4 heating system – Glow-worm Compact 100E User Manual

Page 11

11

221894A

0.0

1.0

2.0

3.0

4.0

5.0

6.0

0

5

10

15

20

25

30

Circuit flow rate (l/min)

Remaining conveying capacity (m H

2

O)

0

10

20

30

40

50

60

∆

t (°C)

Dt at 100000 btu output

Dp (M H2O)

4.1 General Notes

The boiler is intended for use in a sealed system only.

4.2 Safety Valve

The safety valve is an integral part of the boiler.

It cannot be adjusted but has a manual test device.

4.3 Pressure Gauge

A pressure gauge is incorporated into the boiler to indicate the

system pressure.

The gauge has a cold fill set pointer.

4.4 Pump

The circulation pump is integral with the boiler.

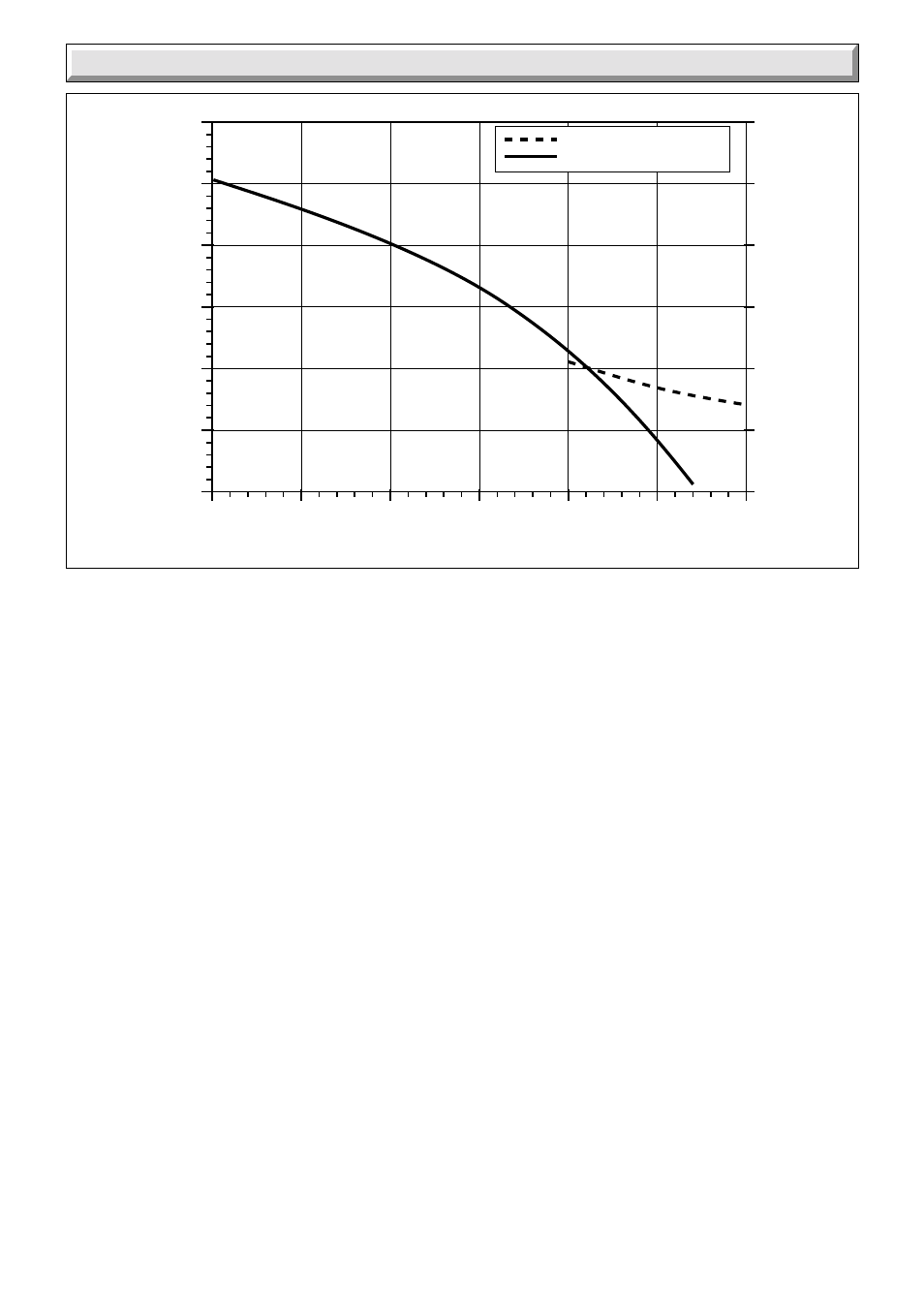

The remaining circulating pressure head available from the

boiler is shown in diagram 4.1, Glow-worm pump.

4.5 Expansion Vessel

The boiler has an integral expansion vessel with a capacity of

6 Litres. If the system water content exceeds the maximum

quoted in Table 1, Data, an additional vessel should be connected

into the system as close as possible to the central heating return

connection of the boiler, see diagram 4.2.

The charge pressure shall not be less that the static head at the

point of connection, that is, the height of the top point of the

system above the expansion vessel.

4.6 Flow Rate

A valve must be incorporated in the main flow or return of the

system, valve “A” shown in the flow diagram 4.2. This valve

must be lockable and positioned so that inadvertent closure or

unauthorised interference is not possible. The design differential

can be between 11

°

C (20

°

F) and 17

°

C (30

°

F), dependent upon

the system resistance and the available pump head.

Diagram 4.1

4 Heating System

4.7 Bypass

The bypass is an integral part of the boiler.

4.8 Filling Sealed Systems

An optional extra filling loop is available Part No. 457120

Provision for filling the system at a low level must be made.

Three methods of filling are shown in diagram 4.3.

There must be no permanent connection to the mains water

supply, even through a non-return valve.

NOTE: It is important that fittings used for connection to potable

water comply with the water undertakers requirements.

4.9 Corrosion Inhibitor

If an inhibitor is to be used in the system, contact the inhibitor

manufacturer so that they can recommend their most suitable

product.

When fitting the boiler into an existing system, special care

should be taken to drain the entire system, including radiators,

then thoroughly cleaning out before fitting the boiler whether or

not adding an inhibitor.

4.10 Draining

A draining tap must be provided at the lowest points of the

system, which will allow the entire system to be drained. An

additional draining tap MUST be fitted close to the boiler.

The flow and return isolation valves are provided with drain

points for boiler heat exchanger drainage.

7486