Machine use – Delta 20-950 User Manual

Page 15

15

NOTE: Use drill bits with shank diameters of 5/8" or less.

NOTE: After installing a drill bit, use the supplied key to tighten all three locations on the chuck.

The use of accessories and attachments not recommended by Delta may result in risk of injury.

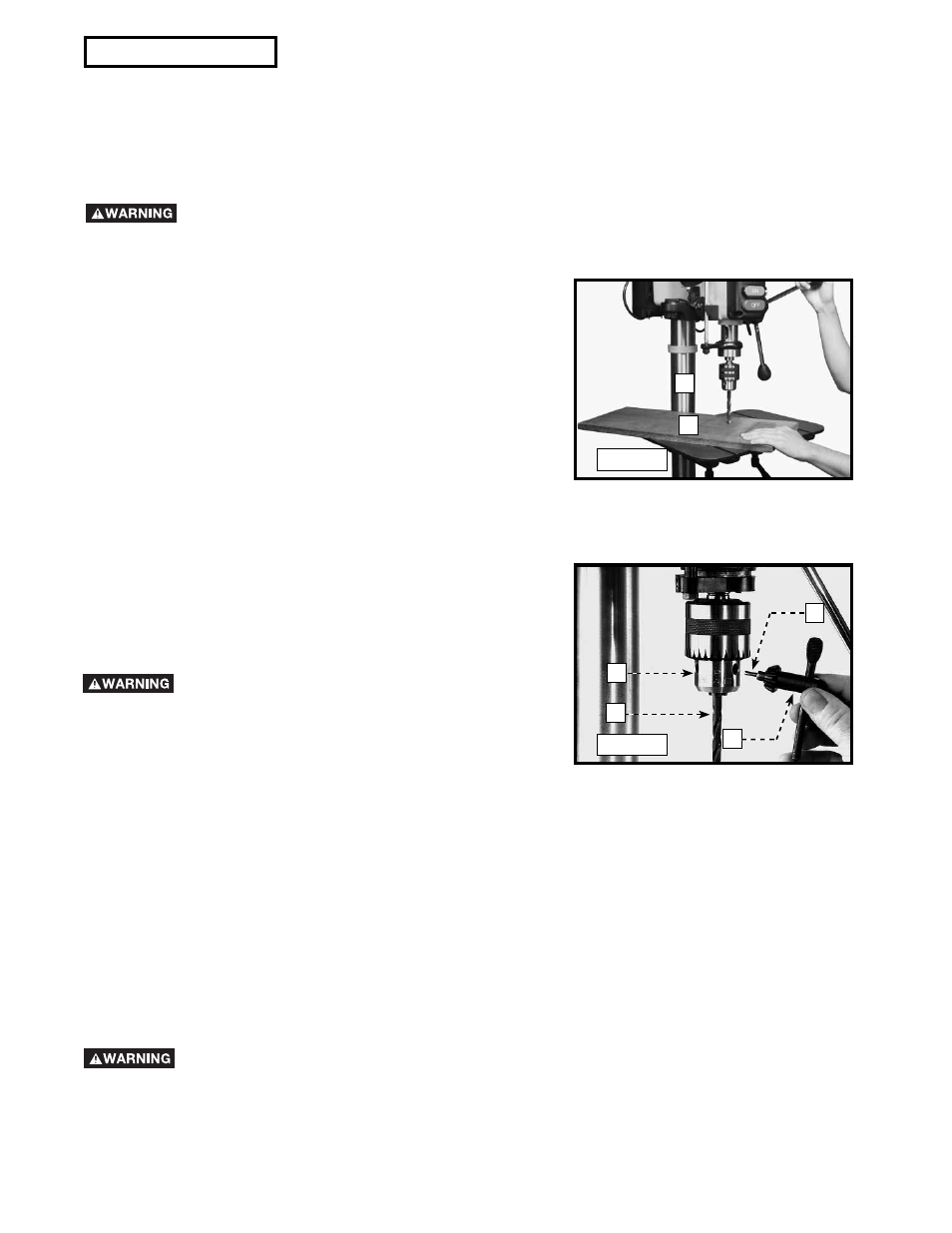

IMPORTANT: When the workpiece (A) Fig. 44 is long

enough, position it on the table with one end against the

left side of the column (B) to prevent the workpiece from

rotating. If it is not possible to support the workpiece

against the column, clamp the workpiece to the table.

Fig. 44

A

B

MACHINE USE

Fig. 45

A

B

D

C

NOTE: Use drill bits with a shank of 5/8" or less in diameter.

DISCONNECT THE MACHINE FROM THE

POWER SOURCE

!

1. Insert the smooth end of drill bit (A) Fig. 45 in the chuck (B) as far as it will go, and then back the bit out 1/16" (or

up to the flutes for small bits).

2. Center the drill bit (A) Fig. 45 in the chuck (B) before tightening the chuck with the key (C).

3. Turn the chuck key (C) Fig. 45 clockwise to tighten and counter-clockwise to loosen the chuck jaws.

4. Tighten all three chuck jaws to secure the drill bit sufficiently to prevent slipping.

5. Remove the chuck key (C) Fig. 45 from the chuck before starting the drill press. The chuck key (C) is equipped with

a self-ejecting pin (D) which helps minimize the potential for the key to be left in the chuck.

INSTALLING AND REMOVING DRILL BITS

CORRECT DRILLING SPEEDS

Factors that determine the correct speed are 1) the workpiece, 2) the size of the hole, 3) the type of bit or other cutter,

and 4) the quality of cut.

Use the recommended speed for the the drill press bit and workpiece.