Datamax 200MVP User Manual

Page 13

www.bradyeurope.com

MVP Series Product Guide

- 13 -

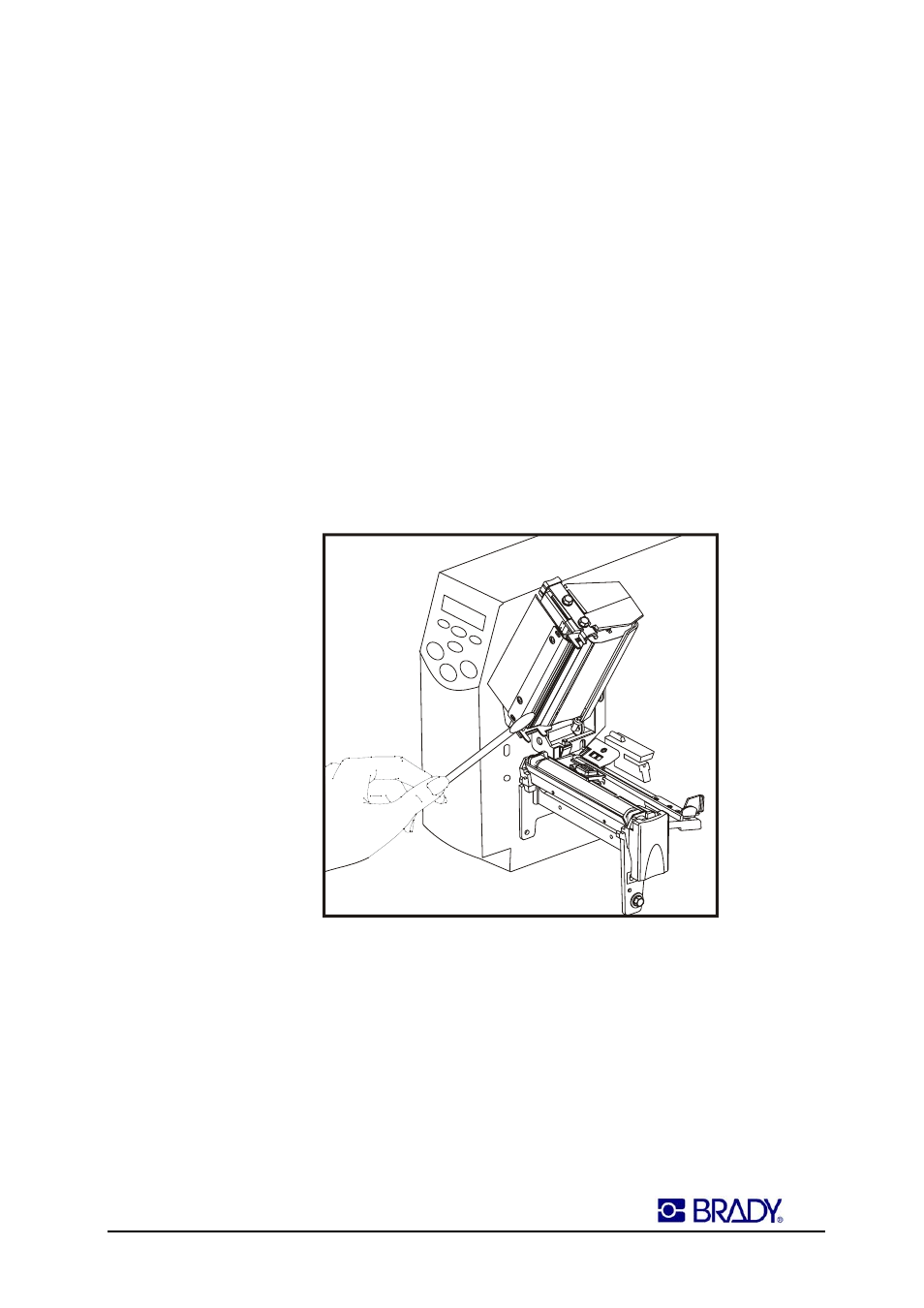

Printer Overview

7. PERIODIC

MAINTENANCE

For optimum performance of the 200MVP or 300MVP thermal printer, Brady

recommends cleaning the printer on a regular basis using standard printer

parts and Brady cleaning supplies. Consult the User’s Guide for specific

details.

•

Cleaning: The exterior is cleaned with a lint-free cloth and if necessary, a

mild detergent solution or desktop cleaner. Interior components –

including the printhead, platen roller, media sensor, peel bar and media

paths – are cleaned with an isopropyl alcohol soaked swab and a vacuum

cleaner or blown air to remove any dirt or dust particles that may have

accumulated during use.

As a general rule of thumb, Brady recommends cleaning the printhead

following ribbon replacement

•

Lubrication: All mechanical parts of the MVP series printers are self-

lubricating and do not require additional lubrication. Hence, less time is

required to maintain the printer promoting increased user productivity.

8. PACKAGING

SPECIFICATIONS

Brady is an ecologically conscious company that strives to manufacture

quality and "environmentally-friendly" products. Our shipping materials,

therefore, are devoid of chemicals (i.e. bleach) and are composed of

biodegradable paper / post consumable and biodegradable glues for easy

recycling. (The packaged shipping weight of a 200MVP or 300MVP is approx.

49 lbs. (22kg)).