Operation, Operational controls and adjustments – Delta 20-950 User Manual

Page 12

12

OPERATIONAL CONTROLS AND ADJUSTMENTS

OPERATION

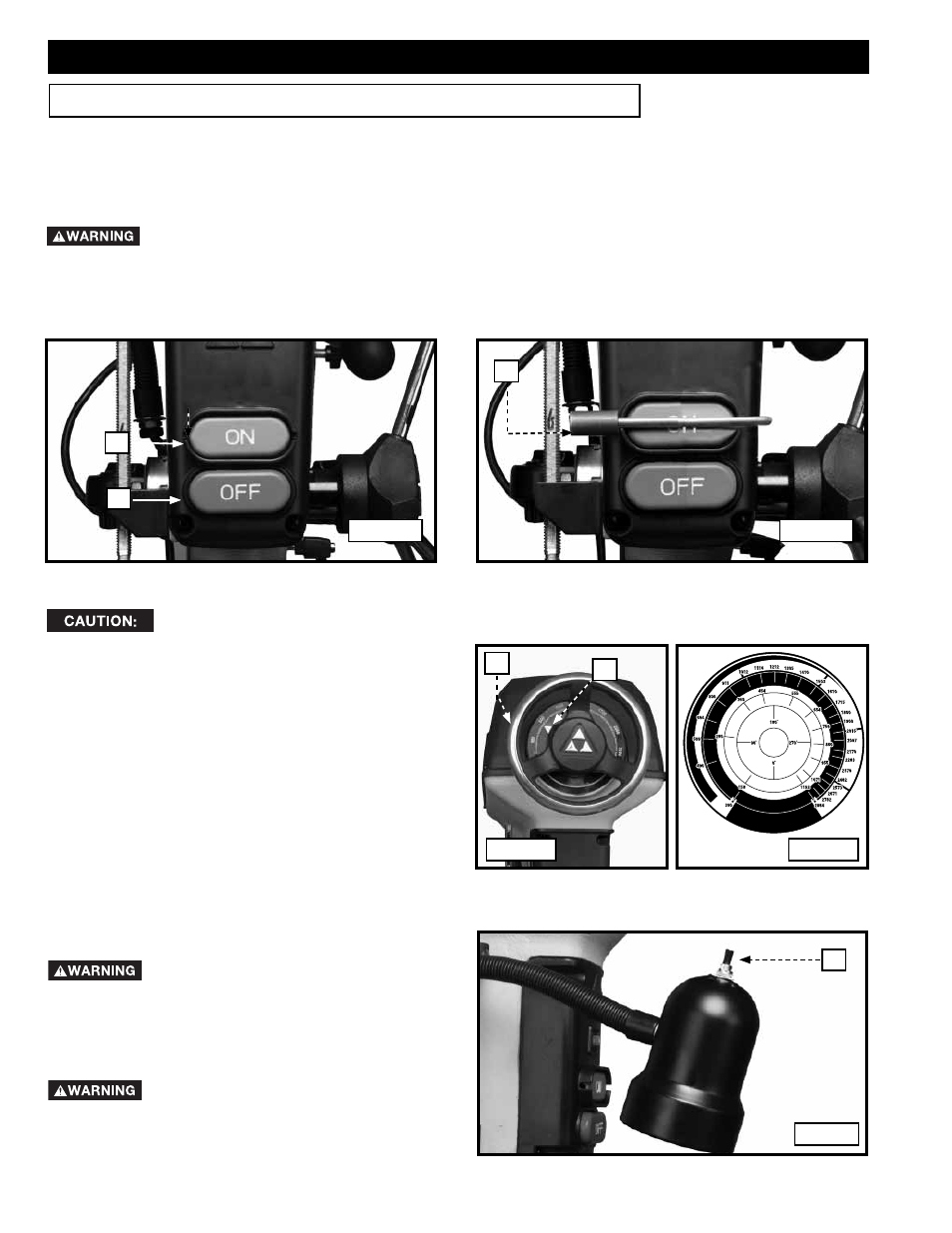

1. The on/off switches (A and B) Fig. 24A are located on the front of the drill press. To turn the machine “ON”, depress

the “ON” switch.

2. To turn the machine “OFF”, depress the “OFF” switch.

Make sure that the switch is in the “OFF” position before plugging in the power cord. In the event of a

power failure, depress the “OFF” switch. An accidental start-up can cause injury.

STARTING AND STOPPING THE DRILL PRESS

A

B

A

Fig. 24A

Fig. 24B

IMPORTANT: When the machine is not in use, lock the switch

in the "OFF" position to prevent unauthorized use,

using a

padlock (A) Fig. 24B with a 3/16" diameter shackle.

FIRE HAZARD. To reduce the risk of

fire, use a 40 watt or less, 120 volt, reflector track-

type light bulb (not supplied). DO NOT USE a stan-

dard house hold light bulb. Do not allow the reflector

track-type light bulb to extend below the lamp

shade.

RISK OF PERSONAL INJURY.

Disconnect the machine from the power source

before making any adjustments.

A

FLEXIBLE LAMP

The flexible lamp op er ates in de pen dent ly of the drill press. To turn the lamp “ON” and “OFF”, rotate switch (A) Fig.

26.

Fig. 26

SPINDLE SPEED ADJUSTMENT

Adjust the spindle speed ONLY when the machine is in operation.

1. Determine the proper speed for your cutting tool (bits,

drums, etc.)

2. Press the "ON" button to power the machine.

3. Use both hands to turn the speed-adjusting wheel

(A) Fig. 25A until the pointer (B) indicates the correct

speed.

4. Fig. 25B illustrates the speeds.

A

B

Fig. 25A

Fig. 25B