Initial installation, Never use an open flame for leak testing – Enviro Sonnet C-11253 User Manual

Page 28

28

• A shut-off valve is not supplied with this unit but one should be installed.

• The appliance and its shut-off valves must be disconnected from the gas supply piping system during

any pressure testing where the pressure exceeds 1⁄2 psig (3.45 KPa) or the valve will be damaged.

• The unit must be isolated from the gas supply piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply piping system at pressures equal to or less than

1⁄2 psig (3.45 KPa).

Table 6: Orifice and Pressure Information.

Main Burner

Natural Gas

Propane Gas

Orifice:

#42 DMS

#54 DMS

Manifold Press:

4.0 W.C. (0.99 KPa)

10.0 W.C. (2.47 KPa)

Min. Manifold Press:

0.2 W.C. (0.05 KPa)

2.3 W.C. (0.57 KPa)

Max. Supply Press:

7.0 W.C. (1.74 KPa)

13.0 W.C. (3.28 KPa)

Min. Supply Press:

5.0 W.C. (1.24 KPa)

12.0 W.C. (2.96 KPa)

Max. Input:

26,600 BTU/hr (7.79 KW)

21,300 BTU/hr (6.24 KW)

Min. Input:

6,500 BTU/hr (1.9 KW)

11,400 BTU/hr (3.34 KW)

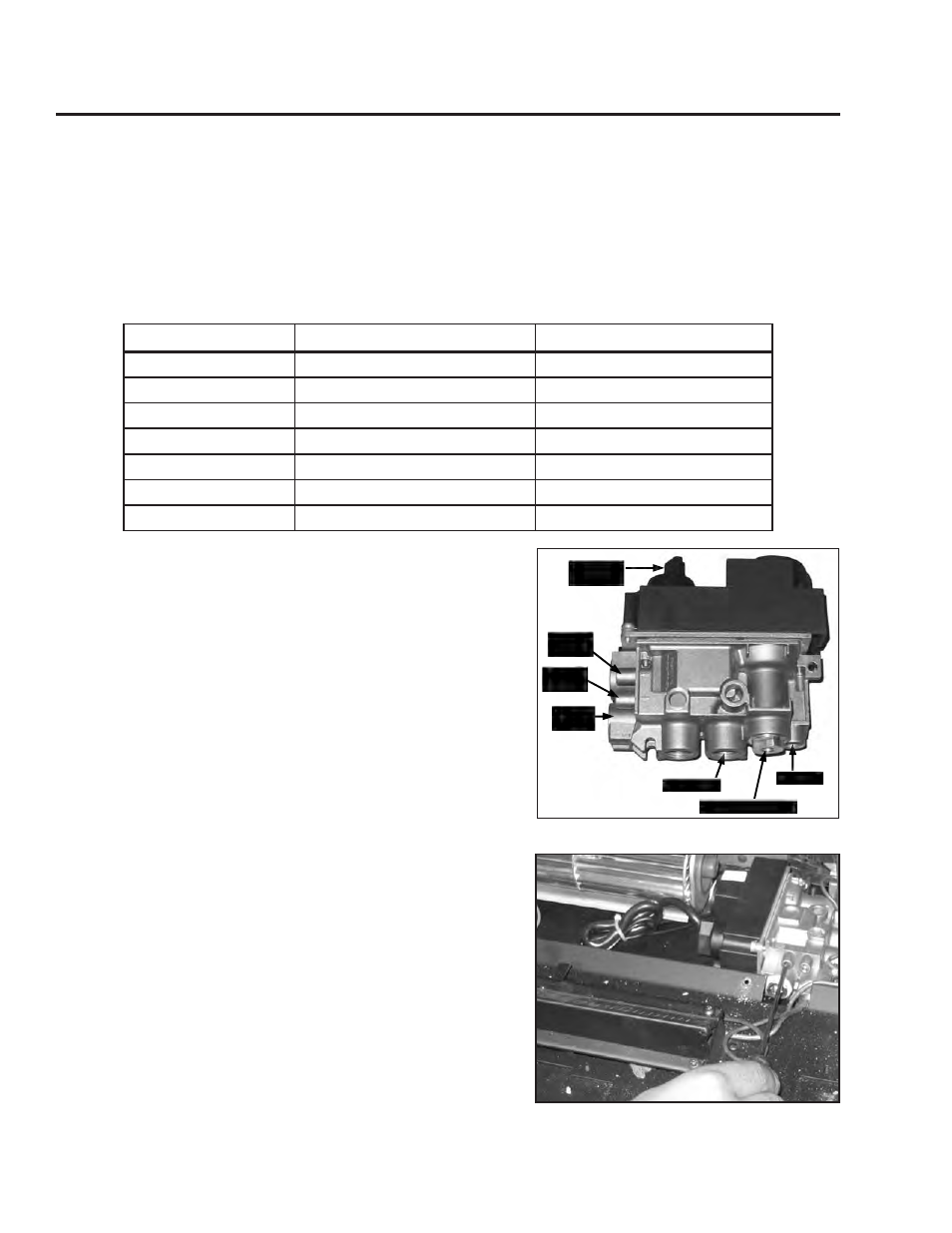

Figure 51: Labeled Gas Valve.

Figure 52: Opening Inlet Pressure Tap on

Valve.

Initial Installation

QUALIFIED INSTALLERS ONLY

TO TEST VALVE PRESSURES:

The pressure taps are located on the front side of the valve

(see Figure 51 & 52).

1. Follow steps 1-4 in R

EMOVING

V

ALVE

C

OVER

- M

AINTENANCE

A

ND

S

ERVICE

. to access the valve.

2. Turn set screw one (1) turn counter-clockwise to loosen.

3. Place

5

/

16

in (8 mm) I.D. hose over the pressure taps.

4. Check pressures using a manometer.

5. When finished, release pressure, remove hose and tighten

set screw.

6. Re-install the valve cover, burner tray, brick panels (refer to

S

ECONDARY

I

NSTALLATION

- I

NSTALLING

THE

B

RICK

P

ANELS

), log

set and ember material (refer to S

ECONDARY

I

NSTALLATION

-

L

OG

S

ET

AND

E

MBER

I

NSTALLATION

) and the glass door.

Always check for gas leaks with a soap and water

solution after completing the required pressure test.

NEVER USE AN OPEN FLAME FOR

LEAK TESTING.