10 commissioning – Glow-worm Compact 100E User Manual

Page 23

23

221894A

10 Commissioning

6989

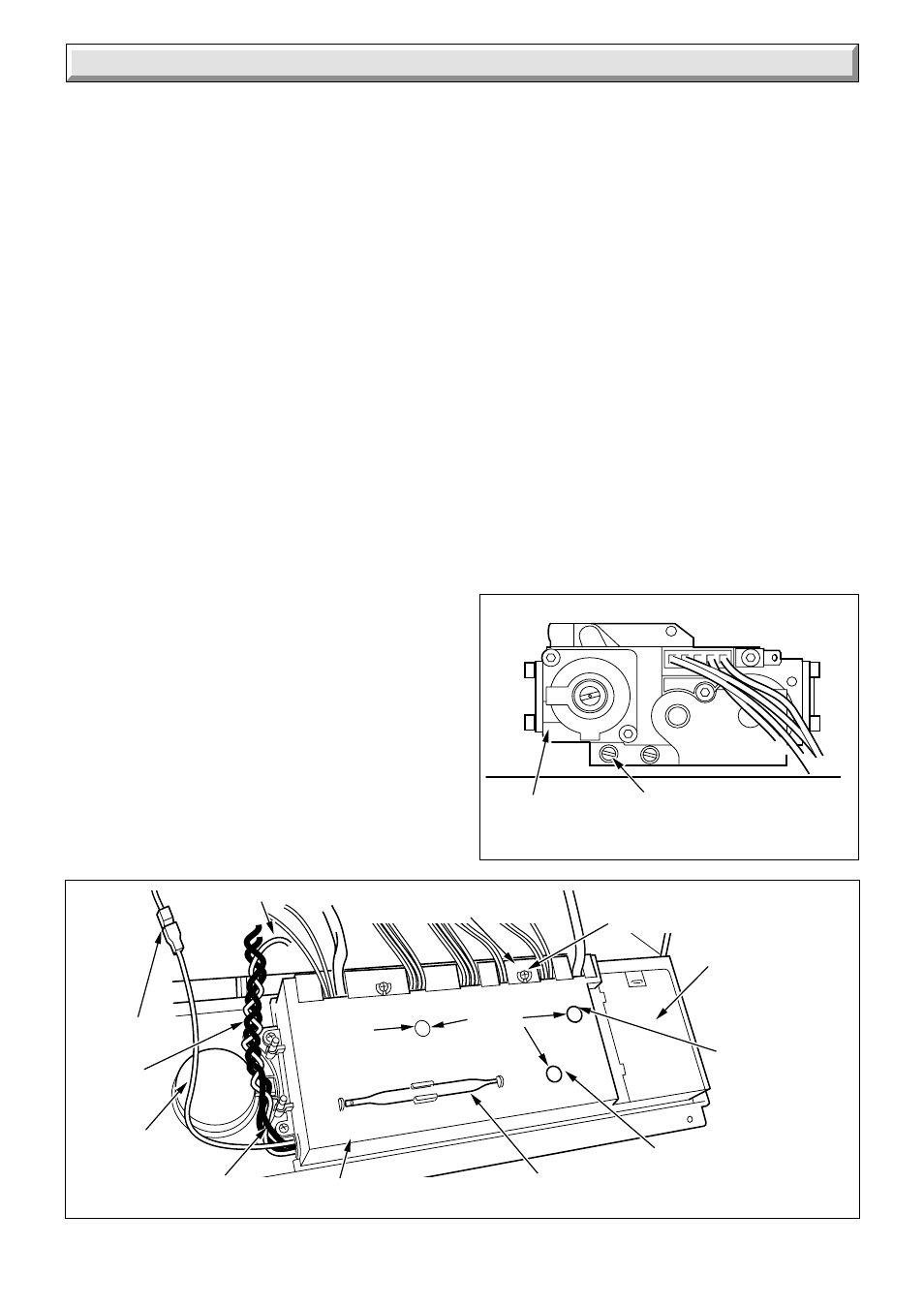

Diagram 10.1

7811

BURNER

PRESSURE

TEST POINT

10.8 Ignition Rate

Set the mains electrical switch “B” to 0, located on the controls

fascia, see diagram 4. (Instructions for Use).

