1 general data 2 flue and ventilation – Glow-worm Ultimate 40CF User Manual

Page 6

6

221785B

On completion test the gas installation for soundness using the

pressure drop method and suitable leak detection fluid, purge

in accordance with the above Standard.

1.6 Electrical Supply

WARNING: This boiler must be earthed.

All system components shall be of an approved type and shall

be connected in accordance with the current issue of BS7671

and any applicable local regulations.

Connection of the boiler and system controls to the mains

supply should be through a common isolator fused at 3A,

maximum. This method of connection should be by a switched

spur box with a minimum contact separation of 3mm in both

poles. It should be clearly marked, showing its purpose,

preferably positioned close to the boiler.

Alternatively an unswitched socket outlet and three pin plug,

fused 3A, to the current issue of BS1363 may be used.

Wiring to the boiler must be PVC insulated cable at least

0.75mm

2

(24/0.20mm) to the current issue of BS6500 Table 16.

1.7 Contents of Packaging

The boiler is delivered in one pack which contains:

Boiler with outer case and wall frame, side panels, burner,

combustion chamber shield, flueway baffle and loose items

pack.

1.8 Water System

The boiler shall only be used on an unrestricted open vented

system with the water supply taken from a feed and expansion

tank, having a head between 1m (3ft 3in) minimum and 27m

(90ft) maximum.

1.9 Draining Tap

A draining tap must be provided at the lowest point of the system

which will allow the entire system, the boiler and hot water

cylinder to be drained.

Draining taps shall be to the current issue of BS2879.

1.10 Safety Valve

A safety valve need not be fitted to an open vented system.

1.11 Location

WARNING. Open flue boilers must not be installed in a private

garage.

The boiler must not be installed in a room used or intended to

be used as sleeping accommodation or a room containing a

bath or shower.

The boiler must be mounted on a flat wall which is sufficiently

robust to take its weight.

1.12 Boiler Clearances

Refer to diagram 4.4.

The boiler must be positioned so that at least the minimum

operational and servicing clearances are provided.

Additional clearances may be required for installation.

If fixtures are positioned next to the boiler they should be made

removable for access to pipework.

Sufficient clearance must be left in front of the boiler for

servicing.

1.13Heating System Controls

The heating system should have installed: a programmer and

room thermostat controlling the boiler.

Thermostatic radiator valves may be installed in addition to the

room thermostat.

Note: For further information, see The Building Regulations

1991 - Conservation of fuel and power, 1995 edition - Appendix

G, table 4b.

Important Note

The boiler is fitted with a Flue Blockage Safety Device, which

will shut down the boiler if there is an unacceptable spillage of

products at the draught diverter.

This safety device MUST NOT under any circumstances be

interfered with or put out of action.

The safety device must only be replaced with the Glow-worm

parts.

2.1 Flue Connection

The integral draught diverter makes the combustion performance

independent of conditions in the secondary flue, but an efficient

flue is necessary to ensure a trouble free installation.

