Adjusting the table positive stops, Adjusting belt tension – Delta ShopMaster SM400 User Manual

Page 15

15

ADJUSTING THE TABLE

POSITIVE STOPS

Positive stops are provided for the table at the 90 and 45

degree angle to the blade. To check and adjust the

positive stops, proceed as follows:

DISCONNECT MACHINE FROM POWER

SOURCE.

1.

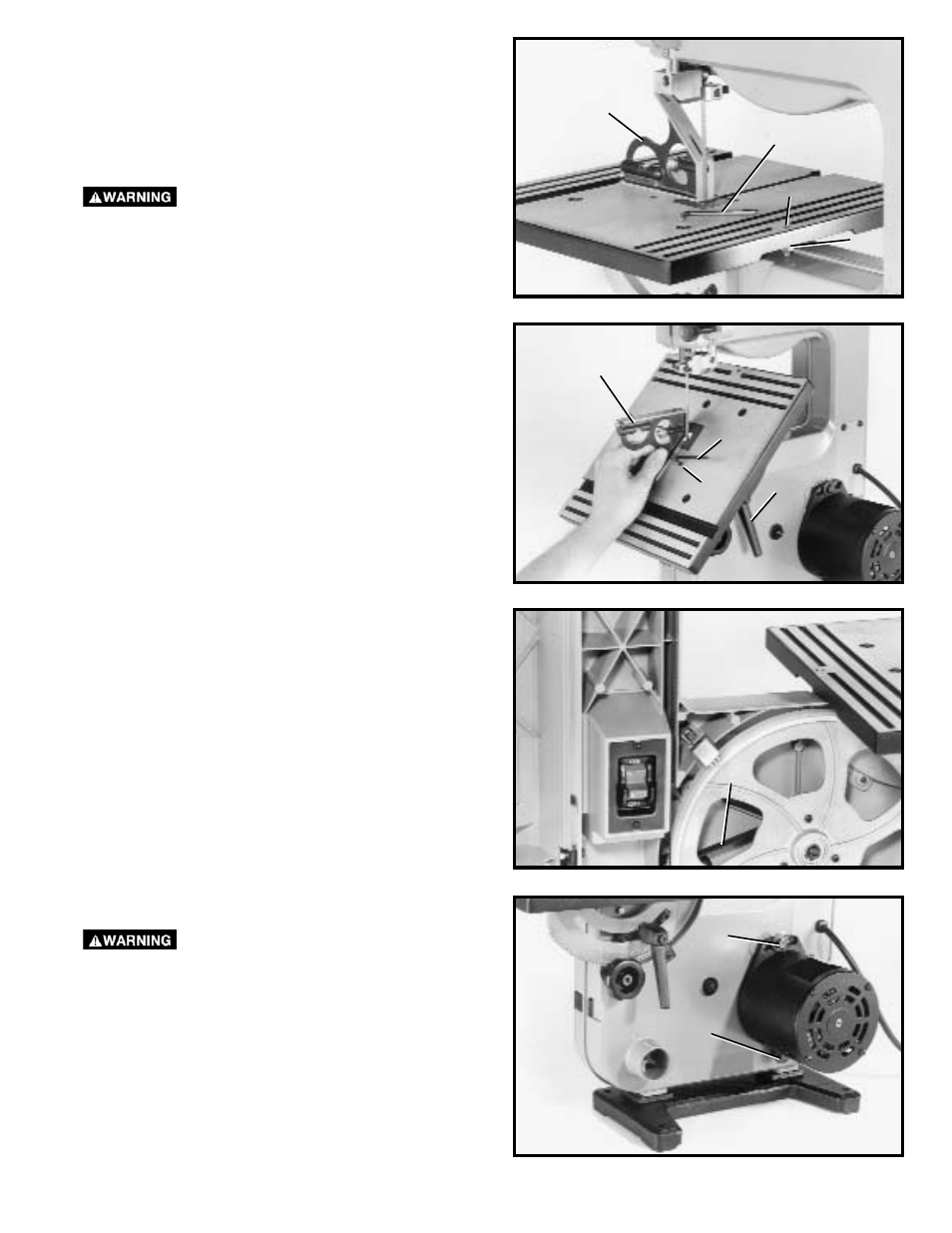

Tilt the table to the 90 degree position as shown in

Fig. 27, and tighten lock handle (A) Fig. 28. Place a

square (H) Fig. 27, on the table and against the blade

and check to see if the blade is 90 degrees to the table

surface. If an adjustment is necessary, proceed as

follows:

2.

Tilt the table slightly as shown in Fig. 26, to expose

lock nut (E) Fig. 27. Loosen lock nut and return table to

the 90° position. With the lock handle (A) Fig. 28 loose,

turn adjusting screw (F) Fig. 27, using the wrench (G)

provided until the blade is 90 degrees to the table. Then

tighten lock nut (E) Fig. 27, and lock handle (A) Fig. 28.

3.

Tilt the table to the 45 degree position as shown in

Fig. 28. Place a square (H) on the table and against the

blade and check to see if the blade is 45 degrees to the

table surface. If an adjustment is necessary, proceed as

follows:

4.

Loosen lock nut on adjustment screw (J) Fig. 28,

located on the underside of the table. With lock handle

(A) Fig. 28 loose, turn adjustment screw (J) using wrench

(G) provided until the blade is 45 degrees to the table.

Then tighten lock handle (A), and lock nut on adjustment

screw (J).

Fig. 28

H

J

G

A

Fig. 27

H

F

G

E

Fig. 29

A

B

B

ADJUSTING BELT TENSION

If the drive belt on your band saw needs adjustment,

proceed as follows:

DISCONNECT MACHINE FROM POWER

SOURCE.

The belt (A) Fig. 29, drives the blade wheel pulley from

the motor pulley. The belt (A) is properly tensioned when

there is approximately 1/4" deflection in the center span

of the belt using light finger pressure. If belt tension

needs to be adjusted, loosen two screws (B) Fig. 30, and

rotate motor accordingly. Tighten screws (B) when

adjustment is completed.

Fig. 30