Machine use, Adjusting the spindle return spring – Delta 17-990X User Manual

Page 15

15

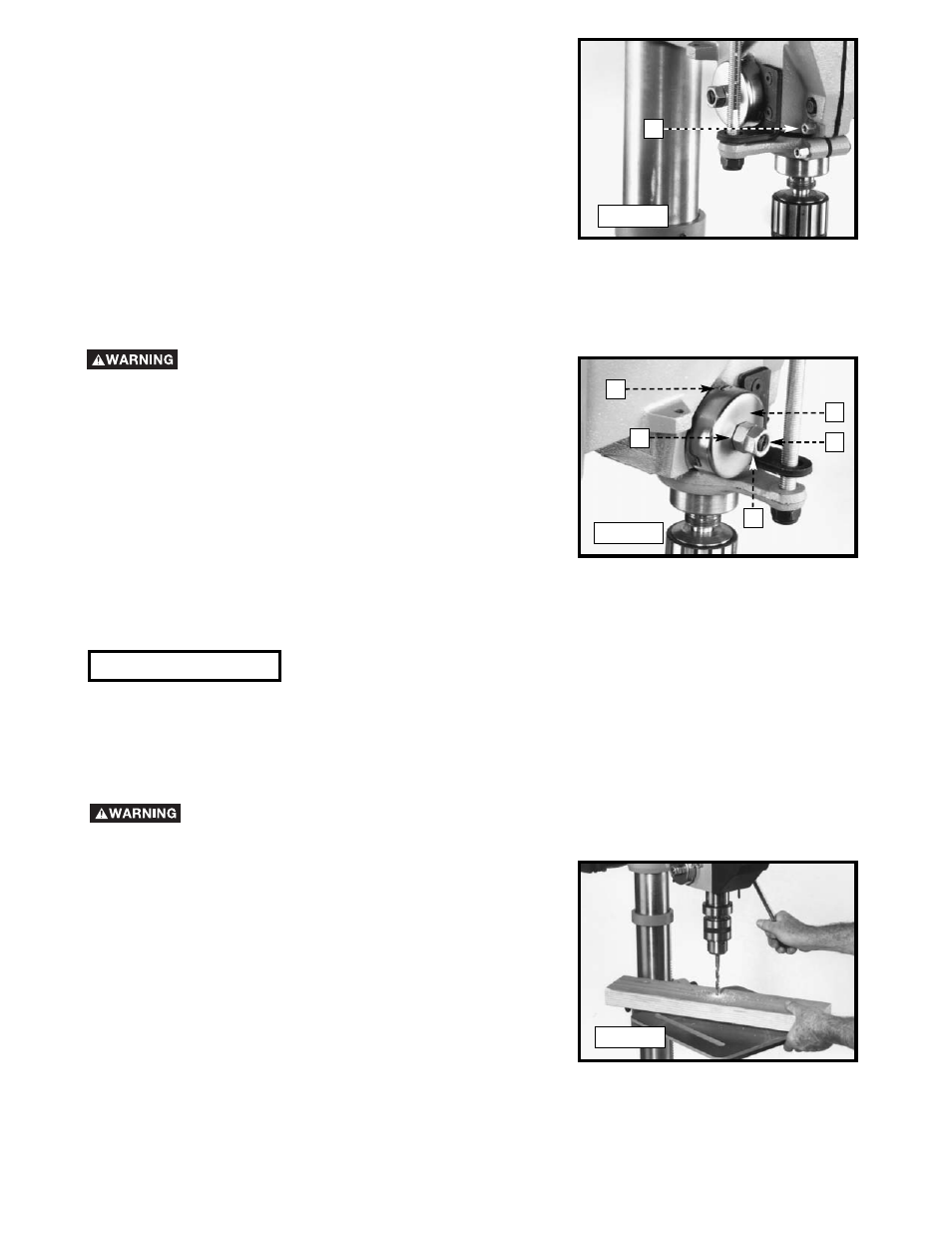

ADJUSTING THE SPINDLE RETURN SPRING

The spindle will automatically return slowly to its upper position when the handle is released. The spindle return spring

was properly adjusted at the factory. However, to adjust, if necessary:

1.

Loosen the nuts (B) and (E) Fig. 37, but do not remove. Make

sure that the spring housing (A) remains engaged with head

casting (C).

2.

While firmly holding the spring housing (A) Fig. 37, pull out

the housing and rotate it (counter-clockwise to increase or

clockwise to decrease the spring tension) until the boss (D)

is engaged with the next notch on the housing. Tighten the

two nuts (B) Fig. 37 to hold the housing in place.

IMPORTANT: The inside nut (B) should not contact spring housing (A) when tightened.

DISCONNECT MACHINE FROM POWER SOURCE.

The sliding fit of the quill was adjusted at the factory. After a

long period of time, “play” between the quill and head

casting may develop. To re-adjust, loosen the nut (F) Fig. 36

and tighten the screw (E) Fig. 35 with the supplied hex

wrench. After adjustment, hold the screw (E) Fig. 36, and

tighten the nut (F) Fig. 36. Check the sliding fit by moving the

quill up and down several times to be sure the quill does not

bind.

Fig. 36

F

NOTE: Use drill bits with shank diameters of 1/2" or less.

NOTE: After installing a drill bit, use the supplied key to tighten all three locations on the chuck.

The use of accessories and attachments not recommended by Delta may result in risk of injury.

IMPORTANT: When the workpiece (B) Fig. 38 is long enough,

position it on the table with one end against the left side of the

column (C) to prevent the workpiece from rotating. If it is not

possible to support the workpiece against the column, clamp the

workpiece to the table.

MACHINE USE

Fig. 37

Fig. 38

D

A

C

B

E