Assembly instructions, Assembling tool rests, Assembling spark guards – Delta 23-735 User Manual

Page 6

6

ASSEMBLY INSTRUCTIONS

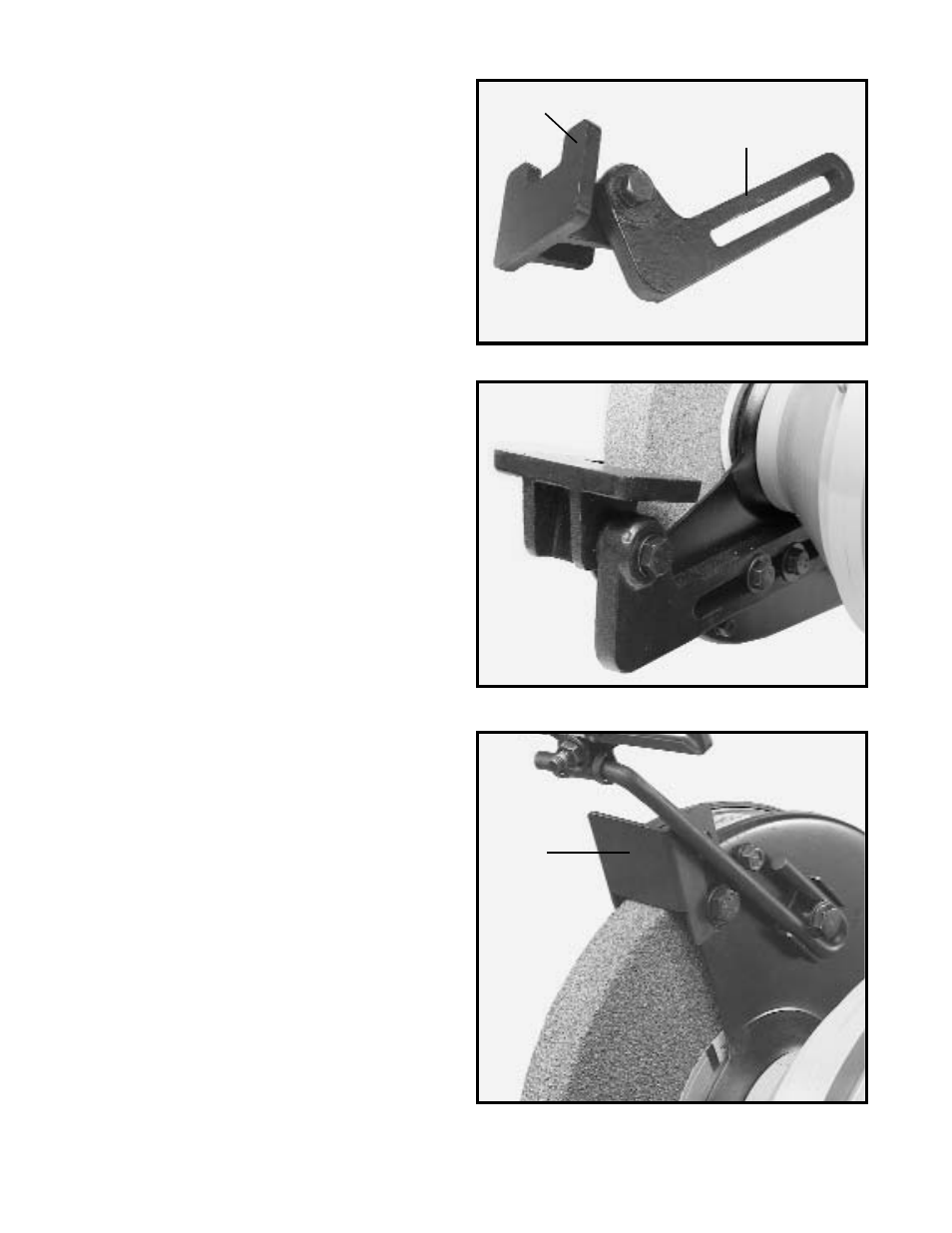

ASSEMBLING TOOL RESTS

1.

The tool rest arms (F) Fig. 3, are universal and can

be attached to either side of the grinder. Assemble

adjustable tool rest (J) Fig. 3, to left side of tool rest arm

(F) Fig. 3, as shown, and fasten with one bolt (1) Fig. 2,

and one washer (7) Fig. 2, as shown. Assemble the

remaining tool rest to the right side of the other tool rest

arm in the same manner. Do not completely tighten

hardware at this time.

2.

To identify the left & right tool rests place them, as

they would be assembled on the tool Fig. 4. The left tool

rest will have a threaded hole on the right side of the tool

rest, and the right tool rest will have a threaded hole on

the left side of the tool rest.

3.

Attach left tool rest assembly Fig. 4, to the inside of

left wheel guard, and fasten with two bolts (2) Fig. 2, and

two washers (7) Fig. 2 as shown.

4.

Attach right tool rest assembly to the inside of right

wheel guard and fasten with two bolts (2) Fig. 2 and two

washers (7) Fig. 2 in the same manner.

5.

Each tool rest assembly Fig. 4, is adjustable so it

can be positioned slightly below the centerline of the

wheel and as close to the grinding wheel as possible,

giving maximum support to the piece that is being

ground. A distance of 1/8-inch or less between the

grinding wheel and the inside edge of the tool rest

should always be maintained.

6.

When the tool rest is positioned correctly, tighten the

hardware. As the grinding wheel wears down to a

smaller diameter, re-adjust the tool rest closer to the

wheel. Freehand grinding without the use of a tool rest

should always be done on the lower quarter of the

wheel.

ASSEMBLING SPARK GUARDS

The spark guard (I) Fig. 5, is to be mounted to the side

of each wheel guard, using one bolt (4) Fig. 2, and one

washer (8) Fig. 2 as shown. The spark guard (I) should be

adjusted as close as possible to the grinding wheel so

that sparks never strike the operator’s hand. As the

wheels wear down, the spark guard (I) should be

adjusted accordingly.

Fig. 3

J

F

Fig. 4

Fig. 5

I