Mounting plastic base models – Star Headlight & Lantern 400A-LED User Manual

Page 3

-2-

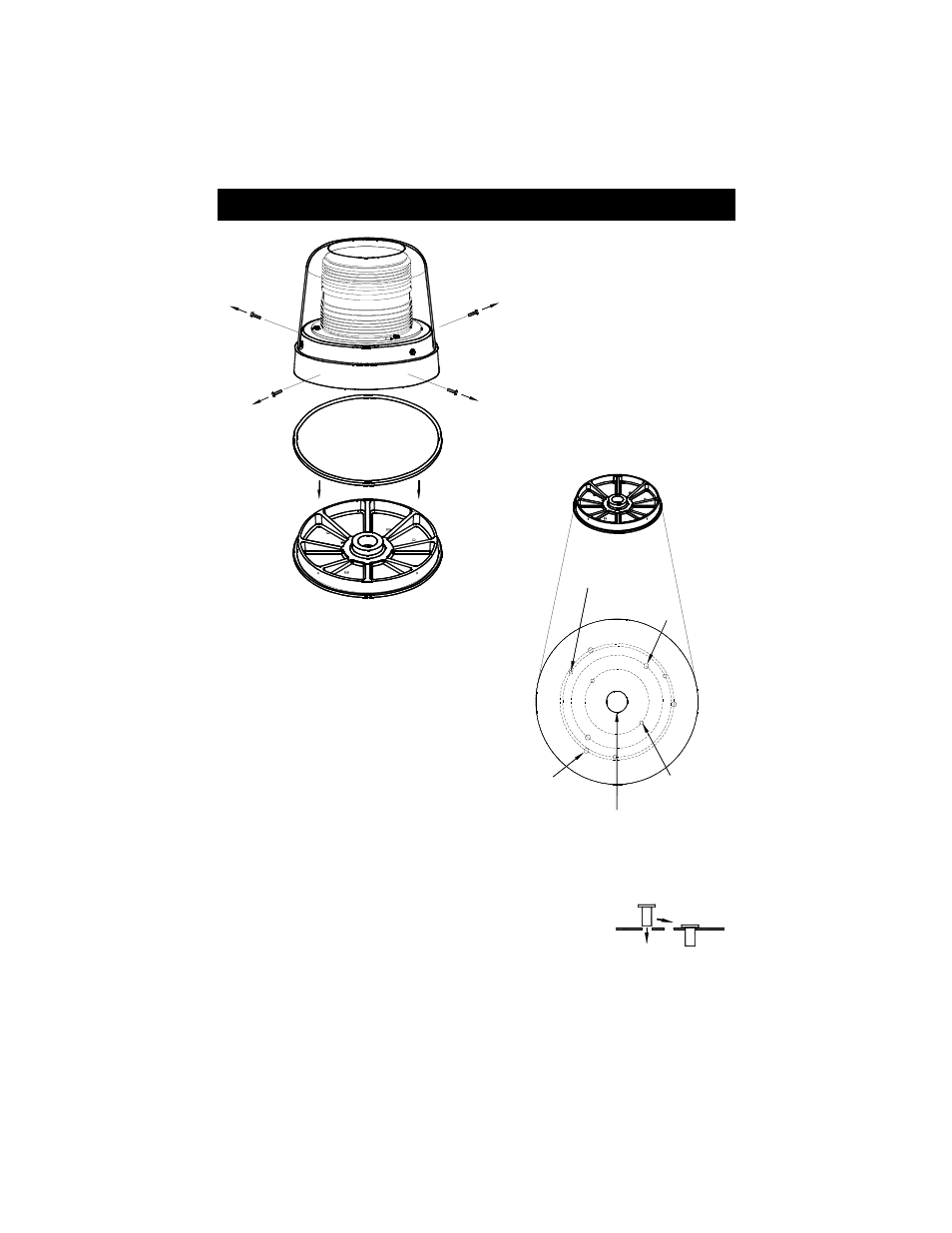

Mounting Plastic Base Models

Gasket

Remove the 4 screws in the

side of the Aluminum housing

and slide the plastic base out

Plastic Mounting Base

1. Remove the four screws in the side

of the aluminum housing.

2. Slide the plastic base out of the

aluminum case. Take care not to

damage the gasket when separating

the plastic base from the aluminum

case.

0.189" Diameter

on 1.75" Radius

2 @ 180°

1" NPT THREADED

PIPE MOUNT

0.261" Diameter

on 3.125" Radius

3 @ 120°

101-AP

0.196" Diameter

on 2.975" Radius

3 @ 120°

0.264" Diameter

on 2.5" Radius

2 @ 180°

5. Remove the plastic mounting base and drill a 3/8" hole in the marked locations. Then, if

applicable, drill a 3/8" hole for the wires in the center of the outer holes.

CAUTION: Take care not to drill through the headliner of the vehicle below.

6. Push the enclosed rubber well nuts through the outer holes until the

bottom side of the wider lip rests on the surface of the vehicle.

7. Route the wires through the center hole, if applicable and align the holes with the well

nuts. Install the screws through the base, into the well nuts, and tighten until snug.

8. Once the plastic mounting base is installed on the vehicle, you may replace the light on

the base and reinstall the four screws that affix the light to the plastic mounting base.

3 Locate the various knockouts on the bottom

of the base and determine which mounting

holes will work best for your application.

Clear the knockouts using a punch or other

appropriate tool.

4. Using the plastic mounting base as a

template, mark the appropriate holes on the

mounting surface. Take care to ensure that

the base does not move while you are

marking each of the holes.