Edelbrock 1910 User Manual

Page 2

Page 2 of 4

©2002 Edelbrock Corporation

Brochure No. 63-0149

Rev. 10/02

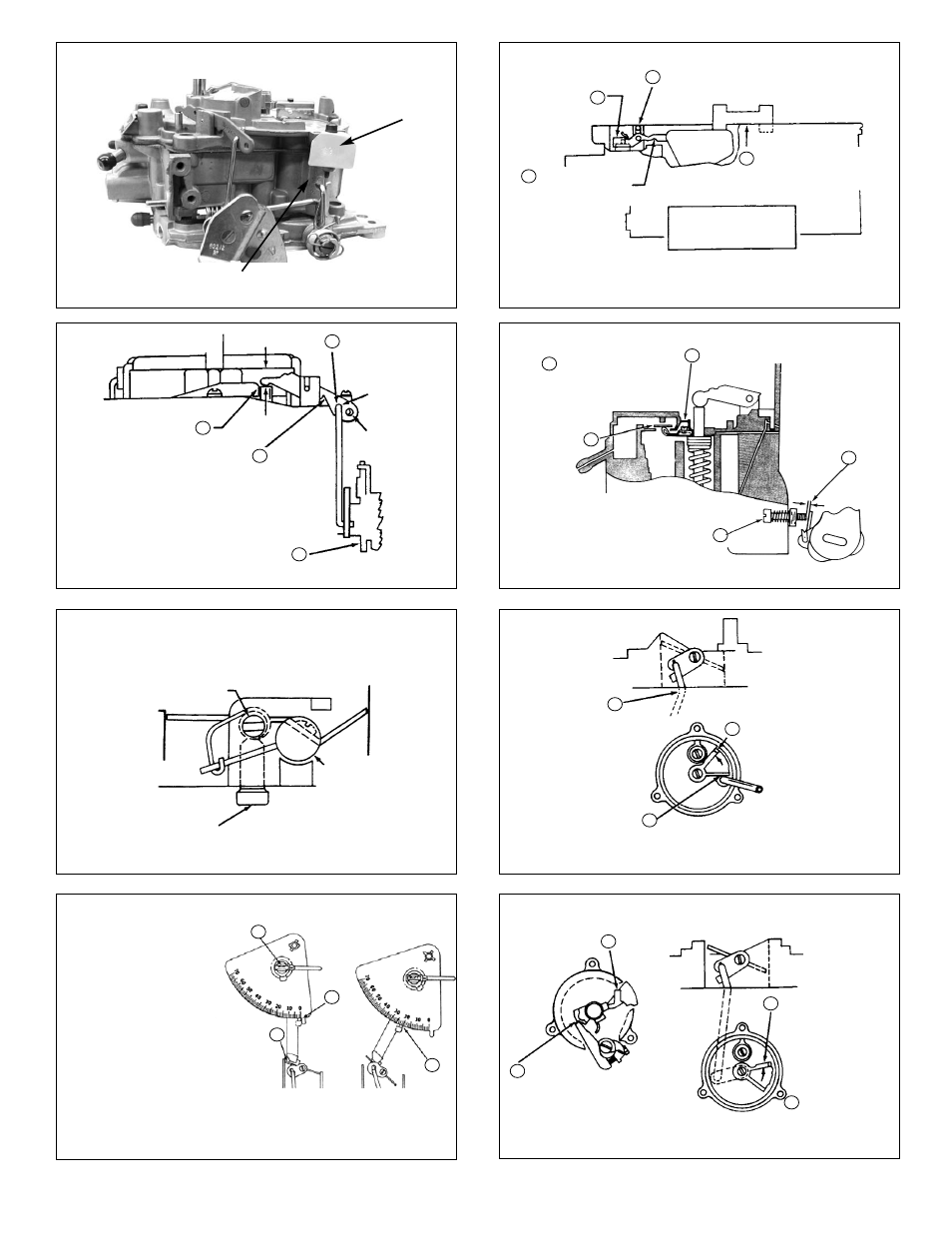

ALUMINUM TAG

WITH EDELBROCK’S

MODEL NUMBER.

MANUFACTURER’S NUMBER.

PRESS DOWN GENTLY

ON FLOAT TANG UNTIL

SEATED ON NEEDLE.

HOLD FLOAT HINGE

PIN FIRMLY IN PLACE.

TO ADJUST, BEND

FLOAT UP OR DOWN.

INSTALL PUMP ROD

IN PROPER HOLE.

VENT VALVE COVER AND SPRING

REMOVED, CHOKE OPEN POSITION,

FAST IDLE CAM FREE.

