Pc board repair – Elenco Practical Soldering Project Kit User Manual

Page 8

-7-

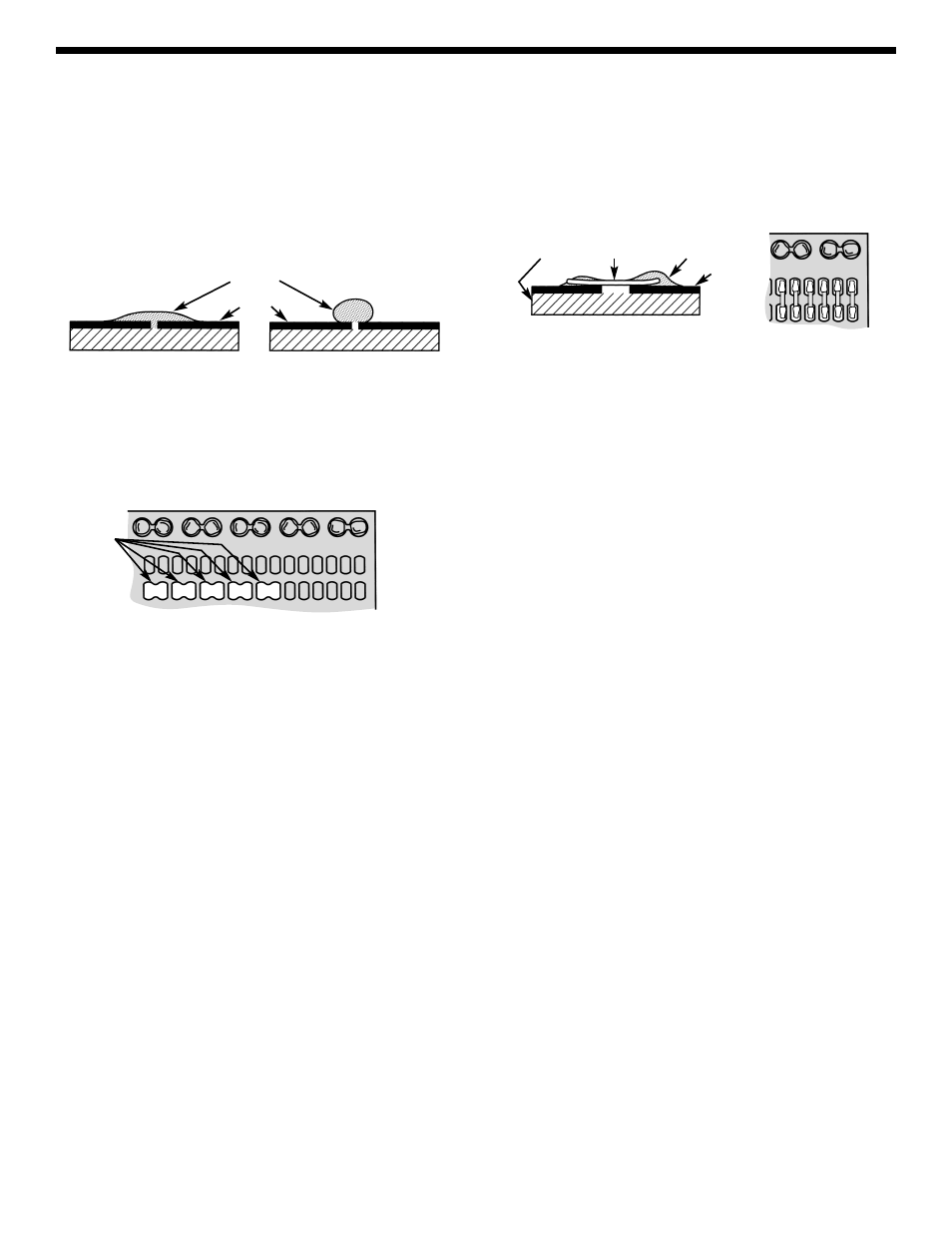

Hairline Cracks

The hairline cracks can develop in the copper foil if

the PC board is flexed. This can be easily repaired

by making a solder bridge across the two foils. The

solder should smoothly flow across the foil as shown

in Figure 8. If the solder does not adhere to the foil,

it will sit on the foil as a blob as shown in Figure 9.

1. Make five solder bridges using the second row of

single pads, starting from the left side (see Figure 10).

Reinforcing a Repair

A solder bridge repair can be reinforced using a solid

wire. Now add a wire to the five solder bridges you

just made.

1. Strip a 1/2" of insulation off one end of the wire

and then tin it.

2. Hold the tinned wire on top of the solder bridge.

3. Place the iron on the wire until the solder melts.

4. Remove the iron while holding the wire in place

against the foil. Make sure the wire does not

move until the solder hardens.

5. Check for a good solder connection.

6. Cut the wire off as close to the solder joint as

possible.

7. Practice this procedure four more times.

Wide Gaps

For wider gaps in a copper foil, a solder bridge can

not be used. A small wire would be used to bridge

the copper as shown in Figure 11. Six bridges will be

made across the two rows of small pads.

1. Place the iron on the top half of pad and then

apply the solder. Allow the solder to flow around

the pad. Then, remove the solder and the iron

and let the solder cool. The solder should be neat

and smooth.

2. Repeat Step 1 on the lower pad.

3. Strip 1/2" of insulation off one end of the wire and

then tin it.

4. Hold the wire on the top pad and then place the

iron on the wire. The solder will melt and the wire

will press down against the pad (see Figure 11).

Remove the iron while holding the wire in place

against the foil. Make sure the wire does not

move until the solder hardens.

5. Check for a good solder connection.

6. Solder the wire to the lower pad.

7. Cut the wire off as close to the solder joint as

possible (see Figure 11).

8. You can hold the wire down with a screwdriver

and resolder the wire.

9. Practice this procedure four more times on

remaining pads.

Figure 8

Figure 9

Solder

Foil

Figure 11

Solder

Foil

Bare Wire

Board

Figure 10

Solder

Bridges

PC BOARD REPAIR