Excell Precision E7540 User Manual

Page 25

25-ENG

A18791

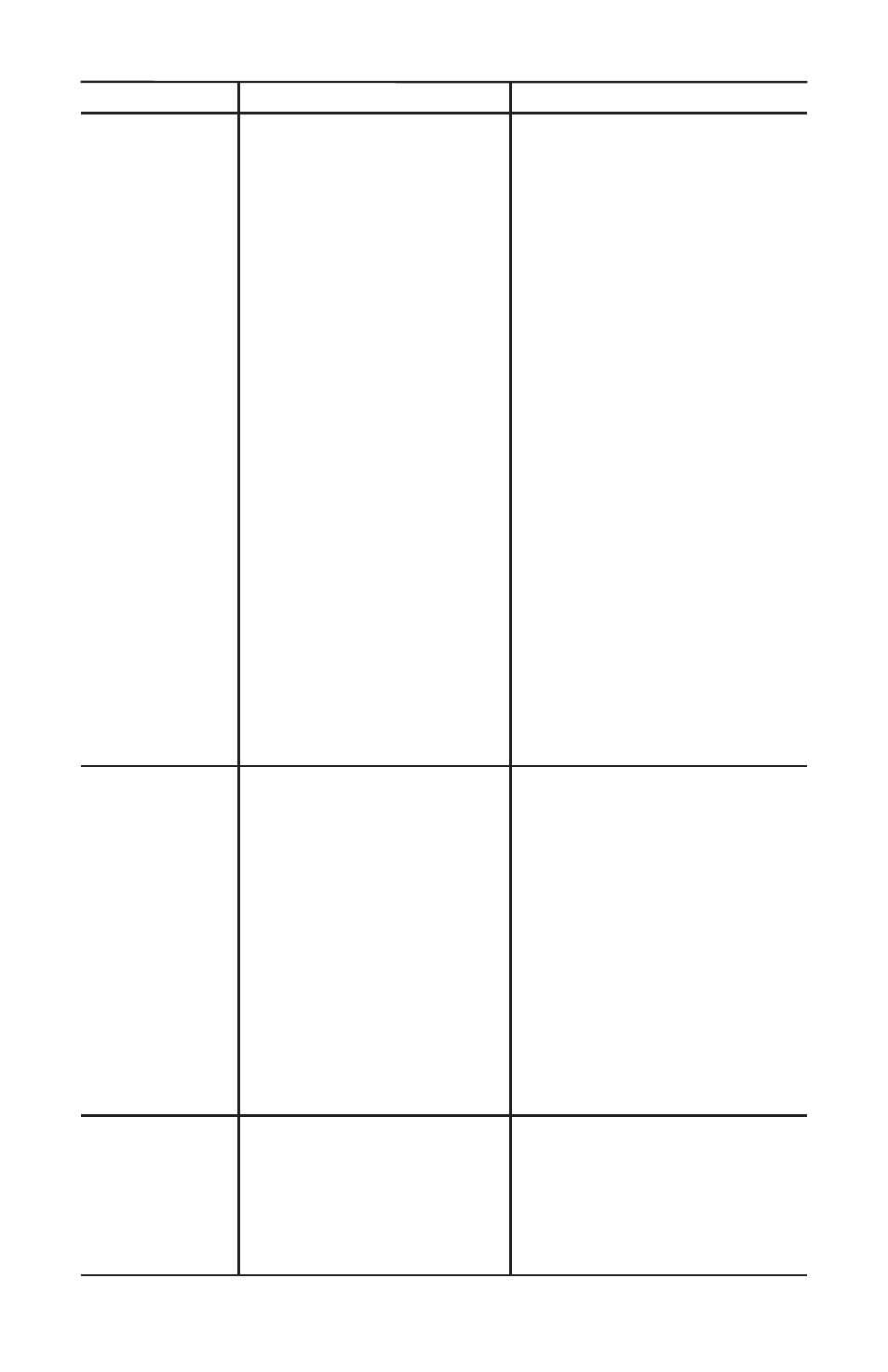

PROBLEM

CAUSE

CORRECTION

Knocking Noise. Possible defect in safety

valve.

Operate safety valve manually

by pulling on ring. If valve still

leaks, it should be replaced.

Loose pulley.

Tighten pulley set screw, see

Parts manual for torque speci-

fications.

Compressor mounting

screws loose.

Tighten mounting screws,see

Parts manual for torque speci-

fications.

Loose flywheel.

Tighten flywheel screw, see

Parts manual for torque speci-

fications.

Loose belt.

Check belt tension, see "Ad-

justing Belt Tension" in the

Maintenance section.

Carbon build-up in pump.

Have checked by a Trained

Service Technician.

Belt to tight.

Check belt tension, see "Ad-

justing Belt Tension" in the

Maintenance section.

Excessive belt

wear.

Loose belt.

Tight belt.

Loose pulley.

Have checked by a Trained

Service Technician.

Pulley misalignment.

See "Motor Pulley/Flywheel

Alignment" paragraph in the

Maintenance section.

Squealing

sound.

Loose belt.

Compressor pump has no

oil.

See Oil-Checking paragraph in

the Maintenance section.

Check belt tension, see "Ad-

justing Belt Tension" in the

Maintenance section.

Check belt tension, see "Ad-

justing Belt Tension" in the

Maintenance section.

Check belt tension, see "Ad-

justing Belt Tension" in the

Maintenance section.

Defective check valve.

Remove and clean, or replace.