Appendix e: error codes & troubleshooting, Sensor replacement requires calibration gas – Test Products International 708 User Manual

Page 29

Appendix E: ERROR CODES & TROUBLESHOOTING

The 708 analyzer will display certain codes to let you know of a malfunction.

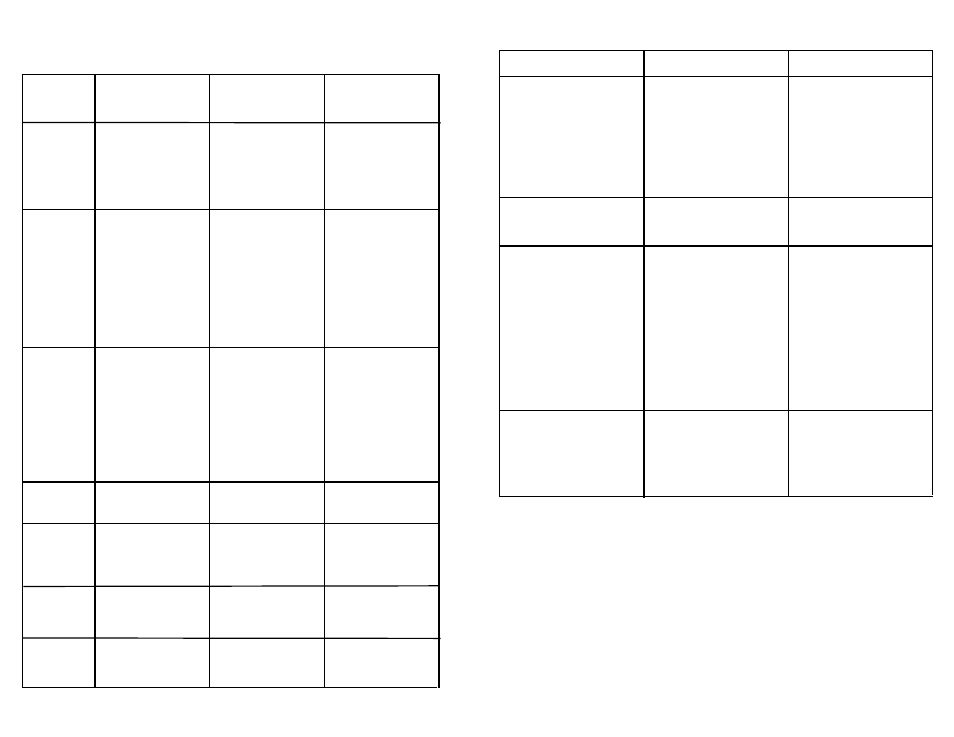

Code

Displayed

Code Definition

Possible Causes

Corrective Action

Flo

Err

Pump not drawing sample at

correct flow rate.

Blockage / kink in flue probe

hose.

Dirty or blocked filter(s).

Worn pump.

Check and rectify.

Replace filter(s).

Return to TPI for service.

InIt

O2

Err

Oxygen sensor failed to ini-

tialize

Flue probe connected to 708

prior to power up.

708 did not purge completely

from last sample.

Worn or defective oxygen

sensor.

Disconnect probe and

restart.

Purge for 20 minutes and

restart.

Return to TPI for sensor

replacement or install new

sensor.*

Try manually initializing the

sensor. See Appendix G.

InIt

CO

Err

Carbon monoxide sensor

failed to initialize.

Flue probe connected to 708

prior to power up.

708 did not purge completely

from last sample.

Worn or defective carbon

monoxide sensor.

Disconnect probe and

restart.

Purge for 20 minutes and

restart.

Return to TPI for sensor

replacement or install new

sensor.*

Try manually initializing the

sensor. See Appendix G.

Lo

bat

Low battery.

Battery needs to be charged. Charge battery. If the battery

won’t hold a charge, replace

the battery.

oFL

Overflow indication. The car-

bon monoxide being

mesured is above the instru-

ments capability.

CO being measured is too

high or low.

Remove the CO source and

allow the 708 to purge.

oFL

Overflow indication. The tem-

perature being measured is

outside the maximum mea-

surement capability.

Temperature being measured

is too high or low.

Remove pressure source.

oPEn

Unable to read thermocouple

(temperature).

Temperature probe not con-

nected to input.

Worn temperature sensor.

Connect temperature probe

to analyzer.

Replace temperature probe

or flue probe.

*Sensor replacement requires calibration gas.

Appendix E: ERROR CODES & TROUBLESHOOTING (Continued)

Problem

Possible Cause

Corrective Action

Efficiency reading incorrect

NET efficiency selected.

Ambient temperature probe

not plugged in to T2.

Incorrect fuel selected.

Select GROSS efficiency.

See section 5.3.

Plug ambient probe into T2.

See section 5.2.

Select the proper fuel for the

equipment being tested. See

section 4.1.

Readings are erratic when

working on oil fired equip-

ment.

Oil filter not installed or

installed incorrectly.

Make sure the optional oil fil-

ter (A773) is installed. See

Appendix D.

One or all of the following

parameters; Ratio, CO air

free, excess air, and efficien-

cy read and print dashes.

Measured values are such

that the calculated values of

these parameters are out of

range.

Redo combustion test. Since

these are calculated values,

the measure values must be

within certain levels for these

to display. If the measured

oxygen level is above 19.9%

these parameters won’t

read.

These parameters might not

display or be applicable in

some tests.

Analyzer won’t turn off

Oxygen and/or carbon

monoxide levels outside lim-

its.

Allow the analyzer to purge

longer.