ENMET MedAir 2000 User Manual

Page 21

M

ED

A

IR

2000

ENMET Corporation

17

5.2 Sensor Replacement

5.2.1 CO Sensor

A CO sensor must be replaced when it can no longer be calibrated. To replace a sensor, perform the following steps.

Turn off the electrical power. The sample air can continue to flow.

Open the display panel and remove the two manifold retention screws and remove the manifold. See Figure 9.

Remove the old CO sensor, which is the bottom most sensor, and replace it with a new sensor.

C

AUTION

: New sensors come with a shorting clip that must be removed for proper operation. See Figure 8.

Replace the manifold. Observe that the flowmeter reading is correct.

Turn on the electrical power.

Wait 30 minutes, then recalibrate the sensor per the instructions in Section 5.1.3. As the timer is counting down

during calibration, a voltage is displayed on the screen beside the timing count. This voltage must be between:

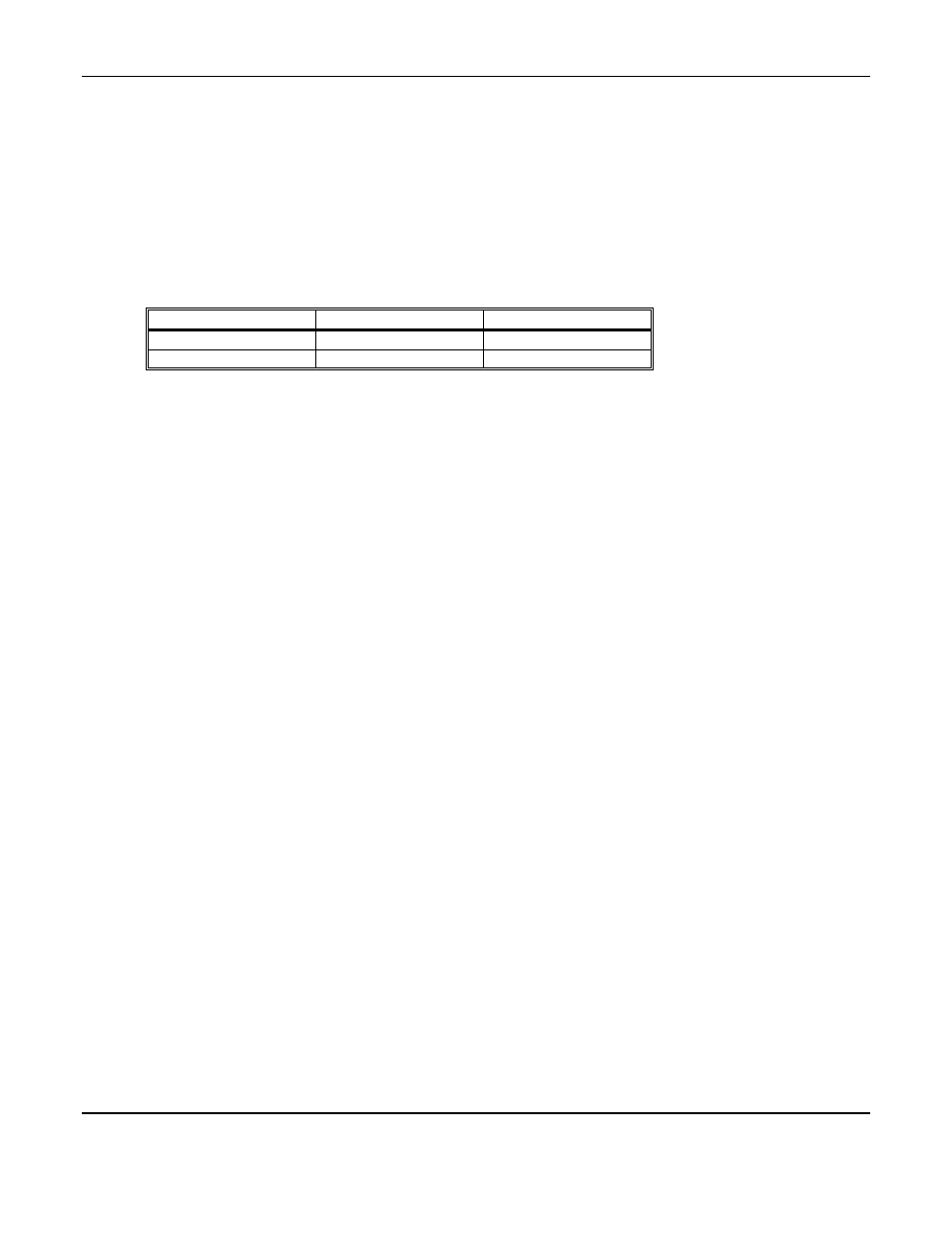

For Serial No.

Range

Adjust to

133 and above

.38V - .68V

.65V

132 and below

.59V - .68V

.64V

Adjust to: .65V if it is not between .38 – .68V. Adjust this voltage during the last 30 seconds of the calibration

interval, using the bottom most potentiometer on the sensor circuit board. See Figure 10.

Replace the manifold housing, and secure the display panel. An instrument without the manifold housing in place

is susceptible to RFI.

5.2.2 Oxygen Sensor

An oxygen sensor must be replaced when it can no longer be calibrated in clean air. To replace the sensor, follow the

general steps given for the replacement of the CO sensor, but effect a replacement of the oxygen sensor, which is the

large sensor in the center position of the manifold. After sensor installation, wait four hours before recalibrating.

When recalibrating, it is not necessary to make a voltage adjustment.

5.3 Humidifier Tube

The humidifier tube is used to assure that the CO and oxygen sensors are not subjected to extremely dry air for a long

period of time, which would decrease their useful life. Change the humidifier tube when changing a CO sensor at the

completion of its useful life.

To change the humidifier tube:

Remove the sheet metal cover from the top of the enclosure, exposing the humidifier tube. See Figure 10.

Note the coiled arrangement of the tube. Remove the old tube and replace it with the new one.

Replace the sheet metal cover.

5.4 Dew Point Sensor

Unlike the CO and O

2

sensors, the dew point sensor cannot be field calibrated. To assure correct performance, the dew

point sensor should be calibrated biyearly. To minimize instrument downtime, take advantage of the dew point sensor

exchange program available through ENMET, in which a year old dew point sensor can be exchanged for a newly

calibrated sensor. Call ENMET customer service personnel for details.

5.5 Flow Control Orifice

A 0.006-inch diameter orifice is used to set the flow rate and to drop the air pressure. It is located where the air enters

the humidifier tube, see Figure 10. In well-maintained medical air systems, this orifice should not clog. However, if

difficulty is experienced in maintaining flow rate with assured inlet pressure, remove air pressure from the equipment

and examine this orifice; replace it if necessary.

5.6 Particulate Filter Replacement

On instruments with serial numbers

S

/

N

332 and above, a filter is installed inside the enclosure, as shown in Figure 10.

To replace this filter:

Obtain a new filter

Note the correct direction of flow, as denoted by the arrow on the filter body

Remove the old filter

Replace with the new filter