TO ADJUST, REMOVE PLUG AND

TURN HEX SCREW. REPLACE PLUG

AFTER ADJUSTMENT.

PLACE .075” GAUGE

BETWEEN IDLE STOP

SCREW AND THROTTLE

LEVER TANG.

GAUGE IN PLACE,

VENT VALVE SHOULD

BE CLOSED, GAUGE

REMOVED, VENT

VALVE SHOULD BE

OPEN.

BACK OUT THROTTLE STOP SCREW.

THROTTLE VALVES COMPLETELY

CLOSED. TURN THROTTLE STOP SCREW

IN UNTIL IT CONTACTS TANG ON

THROTTLE LEVER. THEN TURN SCREW

IN 1 1/2 TURNS.

TO ADJUST

BEND ROD.

PUSH UP ON CHOKE COIL LEVER

UNTIL CHOKE VALVE IS CLOSED.

INSERT .120” GAUGE IN HOLE.

LOWER EDGE OF LEVER SHOULD

JUST TOUCH GAUGE.

TO ADJUST SUPPORT

PUMP LEVER ON PUMP

END AND BEND LEVER ON

PUMP ROD SIDE.

BACK OUT THROTTLE STOP

SCREW THROTTLE VALVES

HELD CLOSED.

TO ADJUST LOOSEN ALLEN LOCK SCREW. AIR VALVE HELD CLOSED. TURN ADJUSTING SCREW

CLOCKWISE UNTIL TORSION SPRING CONTACTS PIN ON AIR VALVE SHAFT. THEN TURN

ADDITIONAL SPECIFIED TURNS AND TIGHTEN ALLEN LOCK SCREW.

(ADJUSTMENT SPECIFICATIONS TABLE)

CAUTION:

PLACE CARBURETOR ON

HOLDING FIXTURE SO THAT IT WILL

REMAIN IN SAME POSITION WHEN GAUGE

IS USED.

1. ROTATE DEGREE SCALE UNTIL ( 0 ) IS

OPPOSITE POINTER

2. CHOKE VALVE HELD COMPLETELY

CLOSED. PLACE MAGNET SQUARELY

ON TOP OF CHOKE VALVE.

3. ROTATE BUBBLE UNTIL IT IS

CENTERED.

4. ROTATE SCALE SO THAT DEGREE

SPECIFIED FOR ADJUSTMENT IS

OPPOSITE POINTER.

5. FOLLOW NUMERICAL OUTLINE IN

MAKING ADJUSTMENT, INSTEAD OF

MEASURING GAP AT EDGE OF CHOKE

VALVE. MAKE ADJUSTMENT TO BRING

BUBBLE BACK TO CENTER POSITION.

GAUGE: J-26701 KENT MOORE TOOL

BT-7704 BORROUGHS TOOL

PLACE CAM FOLLOWER

ON SECOND STEP OF

FAST IDLE CAM NEXT

TO HIGH STEP.

TO ADJUST,

BEND TANG ON

FAST IDLE CAM

FOLLOW GAUGE SET

PROCEDURE FIG.

7

PUSH UPWARD ON

CHOKE COIL LEVER,

MOVING CHOKE TOWARD

CLOSED POSITION UNTIL

STOP IS MADE.

( BUBBLE ON ANGLE

GAUGE SHOULD BE

CENTERED.)

SPRING ADJUSTING

SCREW.

AIR VALVE SHAFT.

ALLEN LOCK SCREW.

MEASURE FROM TOP OF

CHOKE VALVE WALL TO

TOP OF PUMP STEM.

INNER.

OUTER.

BOWL COVER GASKET REMOVED

MEASURE FROM TOP OF CASTING

TO TOP OF FLOAT 3/16” IN

FROM TOE OF FLOAT.

CAUTION : DO NOT EXERT

PRESSURE ON RESILIENT

NEEDLE VALVE.

DRY FLOAT LEVEL ADJUSTMENT

CARBERUTOR IDENTIFICATION

ACCEL. PUMP ROD ADJUSTMENT

AIR VALVE SPRING ADJUSTMENT

ANGLE GAUGE METHOD

FAST IDLE CAM (CHOKE ROD) ADJUSTMENT

BOWL VENT VALVE ADJUSTMENT

CHOKE COIL LEVER ADJUSTMENT

2

1

4

1

3

4

2

2

3

1

4

4

1

2

3

1

2

1

2

3

3

4

5

3

Fig. 2

Fig. 1

Fig. 3

Fig. 5

Fig. 7

Fig. 8

Fig. 4

Fig. 6