Disconnect the sensing lead at the connection, see diagram

10.2.

Set the mains electrical switch “B” to 1. The electrode will

continue to spark for (10 seconds approx.) to enable the ignition

to be set and checked before going to lockout. Check the ignition

rate is set to 6.0 mbar +/-1.0 mbar, adjust if required by turning

the ignition rate setting potentiometer using the adjustment tool

supplied, If this is not achieved before the boiler goes to lockout

the process can be repeated as required by pressing the rest

button “G”, see diagram 4. (Instructions for Use). When set,

switch the mains electrical switch “B” to 0. Reconnect the

sensing lead.

Set mains electrical switch “B” to 1, depress the rest button “G”

if required. Check the appliance operates correctly.

Isolate the boiler from the electrical supply.

Replace plastic plugs, screw cap and adjusting tool.

Disconnect the pressure gauge, tighten the burner pressure test

point screw . Test for gas soundness. Take care not to splash

any of electrical components.

Refit the control fascia.

10.9 Temperature Settings

The maximum temperature setting for the domestic hot water

outlet is 65

o

C.

The maximum flow temperature setting for central heating is

80

o

C.

10.10 Heating System - Commissioning

Check that all remote controls and integral clock are calling for

heat.

Fully open all radiator valves.

Set the heating system in operation and balance the radiators.

Refer to Section 4.6 and diagram 4.1.

Allow the system to reach maximum temperature then switch

off, isolate the boiler from the electrical supply and drain the

system rapidly whilst still hot.

Remove the inner case front.

Fill and vent the system as described in Section 10.2 “Filling the

Central Heating Circuit”. Add inhibitor, if applicable, refer to

Section 4.9 “Corrosion Inhibitor”.

GAS

CONTROL

VALVE

Diagram 10.2

CABLE ENTRY COVER

CLOCK-TIMER

COVER

CONTROL BOARD

COVER

SECURING

SCREW (4)

SECURING SCREW (2)

Slacken do not remove

BURNER PRESSURE

ADJUSTING TOOL

DOMESTIC HOT

WATER BURNER

PRESSURE

POTENTIOMETER

HEATING

BURNER PRESSURE

POTENTIOMETER

PLASTIC

PLUGS

Lower the pressure to the initial cold fill design pressure, using

the external draining tap, close to the boiler, refer Table 1 and

Section 4.10.

10.11 Completion

Fit the side panels, hook into the threaded lugs at the top. see

diagram 10.4.

Fit the case base, slide back engage the rear lugs, secure with

four screws, see diagram 10.3.

Fit the outer case front by locating it on one side then wrap it

around locating it on the opposite side, slide down locating on

to the threaded lugs at the top and behind the controls cover at

the bottom, secure with nuts ,see diagram 10.5.

Set the boiler and any remote heating control to the desired

settings, then close the control cover door.

10.12 Instruct the User

Instruct and demonstrate the lighting procedure, then advise

the user of the efficient and safe operation of the boiler.

Instruct and demonstrate the operation of any heating system

controls.

Advise the user on the use and maintenance of any scale

reducer and pass on any relevant instructional documents.

Advise the user that to ensure the continued efficient and safe

operation of the appliance it is recommended that it is checked

and serviced at regular intervals. The frequency of servicing will

depend upon the particular installation and usage, but in general

once a year should be enough.

CHASSIS EARTH LEAD

CONNECTION

SENSING

LEAD

IGNITION

LEAD (2)

IGNITION

RATE SETTING

POTENTIOMETER