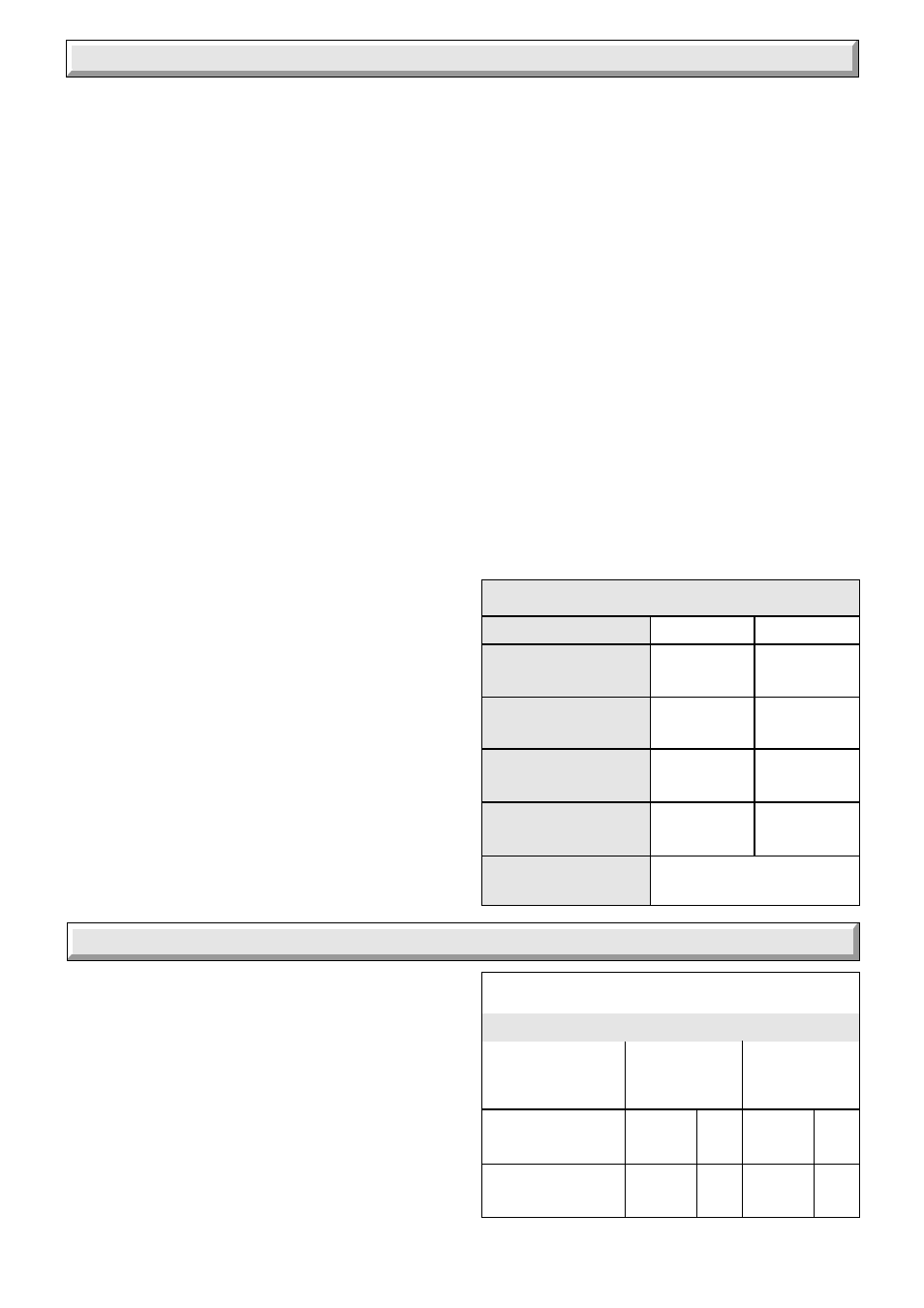

COMPARTMENT

VENTILATION

REQUIREMENTS

ULTIMATE 40CF

COMPARTMENT AIR VENT TABLE 2.

FROM ROOM

OR SPACE

140cm

2

22in

2

278cm

2

44in

2

70cm

2

11in

2

139cm

2

22in

2

HIGH LEVEL

LOW LEVEL

VENT AREA

VENT AREA

FROM

OUTSIDE

TABLE 1

RANGE RATING

Min.

NOMINAL

kW

HEAT INPUT

(GROSS)

Btu/h

NOMINAL

kW

HEAT

OUTPUT

Btu/h

BURNER

mbar

SETTING

PRESSURE

in.w.g

APPROX.

m

3

/h

GAS

RATE

ft

3

/h

BURNER :- FF2029

PILOT :- 7215

INJECTOR

MARKING

11.69

15.36

39,900

52,400

ULTIMATE 40CF

RANGE RATING

Max.

8.1

14.2

3.3

5.7

8.79

11.72

30,000

40,000

1.13

1.47

40

52

1 General Data

2 Flue and Ventilation