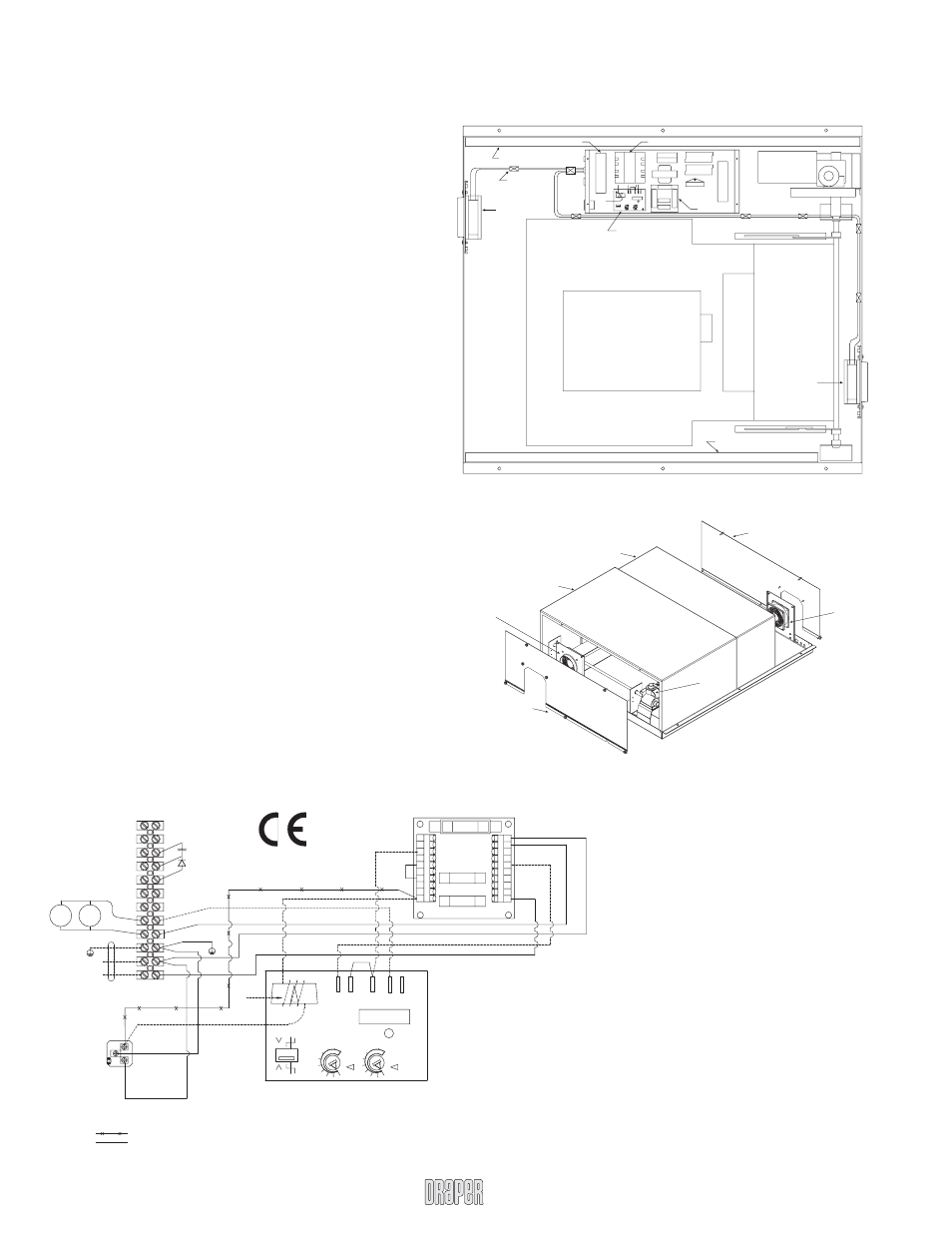

Field installation of plenum kit, Figure #1 diagram #1 figure #2, Cs 1 – Draper Video Projector User Manual

Page 6

220 V Revelation by DRAPER

Page 6 of 8

Field Installation of Plenum Kit

Caution! Disconnect power from the Revelation before installing ple-

num.

➀ Remove the covers from the electrical chassis in the Revelation.

➁ Disconnect the black 14 awg. wire that runs from the T2 trans form er to

the re cep ta cle in the electrical chassis.

➂ Install the pre-wired current sensor using two #6-32 x 1" [10] long screws

provided. (SEE FIGURE #1.)

➃ Connect each wire of the pre-wired current sensor as shown by DIA-

GRAM #1.

