ENMET PID-Guard User Manual

Page 8

PID-G

UARD

ENMET Corporation

6

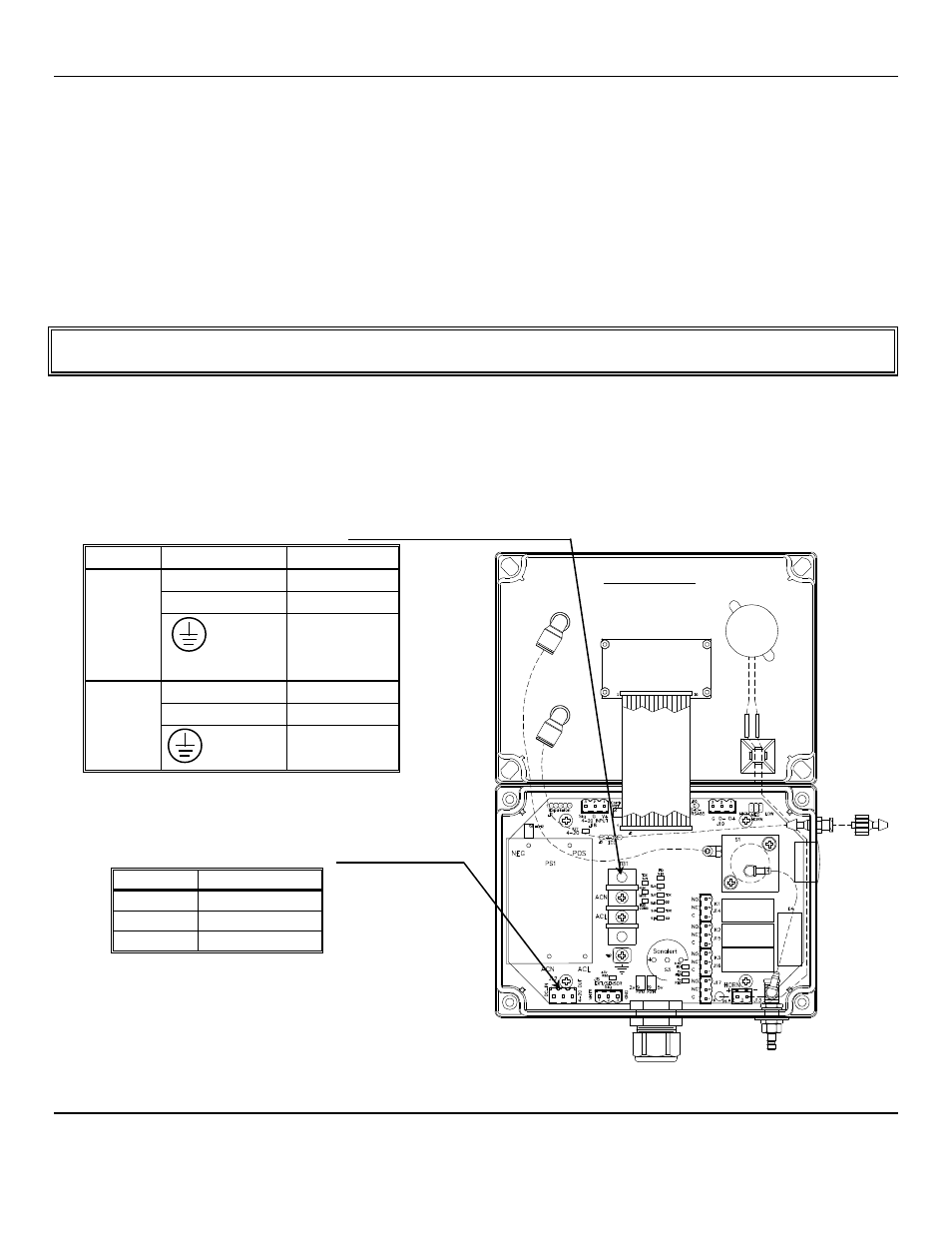

3.2 Wiring the PID-G

UARD

The electrical installation should conform to appropriate electrical codes, such as the National Electrical Code in the United

States.

W

ARNING

:

The compliance of the installation to appropriate codes is not

ENMET

’s responsibility.

The

PID-G

UARD

should be powered through circuit breakers provided for this purpose.

3.2.1 Air Supply

Tap the pipe or tank containing the air and use appropriate fittings to connect the sample input hose. The instrument is

designed to operate from an air supply pressure 55

PSIG

. The sample input hose length should be as short as possible.

3.2.2 Power Supply

The input power can vary from 100 to 240

V

AC

, 50/60 Hz. Power should be connected to the Power Input Terminal

TB1

and

the Ground screw. See Figure 4 for location.

W

ARNING

:

Continuous gas detection and alarm systems (110

V

AC

/220

V

AC

/ 24

V

DC

/

12

V

DC

powered) become inoperative

upon loss of primary power. Contact factory for specifications and pricing of backup battery systems.

Upon supplying air and power to the

PID-G

UARD

:

The green power on LED is lit.

The display backlight is lit, and instrument will step through a start-up sequence: unit serial number and software revision

may be shown on the display.

The instrument may go into alarm briefly, but the sensors stabilize quickly. If the instrument persists in alarm, acknowledge the

alarm by pressing the

S

ELECT

button. If alarm persists longer than 30 minutes, call

ENMET

customer service personnel.

For DC wiring 24Vdc may be wired to J12, (J12-1)position 1 + with ground connected to (J12-2)position 2.

AC Power Supply Terminal: TB1

Label on PCB

Function

110

V

AC

TB1 ACN

Neutral

TB1 ACL

Line

Ground

Screw

AC GND

220

V

AC

TB1 ACN

Neutral

Optional

TB1 ACL

Line

Ground

Screw

AC GND

DC Power Supply Terminal: J12

Position

Function

1 +

24

V

DC

power

2

GND

3

4 - 20 mA out

Figure 4: Power Terminal Connections PID-G

UARD

Cover Inside View

Opened Upward

Attached to Base