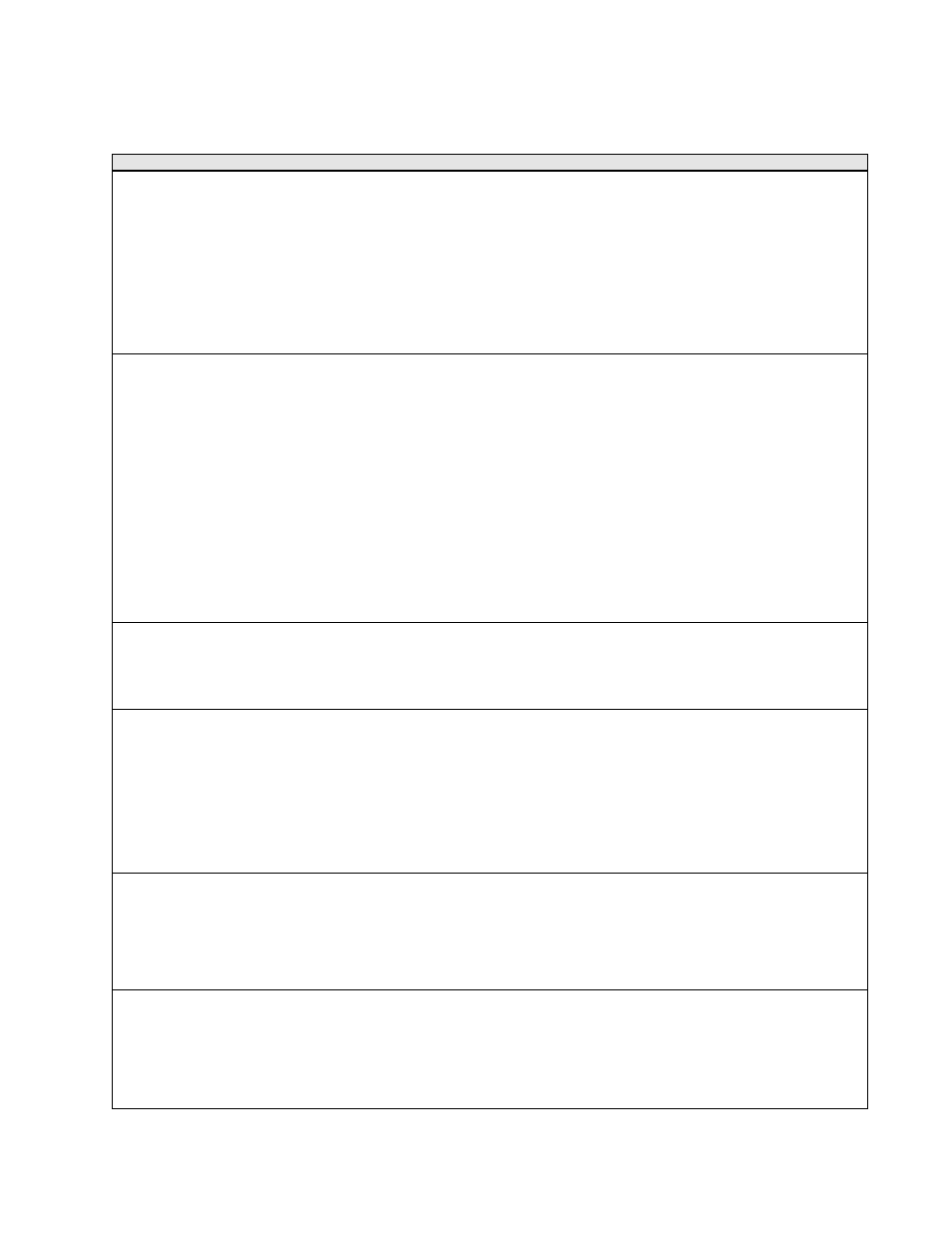

SERVICE DIAGNOSIS CHART -

BEACON

PROBLEM

POSSIBLE CAUSE

POSSIBLE CORRECTIVE ACTION

Compressor will not run

1. 4 min. off cycle

1. Wait 4 min.

2. Box temp is below t’stat setting

2. Lower t’stat setting

3. Loose wiring

3. Check all wire terminals; tighten if necessary.

4. Bad sensor

4. Check status light for problem sensor

5. Discharge temp. too high

5. Check general diagnosis chart

6. Beacon board defective

6. Check “Status” light; if out, replace board

7. Low pressure switch open

7. Check pressure switch setting.

8. Supply voltage too low

8. Change transformer primary to correct supply

voltage tap. 208 or 240 volts.

9. Evap coil temp too high

9. Temporarily disconnect “Evap Coil” sensor from

board; reconnect when coil temp is lowered

Cannot get to box temp

1. Wrong t’stat setting

1. Check and adjust t’stat

2. Wrong selection on board

2. For box temp of 20

°

F and above, select

“MEDIUM”; for box temp below 20

°

F,

select “LOW”

3. Comp. run time too short

3. a) Increase time between defrost. b) May need

time delay across low pressure switch. (See

“Compressor cycles off at startup” below.)

4. Bad expansion valve

4. Check if expansion valve is operating

5. Wrong charge

5. Check charging procedure

6. Box temp fluctuate

6. Allow system to run longer

7. Evap coil iced up

7. Clear ice and check defrost setting

8. Wrong nozzle

8. Check if distributor tubes are sweating evenly; if

not, have factory check nozzle selection for

application.

9. Low pressure switch

9. EXV closing down due to low superheat; check

tripping compressor

“EVAP IN” & “EVAP OUT” sensors; check

refrigerant charge.

Superheat light indicates

1. Incorrect refrigerant charge

1. Check refrigerant charge

1 deg then 8 deg

2. Expansion valve oversized

2. Check expansion valve size

3. Superheat set too low

3. Raise superheat setting

4. System not stabilized

4. Allow system to run longer

5. Evap coil iced up

5. Clear ice

Freezer coil icing

1. Insufficient refrigerant.

1. Check system for leaks; repair leaks &

add refrigerant

2. Wrong defrost termination setting

2. Raise setting on the board

3. Wrong defrost fail-safe setting

3. Raise setting on the board

4. Evap fan not running

4. Check fan circuit and board relay

5. Defrost heater not working

5. Check heater circuit and board relay

6. Faulty defrost termination sensor

6. Check sensor on evap coil

7. Not enough defrost for

conditions or infiltration

8. Undersized system

Compressor Cycles off at

1. Low pressure switch setting

1. Change low pressure cutout to 0 PSIG

startup w/o pumping down

too high

and 10 PSIG cut-in

2. Low pressure switch

2a.EXV closing down due to low superheat; check

tripping compressor

“EVAP IN” & “EVAP OUT” sensors

3. Compressor out on thermal

2b.Check refrigerant charge.

overload protector

2c.Check if sensors are connected to correct

terminals on Beacon board.

Unit Cycles on and off

1. Incorrect wiring

1a.Check wiring

without 4 min. time delay

1b.Bad Beacon board

2. Low pressure switch

2a.EXV closing down due to low superheat; check

tripping compressor

“EVAP IN” & “EVAP OUT” sensors

3. Time delay bad or

2b.Check refrigerant charge.

not set for 2 minutes

2c.Check if sensors are connected to correct

terminals on Beacon board.