Wheel and shaft maintenance, Structural maintenance – MK Plastics KVC IO&M User Manual

Page 5

M.K.Plastics Corp. Montréal, Québec www.mkplastics.com

5

500

1000

1500

2000

2500

3000

3500

4000

4500

1825

1.437

Roller

12

8

8

4

2

2

2

2

1

2225

1.437

Roller

12

8

8

4

2

2

2

2

1

2450

1.937

Roller

8

4

3

2

1

1

1

1

1

2700

2.187

Roller

8

4

3

2

1

1

1

1

1

3000

2.437

Roller

6

3

2

1

1

0.5

0.5

0

0

3300

2.437

Roller

6

3

2

1

1

0.5

0.5

0

0

3650

2.937

Roller

6

3

2

1

1

0.5

0.5

0

0

4025

3.437

Roller

6

3

2

1

1

0.5

0.5

0

0

4450

3.437

Roller

6

3

2

1

1

0.5

0.5

0

0

4900

3.437

Roller

6

3

2

1

1

0.5

0.5

0

0

5425

3.937

Roller

5

2

1

0.5

0

0

0

0

0

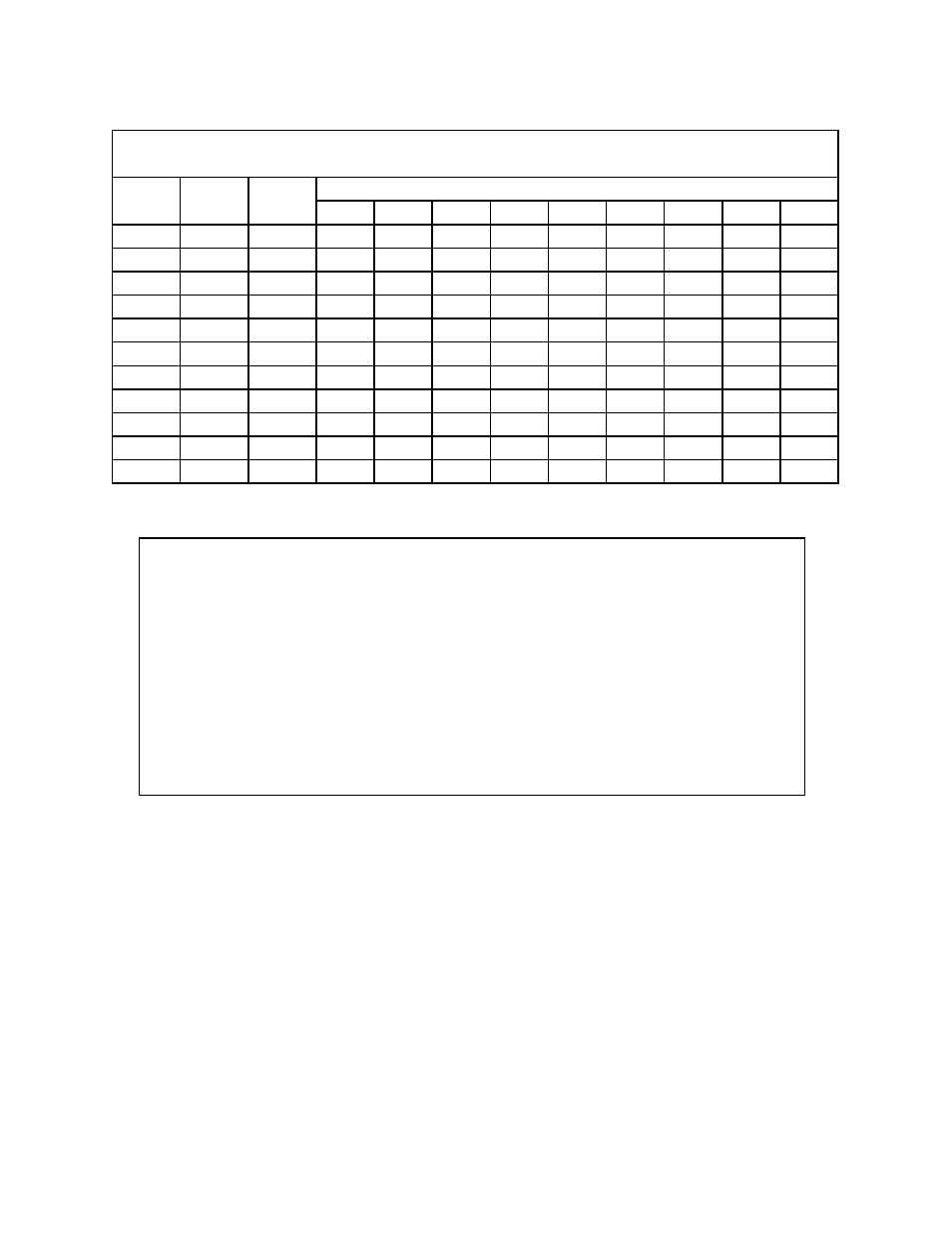

Fan Size

Shaft Dia.

Type

Speed [RPM]

Relubrication Schedule (Weeks)*

Axijet-VC & KVC (Class 3)

Table-2C. Relubricating Schedule (Weeks) – Axijet-VC & KVC (Class 3)

Wheel and Shaft Maintenance

Periodically inspect the shaft and wheel for dirt build up, corrosion, and signs of excess stress or fatigue.

Clean the components. If the wheel is removed for any reason, make sure that it is securely attached to

the shaft before restarting the fan.

Structural Maintenance

All structural components or devices used to support or attach the fan to a structure should be checked at

regular intervals. Vibration isolators, bolts, foundations, etc., are all subject to failure from corrosion,

erosion, and other causes. Improper mounting can lead to poor operation characteristics or fan fatigue

and failure. Check metallic components for corrosion, cracks, or other signs of stress. Concrete should be

checked to insure the structural integrity of the foundation.

*Suggested lubrication interval under ideal continuous operating conditions. Relubricate while running,

if safety permits, until some purging occurs at seals. Adjust lubrication frequency depending on

conditions of purged grease. Hours of operation, temperature, and surrounding conditions will affect the

relubrication frequency required.

1. Lubricate with a high quality NLGI No. 2 lithium-base grease having rust inhibitors and

antioxidant additives, and a minimum oil viscosity of 500 SUS at 100°F (38°C). Some greases

having these properties are:

a. Shell - Alvania RL

b. Exxon - Ronex MP

c.

Mobil - Mobilith SHC100

d. Mobil - Mobilith SHC220

2. Lubricate bearings prior to extended shutdown or storage and rotate shaft monthly to aid

corrosion protection.