Page 10 – Echo GT-2000EZR User Manual

Page 25

A

1

D

ESCRIPTION

Page 7

CONTENTS

____ 1 - Trimmer Assembly

____

- Power Head

____

- Drive Shaft Assembly

____ 1 - Plastic Bag (Co-Pack)

____

- Rapid Loader 2-line Head

____

- Operator's Manual

99922203524

12/01

SUP22203524

SUPPLEMENT TO OPERATOR'S MANUAL

PART NUMBER X7702273900 (X770000370)

FOR MODEL: GT-2000EZR S/N 03001001 & UP

Please use this Operator Manual Supplement when

assembling and maintaining your GT-2000EZR.

____

- Safety Manual

____

- Shield Assembly

____

- Hardware Bag

____

-Line Head Mount

____

-1, 3/8-24 Locknut

____

-1, Small Washer

____

-1, Large Washer

____

-12, 8 in. X .080 Pre-cut Nylon Line

____

- Locking Tool

____

- Warranty Card & Limited Warranty

____

- Safety Glasses

____

- Oil 2 Stroke

A

SSEMBLY

- Page 10

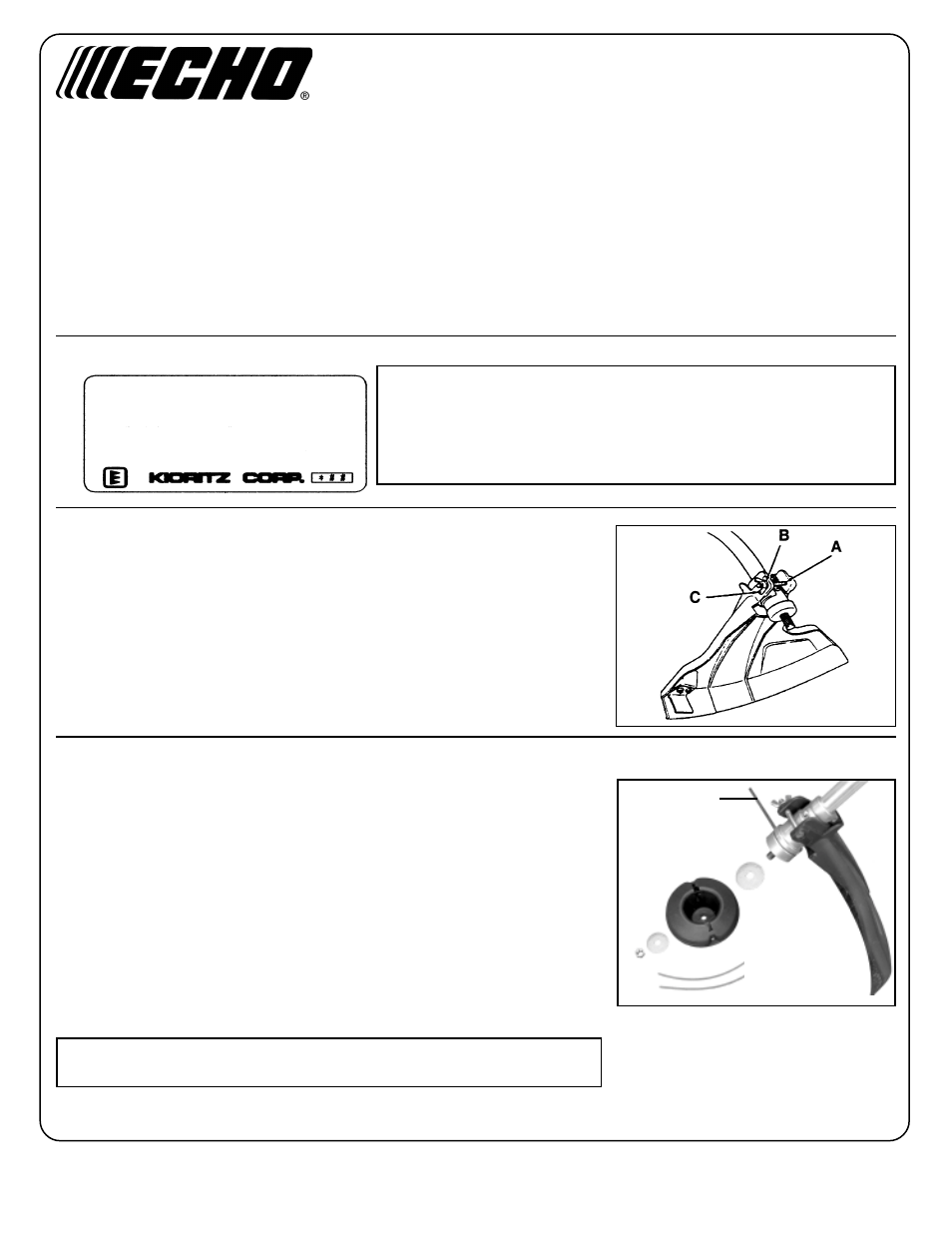

PLASTIC

SHIELD

Tools Required: None

1.

Remove wing nut (C), washer (B), and bolt (A).

2.

Snap the shield over the bearing housing.

3.

Install bolt (A), washer (B) and wing nut (C).

EMISSION

CONTROL

IMPORTANT ENGINE INFORMATION

ENGINE FAMILY : 2EHXS.0214RA DISPLACEMENT : 21.2cc

EMISSION COMPLIANCE PERIOD : 300 HRS.

THIS ENGINE MEETS U.S. EPA PHASE 2 EMISSION

REGULATIONS FOR SMALL NONROAD ENGINES. REFER

TO OWNER'S MANUAL FOR MAINTENANCE SPECIFICA-

TIONS AND ADJUSTMENTS.

PRODUCT EMISSION DURABILITY

The 300 hour emission durability compliance period is the time span selected by

the manufacturer certifying the engine emissions output meets applicable

California and/or U.S. EPA emissions regulations, provided that approved

maintenance procedures are followed as listed in the Maintenance Section of

this manual.

NYLON

LINE

HEAD

Tools Required: Head Locking Tool, 9/16 in. Socket

Parts Required: Rapid Loader

TM

Head.

1.

Remove plastic threaded shaft sleeve from PTO shaft.

2.

Align locating hole in upper plate with hole in bearing housing and insert 1/8 in.

diameter locking tool (A).

3.

Place large washer then line head on threaded shaft followed by small metal washer

and locknut.

4.

Tighten locknut securely.

IMPORTANT

Remember to remove the locking tool.