Maintenance, 3 fault codes – Glow-worm Betacom2 User Manual

Page 30

0020145065_01 - 09/12 - Glow-worm

14.2 fault memory

• This menu allows you to display the 10 most recent failure

codes registered by the appliance.

• In order to display the fault code memory, simultaneously

press the buttons and for more than 7 seconds.

• The screen will display the first fault "1." (record) and after

"XX" (fault code).

• To display the other faults registered by the appliance, press

the button or .

• Press button

for more than 3 seconds to exit this menu.

• To erase the fault memory registered by the appliance, consult

the “Installation adjustments” chapter and use code “d.94”.

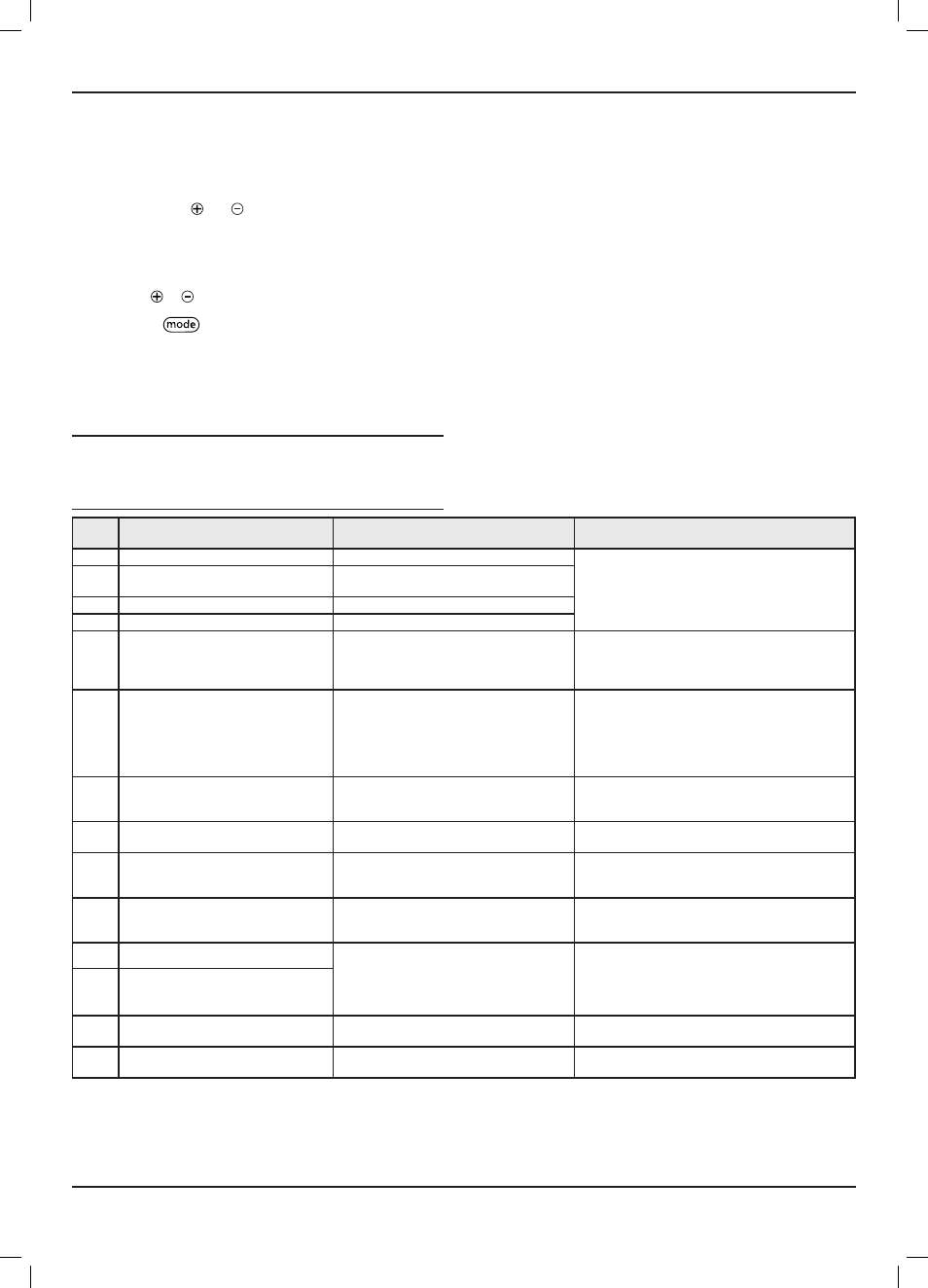

14.3 fault codes

i

IMPORTANT:

The faults described in this chapter should be carried

out by a qualified engineer and if needed by the After

Sales Service.

fault

codes Description

Cause

Solution

F00

Flow heating temperature sensor fault

Sensor open circuit

• Check the sensor’s connections.

• Check the wiring harness.

• Check the sensor.

F01

Return heating temperature sensor fault Return heating temperature sensor

disconnected

F10

Flow heating temperature sensor fault

Sensor short-circuit

F11

Return heating temperature sensor fault Return heating temperature sensor shorted.

F20

Overheating fault

Overheating safety device activated (97°C)

• Check the operation of the pump.

• Check the wiring harness.

• Check that the flow and return heating isolation

valves are open.

F22

Water pressure of the installation (<0.3

bar)

Return water valve closed

Pump disconnected

Leak in the installation

• Fill the installation.

• Purge the installation.

• Check the pump connections.

• Check the flow and return heating sensor

connections.

• Check that there are no leaks.

F23

Maximum temperature difference

reached between return and flow

heating

Water circulation fault

• Check the flow and return heating sensor

connection.

• Check the pump speed.

F24

Water circulation fault

Malfunction of the pump (excessively rapid

temperature increase)

• Check that the flow and return heating isolation

valves are open.

F26

Fault in gas valve motor.

Disconnected or defective cables

• Check the gas valve connections.

• Check the operation of the gas valve.

• Check the operation of the condensate pump (option).

F27

Flame detection fault.

Abnormal flame detection

• Check the flame detection electrode.

• Check the main board.

• Check the igniter unit.

F28

Ignition fault

No return gas / Insufficient gas flow

Gas valve incorrectly adjusted

Defective firing electrode and flame control /

Defective igniter unit

• Check the return gas circuit (gas valve open).

• Check the observe the flame picture and check the

CO

2

setting.

• Check the igniter unit connections.

• Check the state of the electrode (corrosion).

F29

Loss of flame during operation

F32

Incorrect air pressure

Incorrect fan speed.

• Check the entire flue system.

• Check the fan’s electrical connections.

F49

EBUS voltage fault

Fault in EBUS line

Short circuit in EBUS connector

• Check that the eBus controls are fitted and wired

correctly.

MAINTENANCE

- 28 -