Sioux Tools SRS10S STRAIGHT User Manual

Page 3

3

INSTALLING CUTTERS

• Remove the nose piece.

• Press the lock button to lock the driver shaft.

• Screw the cutter into the driver shaft.

• Install the nose piece.

Make sure the nose piece inside diameter matches the cutter outside diameter.

• Adjust the depth of cut with the adjusting ring to cut rivet flush with the surface.

It is best to initially adjust the tool to cut the rivet slightly above the surface and then continue to adjust the tool in incre-

ments until the rivet is cut flush with the surface.

SHAVING OR MILLING RIVETS

• Place the nose piece over the rivet. The stabilizer will aid in maintaining proper alignment with the rivet.

• Start the tool.

• Press down on the tool until the cutter contacts the rivet.

• Continue pressing until the rivet is cut flush with the surface.

If the depth of cut is properly adjusted, the cutting action will stop automatically.

• Shut off the tool and remove from the surface.

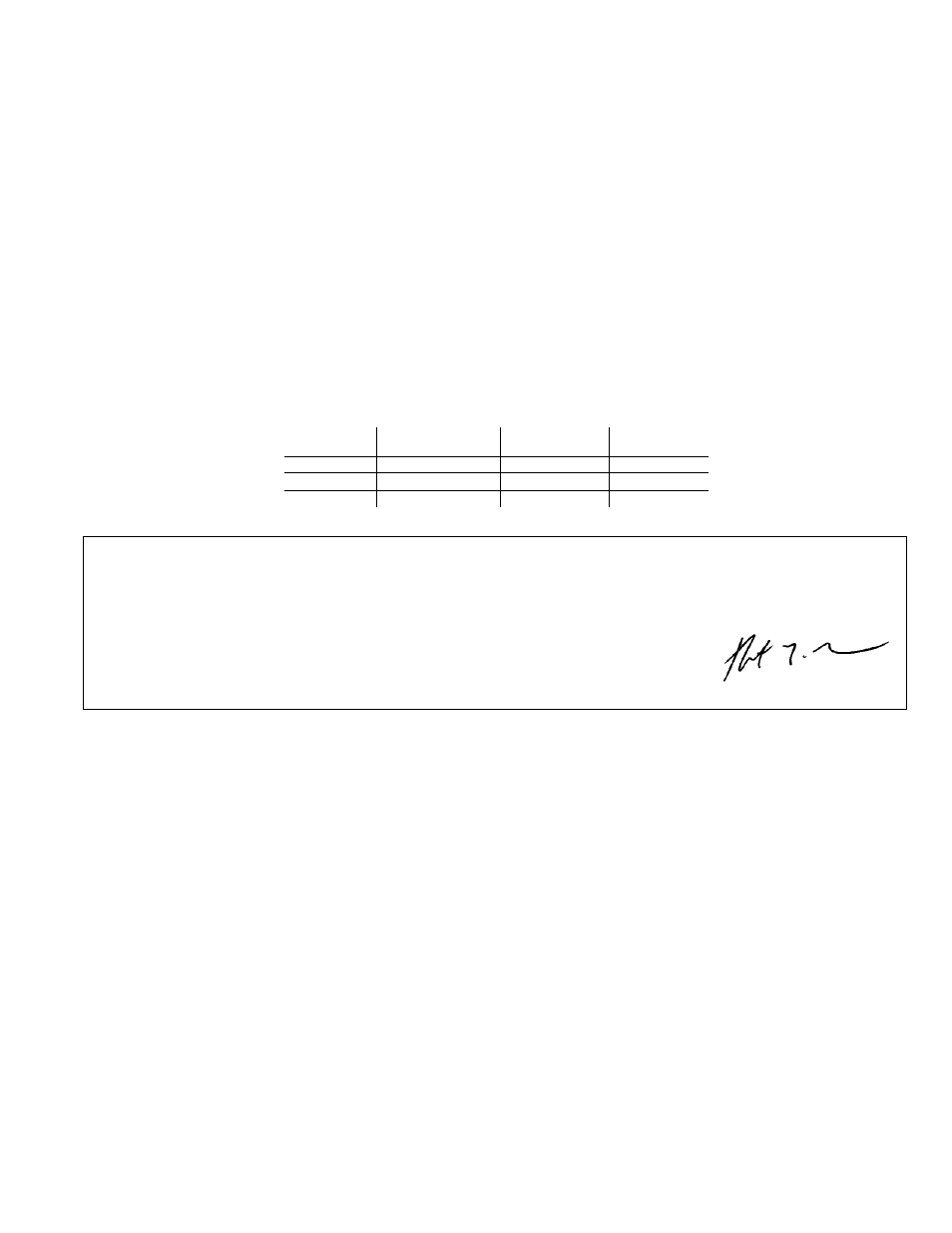

*Sound Pressure

*Sound Power

*Vibration

Catalog No.

dBA

dBA

m/s

2

SRS10P

80.0

91.6

Less than 2.5

SRS10S

80.0

91.6

Less than 2.5

*per PN8NTC1

*per PN8NTC1

*per ISO 8662

SOUND AND VIBRATION READINGS

DECLARATION OF CONFORMITY

We, Sioux Tools Inc., 250 Snap-on Drive, P.O. Box 1596, Murphy, NC, 28906, USA, declare under our sole responsibility that the products

SRS10P & SRS10S SERIES

to which this declaration relates are in conformity with the following standard or standards or other normative document or documents:

EN 792, ISO 12100-1, ISO 12100-2, ISO 8662, Pneurop PN8NTC1

following the provisions of

98/37/EC Directive.

May 1, 2009

Murphy, North Carolina, USA

Date and place of issues

Robert Hartman

Vice President and General Manager-Power Tools

Sioux Tools Inc

Name and position of issuer

Signature of issuer