➄ Install the two fan mount assemblies [5,6] to the main pan of the Rev e -

la tion using the eight #10-32 x .

3

/

8

" [7,8] long screws provided. (SEE

FIGURE #1.) Attach the long leads of the Exhaust Fan As sem bly [6] to

the end with the motor and lifting mechanism.

➅ Using the wire clips [11] provided, lay in the wires from the fans as

shown in FIG URE #1 and con nect the fans to TB1-8 & TB1-9 as shown

in DI A GRAM #1.

➆ Replace the covers to the electrical chassis.

➇ Apply the 25 mm wide Nylon [12,13] tape as shown in FIGURE #1.

➈ Install the inner and outer plenum covers [1,2], and attach the mating

end panel [3,4] as shown in FIGURE #2.

➉ Fan mounting panels are designed to accept a standard 4" round duct.

The exhaust fl ange is located on the motor/drive end of the Rev e la tion

and the input is located at projector end of the Revelation.

If duct work is connected to this unit, here are a few recommended guide lines

you should keep in mind when installing the duct work:

• Air supply to the plenum should be cool enough to provide adequate cool-

ing for your projector.

• Do not obstruct airfl ow through duct work. Inadequate airfl ow may result in

excessive heat buildup inside the unit.

• Keep duct work length as short as possible. Recommended maximum total

duct length is 914 cm (input plus ex haust).

• Keep the input-to-exhaust length ratio balanced and as small as possible

to prevent air from being pushed into or drawn out of the room.

FIGURE #1

DIAGRAM #1

FIGURE #2

PLENUM INSTALLATION PART LIST

ITEM# DESCRIPTION

QTY

1

INNER PLENUM COVER

1

2

OUTER PLENUM COVER

1

3

INNER END PANEL

1

4

OUTER END PANEL

1

5

INPUT FAN MOUNT ASSEMBLY

1

6

EXHAUST FAN MOUNT ASSEMBLY

1

7

SCREW #10–32 X .375" (9.525mm)

8

HEX HD TYPE "F" ZINC

8

WASHER, #10 ZINC INTERNAL LOCK

8

9

PRE-WIRED CURRENT SENSOR

1

10 SCREW #6–32 X 1" (25.4mm)

2

LONG PHIL PAN HD ZINC

11 CLIP ADHESIVE BACKED CORD

7

6.35mm HOLD ING DIA.

12 991 mm LONG 25.4mm WIDE X .762mm

1

THICK NYLON TAPE

13 1092mm LONG 25.4mm WIDE X .762mm

1

THICK NYLON TAPE

TOOLS NEEDED

MED POINT PHILLIP SCREWDRIVER

1

/

8

" FLAT BLADE SCREW DRIVER

3

/

8

" WRENCH

Nylon tape 43" long

Wire clips typ.

Input

fan

assembly

(short

wires)

Curent sensor

TB1

T2

F4

F5

F1

F3

F2

T1

C1

CR2

CR1

TB2

CS1

1 12

1 12

1 2 3 4 5

BK

BK

WH

BK RD

1 10

1 10

CB1B

CB1A

PCB1

PCB1

Nylon tape 39" long

Projector

Exhaust

fan

assembly

(long

wires)

T2 transformer

F1 = 7 Ampere

F2 = 1 Ampere

F3 = 1 Ampere

F4 = 4 Ampere

F5 = 4 Ampere

TB1

Outer Plenum cover

Inner Plenum cover

Inner end panel

Outer end panel

Exhaust

fan

assembly

Input

fan

assembly

Motor

WIRE TO BE REMOVED BEFORE INSTALLING PLENUM WIRING

3. ALL WIRES 18 AWG. UNLESS OTHERWISE SPECIFIED.

WIRES CONNECTED BY INSTALLER

2.

NOTES:

1.

14 AWG

4 TURNS

CS 1

I

I

t

1 2

I

3

4 5

PCB 1

WH

BK

CB1B

RD

BK

BK

BK

10

9

7

8

6

BK

35

4

2

1

F2

F1

F3

CB1A

8

10

9

7

6

BK

3

4

52

1

BK

(IN)

FAN

FAN

(OUT)

BK

YW/GN

7

10

9

8

RD

BE

46

5

3

12

D1

C2

TB 1

220 VAC SUPPLY

L1

N

12

11

RD

50 - 60 HZ

PROJECTOR

OUTLET

BE

14 AWG

RD

YW/GN

14 AWG

14 AWG

BE

BE

BE

BE

BE

www.draperinc.com

(765) 987-7999