1 general – Glow-worm BBU 45/4 User Manual

Page 6

6

2000225023C

C

L

BOILER

FLOW

PUMP

TO HEATING

CIRCUIT

INDIRECT

CYLINDER

1 METRE MIN

27 METRE MAX

RETURN

150mm

1 General

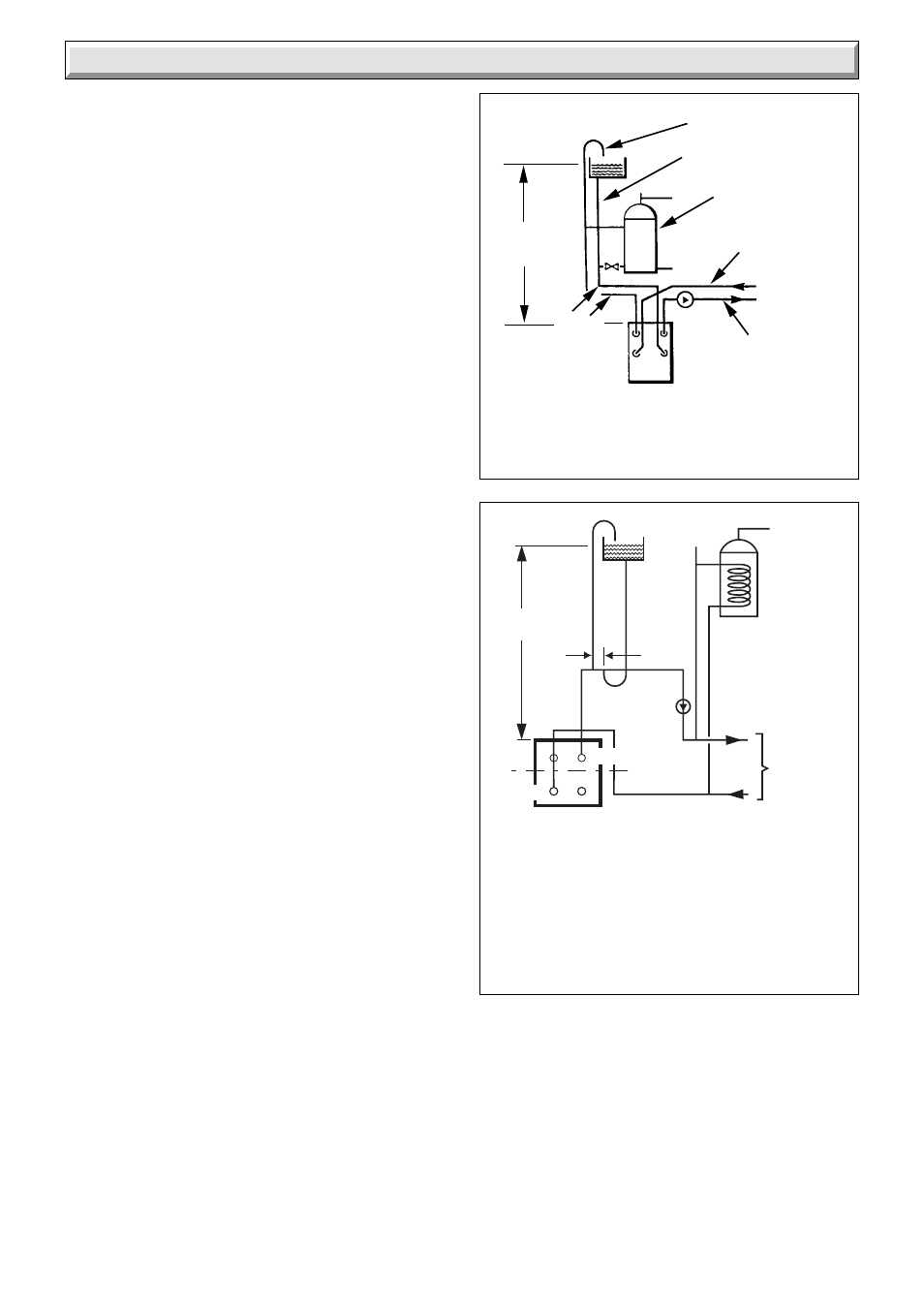

Diagram 1.5

9625

FULLY PUMPED SYSTEM

(DIAGRAMMATIC)

Diagram 1.4

PUMPED HEATING & GRAVITY DOMESTIC HOT

WATER (DIAGRAMMATIC)

9624

HEATING

SYSTEM

PUMP

28mm

1m MIN.

27m MAX.

INDIRECT

CYLINDER

15mm COLD FEED

22mm VENT

1.7 Hot Water Cylinder

The back boiler is suitable for open vented systems using an

indirect cylinder. The cylinder must be fitted to the manufacturer’s

recommendations and the system must conform to the

requirements of the current issue of BS5449.

It is recommended that the cylinder be fitted with some form of

temperature control.

1.8 Frost Protection

If the position of the boiler is such that it may be vulnerable to

freezing it should be protected as specified in the current issue

of BS5422.

It is also recommended that a frost thermostat is fitted.

1.9 Draining Tap

System

A draining tap must be provided at the lowest point of the system

which will allow the entire system, the boiler and hot water

cylinder to be drained.

Draining taps shall be to the current issue of BS2879.

Boiler

A draining point is fitted at the bottom of the side of the heat

exchanger where the water connections are located, see diagram

1.1.

When draining is required cover the controls to avoid water

damage.

1.10 Safety Valve

A safety valve need not be fitted to an open vented system.

1.11 Boiler Location

This back boiler unit MUST NOT be installed in a private garage

or in a room containing a bath or shower or a room used or

intended to be used as sleeping accommodation.

1.12 Sealed Water System

A kit and instructions, part number 2000463000, is available to

enable the back boiler to be used on a sealed water system.

Please give the serial number of the back boiler when ordering

the kit.

1.13 Inhibitor

Attention is drawn to the current issue BS5499 and BS7593 on

the use of inhibitors in central heating systems.

If an inhibitor is to be used, contact a mnufacturer for their

recommendations as to the best product to use.

If using in an existing system take special care to drain the entire

system, including the radiators, then thoroughly cleaning out

before fitting the boiler whether or not adding an inhibitor.

The COLD FEED PIPE may be connected to flow

pipe, adjacent to the open vent pipe as shown.

(THERE MUST ALWAYS BE A COLD WATER

PATH TO THE RETURN CONNECTION OF THE

BOILER)

22mm

22mm