0 description and specifications, 1 overview, 2 priciple of measurement – Emerson 7003M User Manual

Page 13: 3 sensors, Mode/function, Model 7003m

Operator Manual

748223-K

June 2002

Rosemount Analytical Inc. A Division of Emerson Process Management

Description and Specifications 1-1

Model 7003M

SECTION 1

DESCRIPTION AND SPECIFICATIONS

1-1 OVERVIEW

The Model 7003M Percent Oxygen Analyzer

continuously monitors the concentration of

oxygen in a gaseous sample. It consists of a

sensor and the analyzer. The sensor is

housed in a chamber assembly and is

connected to the analyzer by a shielded multi-

conductor cable.

The Model 7003M Percent Oxygen Analyzer

provides direct digital readout, isolated current

output, automatic temperature compensation

circuitry, and dual relay contact closures for

alarms or ON/OFF control devices as

standard features. The alarm ranges can be

selected independently from the output range,

eliminating the need to readjust alarm

setpoints if the range is changed.

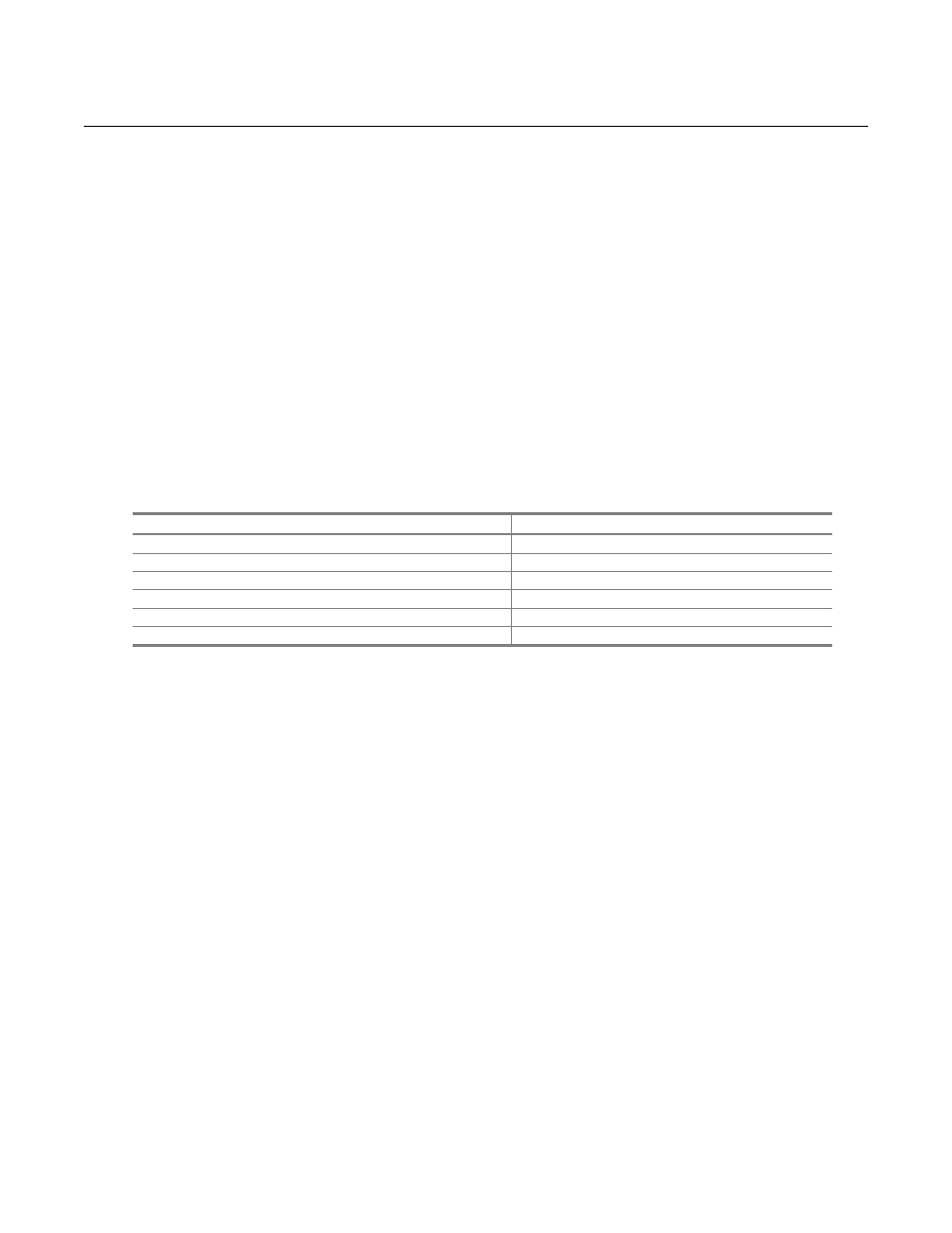

The analyzer has six modes of operation:

MODE

FUNCTION

RUN (see Section 3-4 on page 3-10)

Normal monitoring

SETUP (see Section 3-5 on page 3-11)

Changing parameters

ALARM/CONTROL (see Section 3-6 on page 3-16)

Set alarms or ON/OFF controllers

CALIBRATION (see Section 4-2 on page 4-1)

Gas calibration/pressure inputs

HOLD (see Section 4-3 on page 4-5)

Retain last output value

DIAGNOSTICS (see Section 4-4 on page 4-8)

Electronics checks

The Model 7003M Percent Oxygen Analyzer

is housed in a NEMA 4X (CSA enclosure 4),

corrosion resistant housing suitable for panel,

pipe or wall mounting.

The analyzer has a microprocessor controlled

keyboard for operation. Signals from the

remote oxygen and temperature sensors are

processed to compute real time oxygen

concentration corrected for temperature,

constant pressure differences and residual

sensor current. The oxygen concentration is

compared with user-set alarm parameters,

and also generates an isolated 4 to 20 or 0 to

20mA signal. Data is stored in a memory

circuit that retains the data in case power is

removed.

The analyzer is shipped from the factory

configured for operation on either 115 VAC or

230 VAC, 50/60 Hz as specified by the

customer when ordered.

1-2 PRINCIPLE OF MEASUREMENT

Measurement is based on the electro-

chemical reaction between oxygen and the

sensor cathode which produces a low level

electrical current. The sensor signal is

proportional to the partial pressure of oxygen

present at the membrane. This signal and a

thermistor signal are received by the analyzer

and processed by the electronics to output a

calibrated oxygen signal that is compensated

for temperature.

1-3 SENSORS

Rosemount Analytical offers rechargeable and

disposable oxygen sensors which can be

used with the Model 7003M. These sensors

are supplied in kits: Submersion, in-line flow,

fast response, and a cell separation kit.

Sensors are available constructed of

polypropylene or Ryton. See Section 7-

4REPLACEMENT PARTS - SENSORS on

page 7-3, for additional information.