Warning – Emerson BP7251 User Manual

Page 10

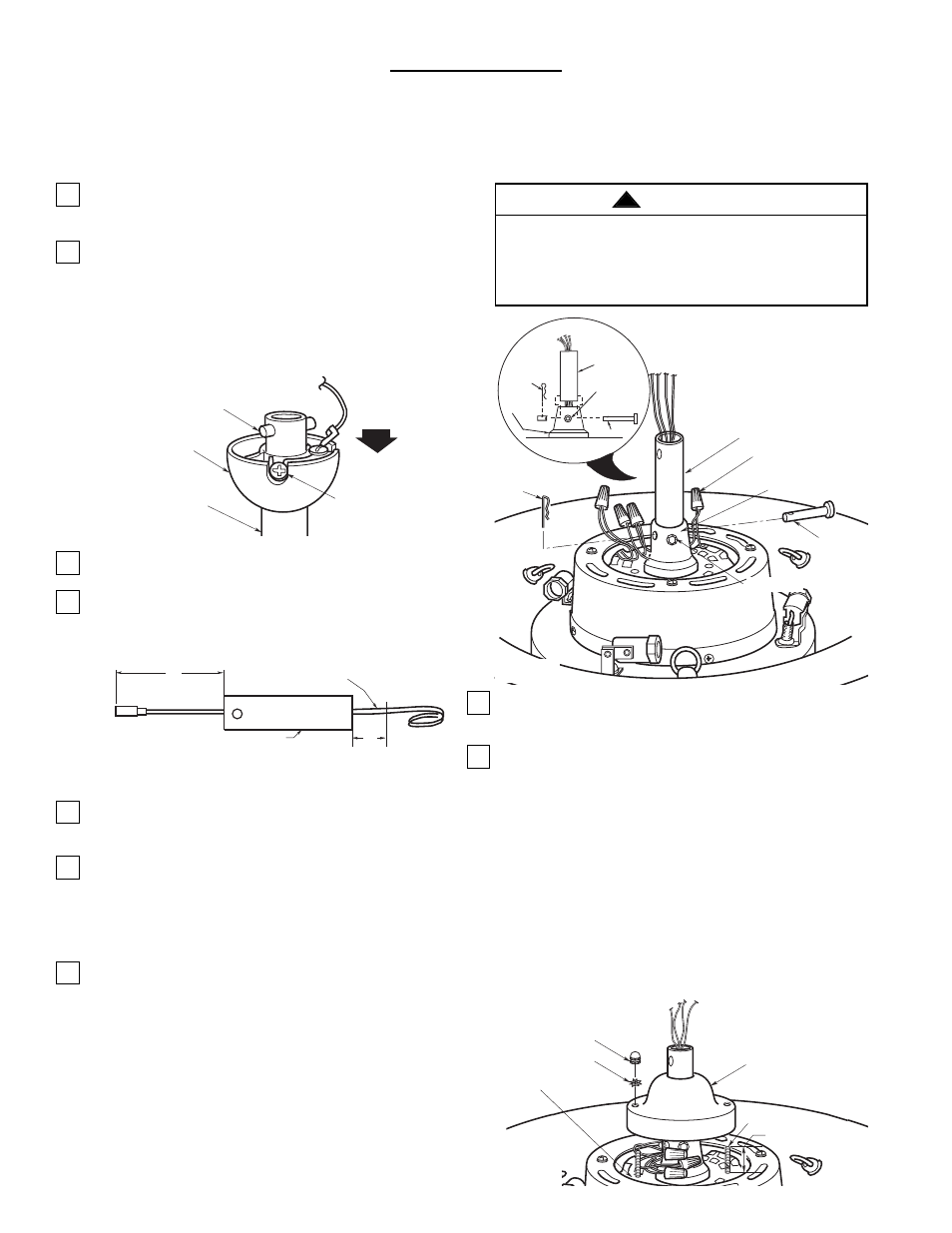

8. Install the setscrew (supplied) in the motor coupling

and tighten using the 5/32” setscrew wrench

(supplied) (Figure 3B).

9. Screw two 1” threaded studs (provided) into the

motor (Figure 4B). Leave approximately 7/8” of the

stud extending above the motor. Coil the wires and

wire connectors around the motor coupling, then

slide the motor cover over the downrod and rotate

the cover until the threaded studs protrude. Install

two lockwashers (supplied) and knurled knobs

(supplied) to secure the cover to the motor. All

wires and wire connectors must be enclosed under

the motor cover.

NOTE: Lightly snug the knurled knob and make

sure the wires and wire connectors are completely

inside the motor coupling cover and not pinched

between the motor coupling cover and the motor.

1. Position the motor housing and shade assembly in

the foam packing so that the top for the motor is

facing you.

2. Obtain the hanger ball/downrod assembly and

remove the hanger ball by loosening the setscrew

in the hanger ball until the ball falls freely down the

downrod (Figure 1B). Remove the pin from the

downrod, then remove the hanger ball. Retain the

pin and hanger ball for reinstallation in Step 9.

Discard 4-1/2” downrod if using 18” or longer

downrod.

3. Push the yellow uplight lead connector through the

downrod (Figure 2B) until it extends about 6”.

4. Cut the yellow lead approximately 3” from the end

of the downrod (Figure 2B). Strip insulation 1/2”

from end of wire.

5. Separate, untwist and unkink the three black, white

and blue motor wires, then route the wires through

the downrod.

6. Using wiring connectors (supplied), connect the

yellow uplight lead to the yellow wire from the

downrod (Figure 3B). Fold the yellow wire into the

slot in the motor coupling, slide the downrod down

the wires and seat the downrod in the motor

coupling.

7. Align the clevis pin holes in the downrod with the

holes in the motor coupling. Install the clevis pin

and secure with the hairpin clip (Figure 3B). The

clevis pin must go through the holes in the motor

coupling and the holes in the downrod. Push the

straight leg of the hairpin clip through the hole near

the end of the clevis pin until the curved portion of

the hairpin clip snaps around the clevis pin. The

hairpin clip must be properly installed to prevent

the clevis pin from working loose.

10

SECTION B

Assembly Instructions for Installing the CF2600 and CF2650

Ceiling Fan Controlled by Emerson Fan/Light Controls

(other than SR330 or SW350) or Standard Wall Switches

HANGER BALL

PIN

DOWNROD

SETSCREW

Figure 1B

7/8"

1" THREADED STUD

MOTOR COVER

KNURLED KNOB

LOCKWASHER

MOTOR

Figure 4B

DOWNROD

MOTOR COUPLING

CLEVIS

PIN

HAIRPIN

CLIP

CONNECT YELLOW

WIRES USING WIRE

CONNECTOR

SETSCREW

SETSCREW

CLEVIS PIN

MOTOR

COUPLING

DOWNROD

HAIRPIN

CLIP

Figure 3B

3"

DOWNROD

CUT HERE

YELLOW UPLIGHT

LEAD

6"

CEILING

END

4-1/2" OR 18"

MOTOR

END

Figure 2B

It is critical that the clevis pin in the motor coupling

is properly installed and the setscrew securely

tightened. Failure to verify that the pin and setscrew

are properly installed could result in the fan falling.

WARNING

!