Delta BS150LS User Manual

Page 14

14

14

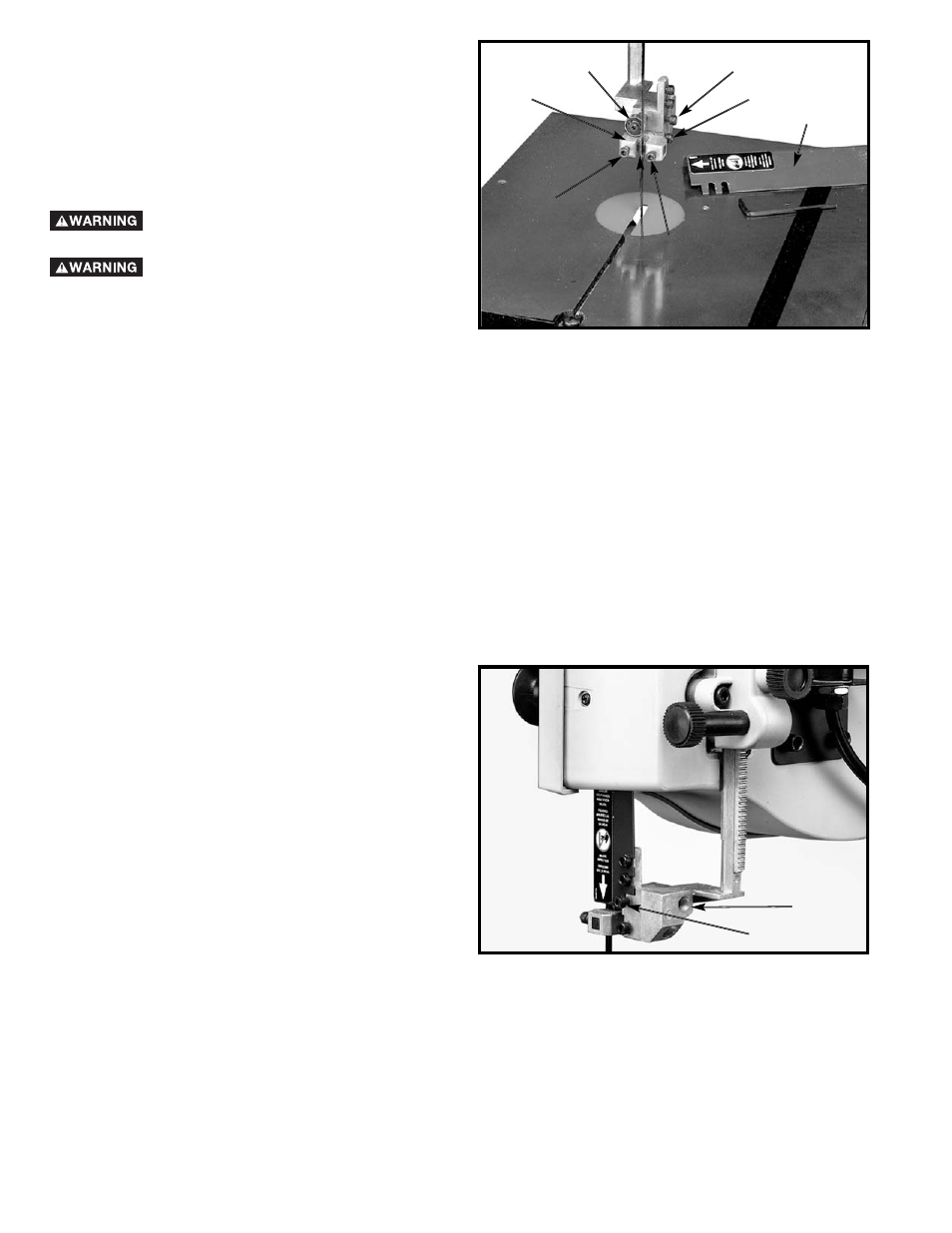

ADJUSTING UPPER BLADE

GUIDES AND BLADE SUPPORT

BEARING

I M P O RTA N T: B O T H T H E U P P E R A N D L O W E R

BLADE GUIDES MUST BE PROPERLY ADJUSTED

TO PREVENT THE BLADE FROM TWISTING DURING

OPERATION.

DISCONNECT MACHINE FROM POWER

SOURCE.

UPPER BLADE GUARD (B) FIG. 27 IS

SHOWN REMOVED FOR CLARITY. ALWAYS MAKE

SURE THE UPPER BLADE GUARD IS INSTALLED AND

PROPERLY ADJUSTED BEFORE OPERATING THE

BAND SAW.

1.

Loosen the two screws (C) Fig. 27, and adjust the

blade guides (D) as close as possible to the sides of the

saw blade, being careful not to pinch the blade. Tighten

the two screws (C).

2.

Loosen screw (E) Fig. 27, and move the guide

bracket (F) in or out until the front edge of the guides (D)

are just behind the “gullets” of the blade teeth. Tighten

screw (E).

3.

The upper blade support thrust bearing (G) Fig. 27

prevents the saw blade from being pushed back too far

when cutting. The support bearing (G) should be

adjusted approximately 1/32" behind the blade. The

blade should also overlap the outside diameter of the

ball bearing by approximately 1/8". To adjust:

4.

Loosen screw (H) Fig. 28, and slide support bearing

(G) in or out until it is approximately 1/32" behind the

saw blade.

5.

The upper blade support bearing (G) Fig. 27, is set

on an eccentric shaft. To change position of bearing (G),

use a straight screwdriver, rotate shaft (J) Fig. 28, until

the blade properly overlaps the support bearing. Then

tighten screw (H).

Fig. 27

Fig. 28

G

F

H

E

C

C

D

B

J

H