Southbend Cheese Melters User Manual

Page 18

I

NFRARED

C

HEESE

M

ELTER

OWNER’S MANUAL 1186531 REV 3 (9/14)

PAGE 18

OF 22

T

ROUBLESHOOTING

A

CCESS

T

O

S

ERVICEABLE

P

ARTS

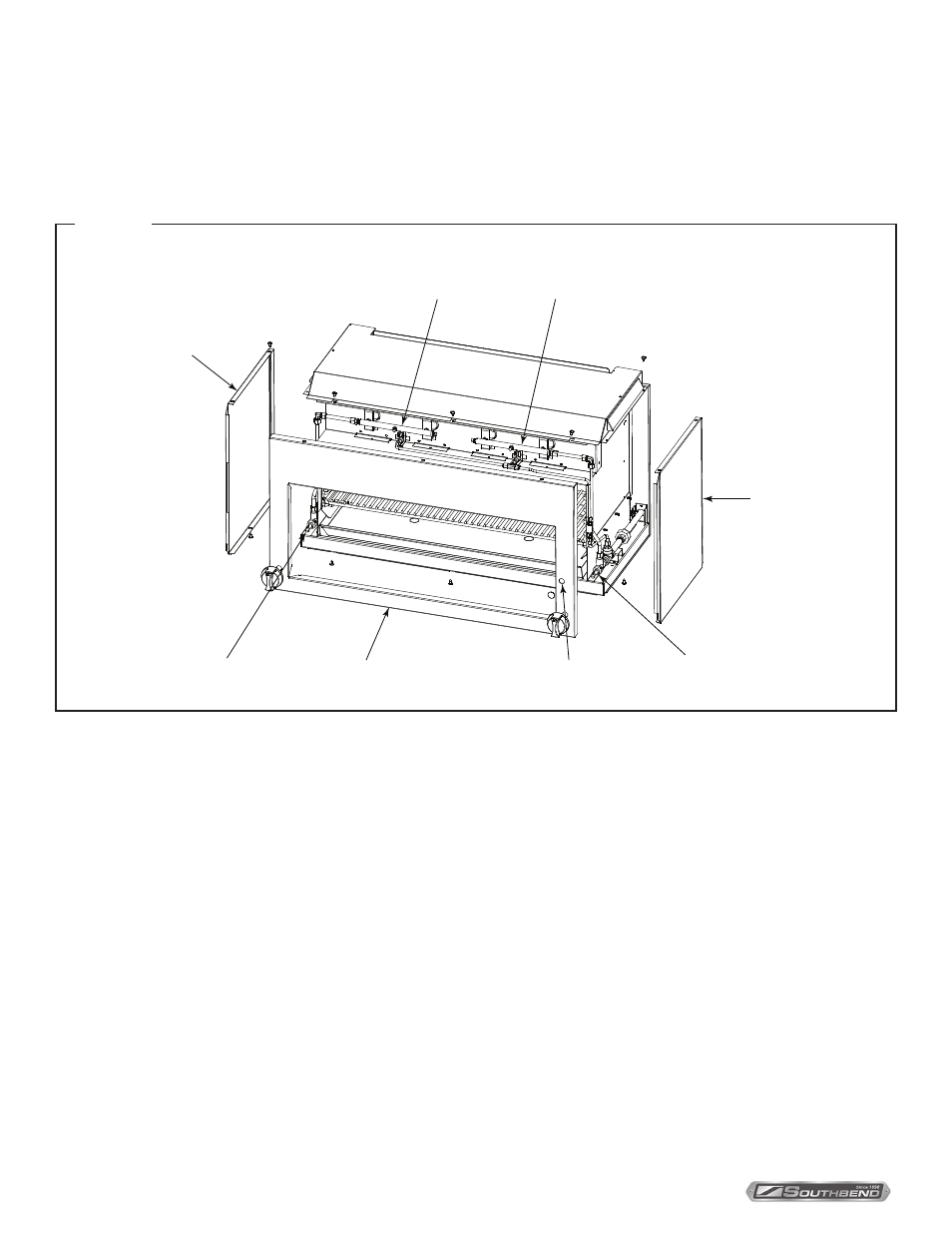

Some serviceable parts are only accessible by removing body side panels and the front panel.

The main front panel is fastened with six sheet-metal screws. To remove the front panel, remove these screws, as well as

the burner-control-valve knobs. The main front panel can then be pulled forward and removed. Each body side panel is

fastened with two sheet-metal screws. Remove body-side screws and slide the body side forward and away from the unit.

Figure 7

Access to Serviceable Parts

Body Side

Body Side

Left Pilot

Right Pilot

Burner Valve Right

Burner Valve Left

Front Panel

Dual-Pilot Adjustment-Screw Hole

If necessary (or convenient), wall-mounted and flue-riser-mounted models can be un-mounted for servicing or repairs.

Use two people since the cheese melter weighs as much as 265 pounds (120 kilograms). Refer to the installation

procedure in the previous section of this manual for guidance.

A

DJUSTMENT OF

C

HEESE

M

ELTER

P

ILOTS

The pilots are adjusted at the factory. If later the pilots are over-adjusted to the point where the flame is leaving its port, or

“blowing off,” the result is an unstable condition in which the pilot may extinguish. If necessary, adjust the pilots using the

following procedure:

1. If necessary, light the pilots.

2. Locate the pilot adjustment screw (which adjusts both pilots). It is a small slotted screw located on the pilot valve,

and is accessed though the hole in the front panel above the right control-valve knob. On flame-failure option units,

the adjustment screw is located on the valve, and each pilot is adjusted separately.

3. Turn the pilot adjustment screw to adjust the size of the pilot flames. The flame on each pilot should be large enough

to extend along the flame carrier to the burner surface.

A

DJUSTMENT OF

C

HEESE

M

ELTER

B

URNERS

The infrared burners require no air adjustment after they have left the factory. If a major change in burner operation is

noticed, check for obstruction of airflow, around the orifice. Burner performance is affected by (a) orifice size, (b) pressure,

(c) injection, and (d) primary airflow. The burner orifice must be centered within the air mixer opening.