Edelbrock 1910 User Manual

Page 3

Page 3 of 4

©2002 Edelbrock Corporation

Brochure No. 63-0149

Rev. 10/02

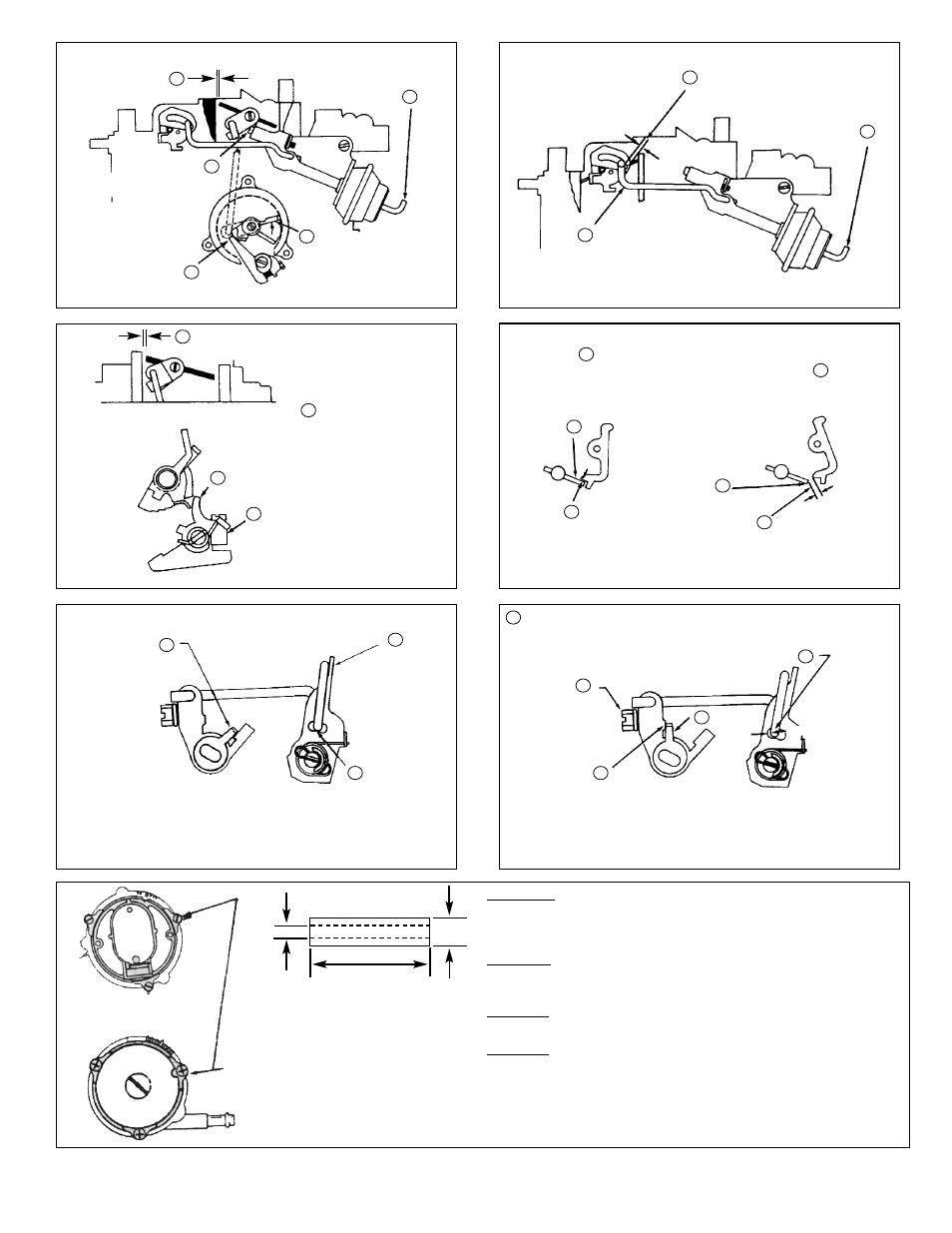

FRONT VACUUM BREAK ADJUSTMENT

AIR VALVE ROD ADJUSTMENT

UNLOADER ADJUSTMENT

SECONDARY OPENING ADJUSTMENT

SECONDARY CLOSING ADJUSTMENT

REMOVE & REPLACING TAMPER RESISTANT CHOKE COVER

SECONDARY THROTTLE LOCK-OUT ADJUSTMENT

MEASURE DISTANCE

BETWEEN UPPER EDGE

OF CHOKE VALVE AND

AIR HORN WALL.

BUBBLE ON ANGLE GAUGE

SHOULD BE CENTERED.

