Assembly – Excell Precision E7540 User Manual

Page 9

9-ENG

A18791

ASSEMBLY

Contents of Carton

1 - Air Compressor

1 - Operator’s Manual

1 - Parts bag containing:

1 - Parts Manual

1 - Parts Manual

4 - 5/8" Washers

Tools Required for Assembly

1 - 9/16" socket or open end wrench

1 - Electric drill

Unpacking

1. Remove

all

packaging.

It may be necessary to brace or support one side of the

outfit when removing the pallet because the air compressor

will have a tendency to tip.

2. Remove and discard the (4) screws and washers holding the compressor to

the pallet.

3. With the help of another person carefully remove air compressor from pallet

and place on a level surface.

To Add Oil To Pump

Compressors are shipped with some oil due to factory

testing. Do not operate this air compressor without adding

the correct amount of oil to the pump crankcase. Serious damage can

result from even the minimal operation if the pump crankcase does not

contain the correct amount of oil. Make sure the break-in procedure is

completed before operating the air compressor.

Multi-Viscosity motor oils, like 10W30, should not be used

in an air compressor. They leave carbon deposits on critical

components, thus reducing performance and compressor life. Use air

compressor oil only.

NOTE: Oil is included with some units. If oil is not included, use an oil

specifically formulated for use in an air compressor, such as Porter-Cable PAS1

air compressor oil. Oil may be found at the store where the air compressor was

purchased.

1. Place unit on a level surface.

Drain tank to release air pressure before removing the oil fill

cap or oil drain plug.

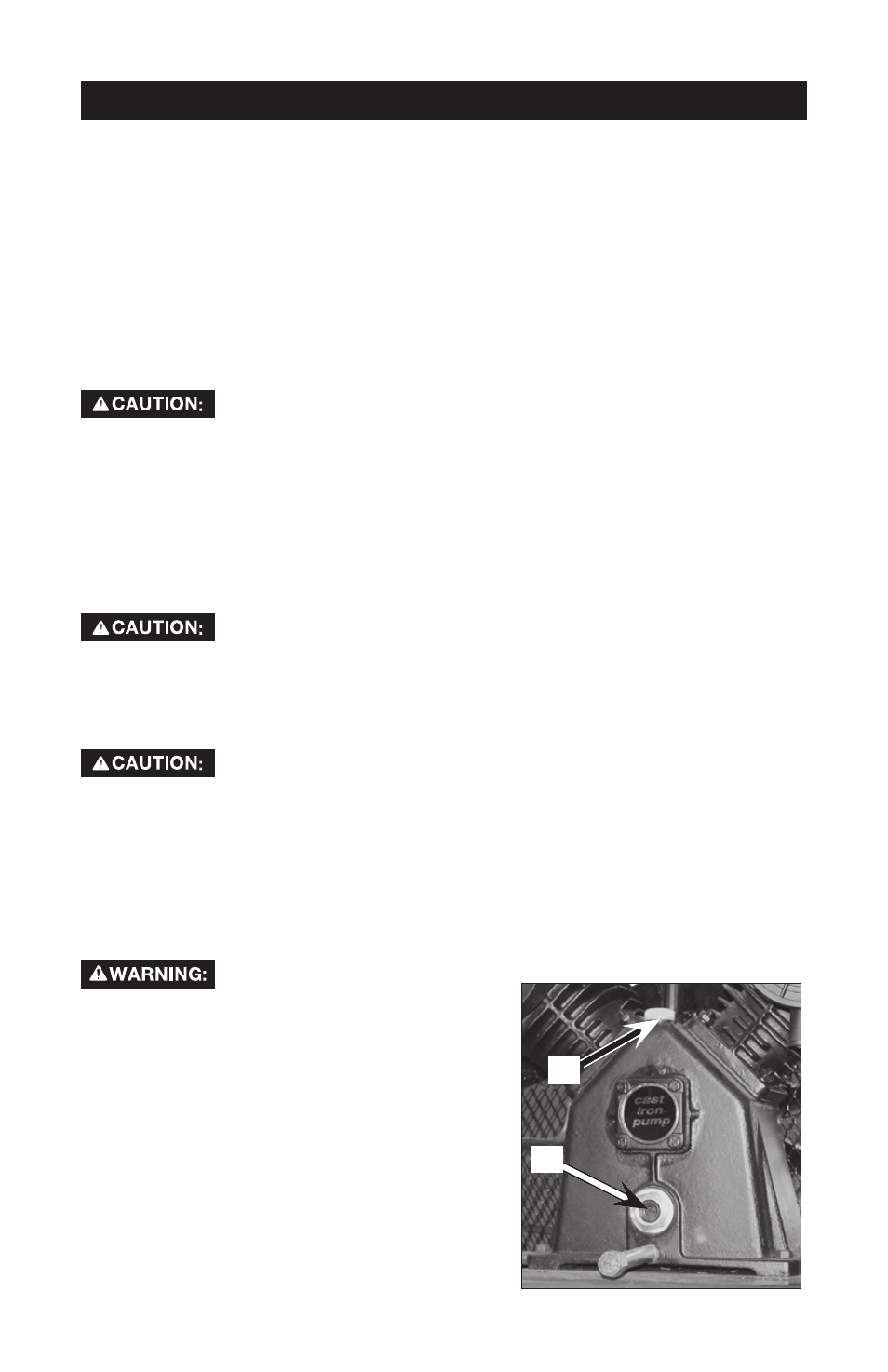

2. Remove oil fill plug (A) and slowly add a

A

B

compressor oil to the middle of sight

glass (B). NOTE: When filling the

crankcase, the oil flows very slowly into

the pump. If the oil is added too quickly,

it will overflow and appear to be full.

NOTE: Crankcase oil capacity is

approximately 48 fluid ounces.

3. Replace oil fill plug.