Air distribution system, Typical compressed air distribution system – Excell Precision E7540 User Manual

Page 12

12-ENG

A18791

Air Distribution System

Risk of Bursting. Plastic or PVC pipe is not designed for use

with compressed air. Regardless of its indicated pressure

rating, plastic pipe can burst from air pressure. Use only metal pipe for air

distribution lines.

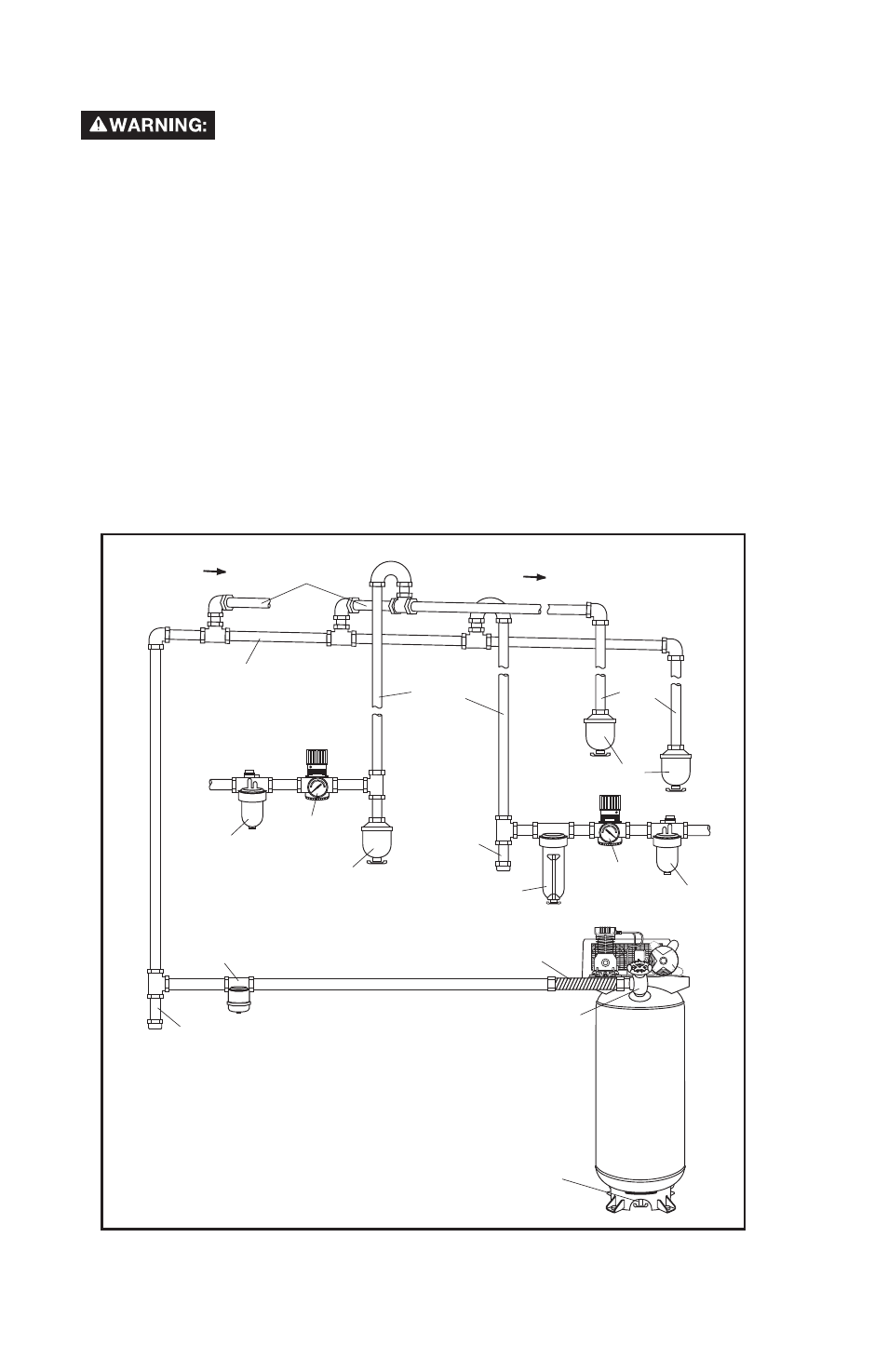

The next figure represents a typical air distribution system. The following are

tips to remember when setting up the air compressor’s air distribution system.

•

Use pipe that is the same size as the air tank outlet. Piping that is too small

will restrict the flow of air.

•

If piping is over 100 feet long, use the next larger size.

•

Bury underground lines below the frost line and avoid pockets where

condensation can gather and freeze. Apply pressure before underground

lines are covered to make sure all pipe joints are free of leaks.

•

A flexible coupling is recommended to be installed between the air

discharge outlet and main air distribution line to allow for vibration.

•

A separate regulator is recommended to control the air pressure. Air

pressure from the tank is usually to high for individual air driven tools.

DRAIN

TRAP

DRAIN

TRAPS

DRAIN

LEGS

MOISTURE

SEPARATOR

AND TRAP

DIRT

LEG

DIRT

LEG

LUBRICATOR

REGULATOR

FILTER

AIR DISCHARGE

VALVE

LUBRICATOR

MAIN DISTRIBUTION AIR LINES

Slope pipe in direction of air flow.

Water condensate flows along

bottom of pipe to drain legs,

preventing it from entering feeder

lines.

REGULATOR

FLEXIBLE

COUPLING

DRAIN COCK

VALVE

TYPICAL COMPRESSED

AIR DISTRIBUTION SYSTEM

AIR FLOW

AIR FLOW

FEEDER LINES SLOPE

WITH AIR FLOW

AIR USAGE

LINES

AIR

COMPRESSOR