SEE FIG. 7

TO ADJUST TURN

SCREW

PLACE CAM FOLLOWER ON

HIGH STEP OF FAST IDLE

CAM.

TAPE PURGE BLEED HOLE IN

COVER. (WHEN USED). APPLY

OUTSIDE VACUUM SOURCE

TO FULLY SEAT DIAPHRAGM.

TO ADJUST

BEND ROD

MEASURE BETWEEN UPPER EDGE OF

CHOKE VALVE AND AIR HORN WALL.

STEP A

CHOKE VALVE AND THROTTLE VALVES

CLOSED.

STEP B

CHOKE VALVE HELD WIDE OPEN BY

PUSHING DOWN ON TAIL OF FAST

IDLE CAM.

TO ADJUST BEND

LOCKOUT PIN.

MEASURE DISTANCE

BETWEEN LOCK-OUT PIN AND

LOCK-OUT LEVER.

MEASURE DISTANCE BETWEEN

END OF LOCK-OUT PIN &

LOCK-OUT LEVER.

TO ADJUST FILE

END OF PIN.

(.015” CLEARANCE)

(.015” CLEARANCE)

CLOSE CHOKE VALVE BY

PUSHING UP ON TANG ON

VACUUM BREAK LEVER.

(BUBBLE ON ANGLE GAUGE

SHOULD BE CENTERED).

TO ADJUST

BEND TANG.

THROTTLE VALVES HELD IN

WIDE OPEN POSITION.

OPEN PRIMARY THROTTLE SLOWLY

UNTIL ACTUATING LINK CONTACTS

TANG.

TO ADJUST

BEND TANG.

TO ADJUST

BEND TANG.

LINK SHOULD BE IN

CENTER OF SLOT.

2 0’CLOCK

POSITION

3/16”

1/8”

3/4”

ADAPTER MADE

FROM STEEL TUBING

DISASSEMBLY: CAREFULLY ALIGN A #21 DRILL (.159 ”) ON PO RIVET HEADS AND

DRILL ONLY ENOUGH TO REMOVE RIVET HEAD, DRILL ALL RIVET HEADS (3) AND

USE A DRIFT PUNCH AND HAMMER TO DRIVE THE REMAINDER OR THE RIVETS OUT

OF THE CHOKE HOUSING. REMOVE CHOKE COMPONENTS.

REASSEMBLY: PLACE CHOKE CAP IN PLACE AND ROTATE CLOCKWISE UNTIL COIL

TANG ENGAGES LEVER TANG AND CLOSES CHOKE VALVE. IT IS IMPORTANT THAT

THIS ENGAGEMENT IS ACHIEVED FOR PROPER OPERATION.

MODEL 1903: ROTATE AND ALIGN THE NOTCH IN THE COVER WITH THE PROTRUSION

ON THE RETAINER INSTALLED AT THE 2 O’CLOCK POSITION.

MODEL 1904: ROTATE AND ALIGN THE NOTCH IN THE COVER WITH THE RAISED

CASTING BOSS AT THE 2 O’CLOCK POSITION. RETINING THE COVER WITH THE POP

RIVETS PROVIDED IN THE KIT. IT MAY BE NECESSARY TO USE AN ADAPTER (TUBE)

IF INSTALLATION TOOL INTERFERES WITH THE ELECTRICAL CONNECTION TOWER IN

THE CHOKE COVER.

TURN CLOCKWISE

FOR RICHER SETTING

CHOKE VALVE WIDE OPEN FAST

IDLE CAM FREE OF CAM

FOLLOWER.

CURB IDLE SET TO

PROPER RPM

LEVER AGAINST TANG.

MEASURE DISTANCE BETWEEN

ROD AND SLOT IN LEVER.

(.020” CLEARANCE)

AIR VALVE COMPLETELY

CLOSED. MEASURE DISTANCE

BETWEEN ROD AND END OF

SLOT IN LEVER

TAPE PURGE BLEED HOLE IN

COVER (WHEN USED). APPLY

OUTSIDE VACUUM SOURCE TO

FULLY SEAT DIAPHRAGM

PUSH UP ON INSIDE CHOKE COIL

LEVER UNTIL TANG ON

INTERMEDIATE CHOKE SHAFT

CONTRACTS TANG ON VACUUM

BREAK PLUNGER STEM

Fig. 9

Fig. 10

Fig. 11

Fig. 13

Fig. 14

Fig. 15

Fig. 12

3

4

2

3

2

3

4

1

3

2

1

2

3

1

1

3

2

2

1

5

3

4

2

1

5

1

(ON CAR)

(ON CAR)