Maintenance, Warning – LEHR Eco Trimmer User Manual

Page 12

LEHR

|

ALL RIGHTS RESERVED 2008-2009

12

WARNING:

FREQUENCY

MAINTENANCE REQUIRED

REFER TO

BEFORE STARTING ENGINE

CHECK OIL

PAGE 6

EVERY 10 HOURS

CLEAN AND RE-OIL AIR FILTER

PAGE 13

FIRST CHANGE

AT 10 HOURS

CHANGE OIL

PAGE 13

EVERY 25 HOURS

THEREAFTER

CHANGE OIL

PAGE 13

EVERY 25 HOURS

CHECK SPARK

PLUG

POSITION

AND

GAP

PAGE 14

EVERY 25 HOURS

R OCKER ARM CLEARANCE ADJ USTMENT

PAGE 17

MAINTENANCE

Perform these required maintenance procedures at the

frequency stated in the table. These procedures should

also be a part of any seasonal tune-up.

NOTE: Failure to maintain your trimmer at the recom -

mended schedule may result in poor performance and/

or cause permanent damage to your trimmer

NOTE: Some maintenance procedures may require

special tools or skills. If you are unsure about these pro -

cedures call 1-866-941-LEHR for the location of your

nearest authorized service dealer.

NOTE: Maintenance, replacement, or repair of the

emission control devices and system may be performed

by any non-road engine repair establishment, individual

or authorized service dealer.

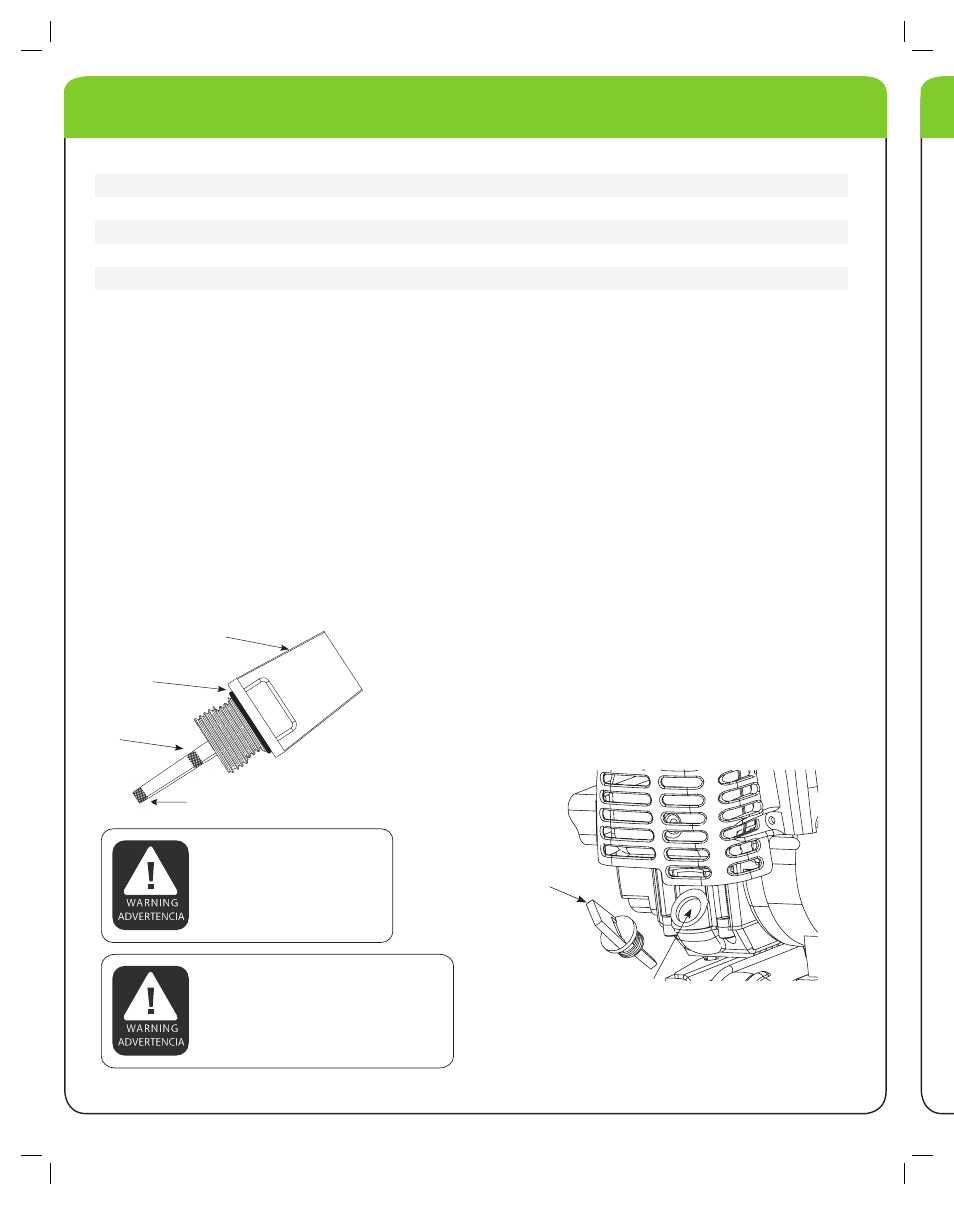

CHECKING THE OIL LEVEL

The importance of checking and maintaining the proper

oil level in the crankcase cannot be overemphasized.

Check oil before each use:

1. Stop the engine and allow to cool.

2. Place the unit on a flat, level surface to get a proper

oil level reading.

3. Keep dirt, grass clippings and other debris out of the

engine. Clean the area around the oil fill plug/dipstick

before removing it.

4. Remove the oil fill plug/dipstick and wipe off oil. Rein -

sert it all the way back in.

5. Remove the oil fill plug/dipstick and check the oil level.

Oil should be between the add and fill marks. (Fig. 17)

6. If the level is low, add a small amount of oil to the oil

fill hole (Fig. 18) and recheck. Repeat this procedure

until the oil level reaches the full mark of the dipstick:

NOTE: Do not overfill the unit.

NOTE: Make sure the O-Ring is in place on the oil fill

plug/dipstick when checking and changing the oil

(Fig. 17).

Oil Fill Hole

Oil Fill Plug/

Dipstick

Fig. 18

Oil Fill Plug/Dipstick

O-ring

Full

Add

Fig. 17

WARNING:

WHEN SERVICING, USE ONLY

IDENTICAL REPLACEMENT PARTS. USE

OF ANY OTHER PARTS MAY CREATE A

HAZARD OR CAUSE PRODUCT

DAMAGE

TO PREVENT EXTENSIVE ENGINE WEAR AND

DAMGE TO THE UNIT, ALWAYS MAINTAIN THE

PROPER OIL LEVEL IN THE CRANKCASE. NEVER

OPERATE THE UNIT WITH THE LEVEL BELOW

THE BOTTOM OF THE DIPSTICK.