Open loop ground water systems – Envision Peripherals Water-Furnace IM1609 10 User Manual

Page 18

17

ENVISION CONSOLE INSTALLATION MANUAL

Open Loop Ground Water Systems

Always maintain water pressure in the heat exchanger by placing water control valves at the outlet of the unit to prevent

mineral precipitation. Use a closed, bladder-type expansion tank to minimize mineral formation due to air exposure. Insure

proper water flow through the unit by checking pressure drop across the heat exchanger and comparing it to the figures in

unit capacity data tables in the specification catalog. 1.5-2 GPM of flow per ton of cooling capacity is recommended in open

loop applications.

Discharge water from the unit is not contaminated in any manner and can be disposed of in various ways, depending on

local codes, i.e. recharge well, storm sewer, drain field, adjacent stream or pond, etc. Most local codes forbid the use of

sanitary sewer for disposal. Consult your local building and zoning departments to assure compliance in your area.

Note: For open loop/groundwater systems or systems that do not contain an antifreeze solution, set SW1-Switch #2 to the

“WELL” position

(Refer to the Dip Switch Field Selection table). Slow opening/closing solenoid valves (type VM) are recom-

mended to eliminate water hammer.

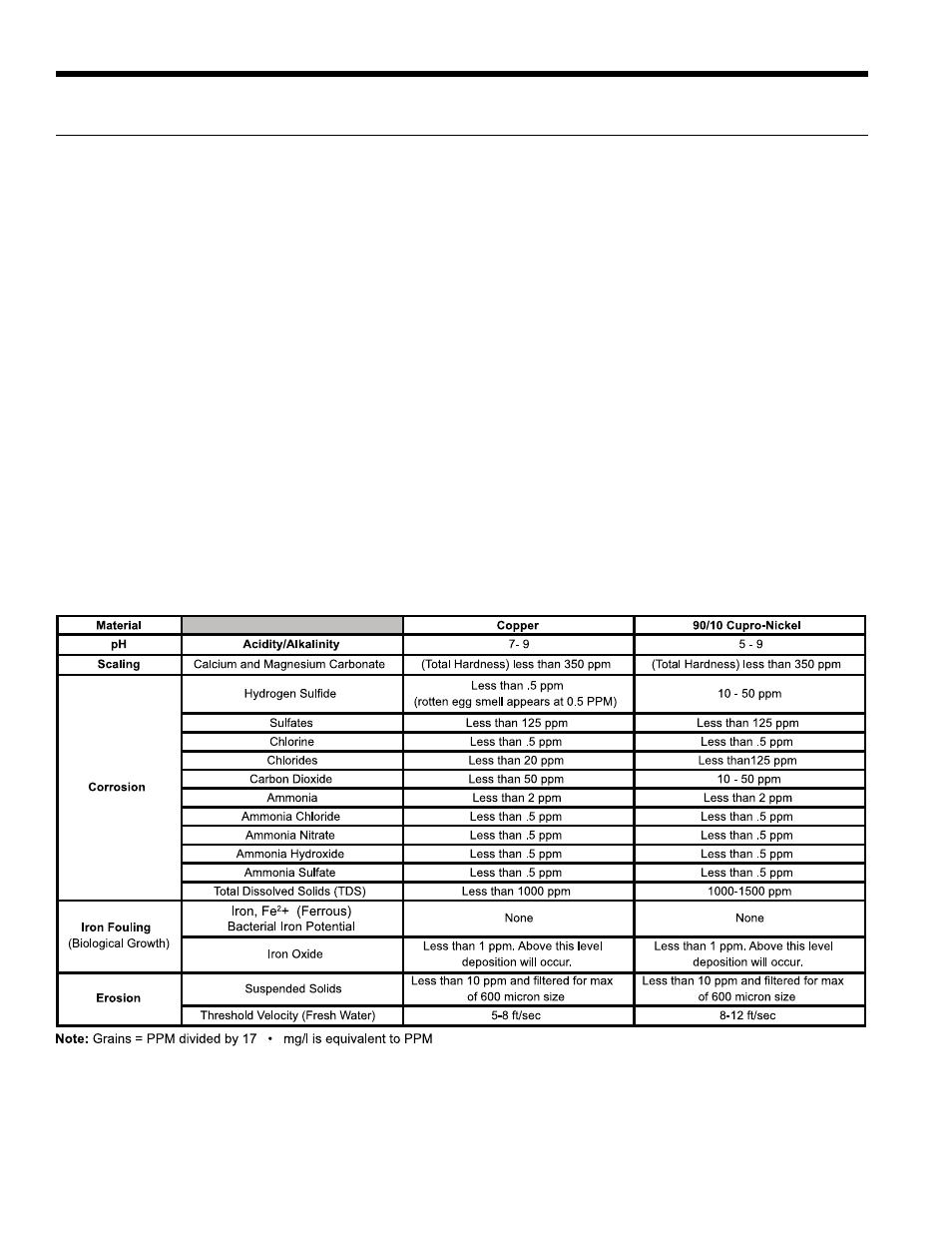

Water Quality

In ground water situations where scaling could be heavy or where biological growth such as iron bacteria will be present,

a closed loop system is recommended. The heat exchanger coils in ground water systems may, over a period of time, lose

heat exchange capabilities due to a buildup of mineral deposits inside. These can be cleaned, but only by a qualified service

mechanic, as special solutions and pumping equipment are required. Desuperheater coils can likewise become scaled and

possibly plugged. In areas with extremely hard water, the owner should be informed that the heat exchanger may require

occasional flushing.

Units with cupronickel heat exchangers are recommended for open loop applications due to the increased resistance to

build-up and corrosion, along with reduced wear caused by acid cleaning.