Eagle Tree eLogger V2 Multi-Expander User Manual

Page 2

Copyright © 2007 Eagle Tree Systems, LLC

http://www.eagletreesystems.com

Page 2

Connecting the RPM Wire(s) to your Power System

WARNING: The wires of the Expander are designed to carry only the tiny currents required for the Expander to measure RPM. The wires must

never be connected in a way where large current could flow through them, or in a way where they could become damaged and short with other

conductors.

WARNING: High Voltages can cause electric shock. Be extremely careful when working with high voltage packs! Work with high voltages at your

own risk!

IMPORTANT: Only connect your battery pack to the MicroPower AFTER all other connections are made to the MicroPower and Multi-Expander.

There are two unconnected red wires extending from the Expander. Normally, only the wire nearest the Eagle Tree logo on the label needs to be electrically

connected to any 1 of the 3 wires leading from your ESC to your motor. The end of this wire can be soldered, clipped or otherwise electrically connected to

one of the motor wires. If you use “bullet” type plugs between your motor and ESC, it is very easy to connect the RPM sensor wire, by just stripping off ta

short piece of the insulation, and connecting the bullet plug with the stripped RPM wire inside it.

For convenience, if you plan on frequently moving the Sensor between motors, a small plug could be attached to one of the motor leads and the mating plug

attached to the “To Motor 1” wire. Or, for more portability, if it can be done safely, a short straight pin could be connected to the Sensor “To Motor 1”

wire, and the pin could be used to pierce the insulation of one of your motor wires, thus forming an electrical connection.

In the unlikely event that the Sensor provides no RPM signal when only the Motor 1 wire is connected, it will be necessary to connect the “To Motor 2” wire

to a second motor wire, as shown in Figure 3. In this configuration, two of the three motor wires will be connected to the Sensor.

Configuring and Calibrating the RPM Function of the Expander with the Windows Application

If you have not already done so, set up the Recorder software as described in your instruction manual.

To calibrate the RPM sensor, you need to know the number of “poles” your brushless motor has. This information is normally supplied by the motor

manufacturer. For “outrunner” motors, the term “poles” refers to the number of magnets in the motor (NOT the number of stator teeth, “legs,” or

“hammerheads.”) For example, if you have an outrunner with 10 teeth on the stator and 14 magnets in the flux ring, the motor has 14 poles. For “inrunner”

motors with a central magnet, the term “poles” refers to the number of magnetic poles present on each magnet (always 2, so enter a “2” for poles).

If you are uncertain about the number of poles, or want to verify you calculated correctly, a hand-held tachometer can be used to compare the RPM value

displayed real-time by your MicroPower, in a bench test (assuming it is safe for you to do this). Real-time display is available in Recorder USB Live Mode,

on the MicroPower PowerPanel, or with the Seagull Wireless Dashboard. If the value displayed is incorrect, you can change the poles setting to adjust the

displayed RPM value. For example, if your handheld tachometer reads 4000 RPM, and your Eagle Tree data shows the maximum RPM of 8000, you would

need to double the number of poles to “2.”

Click on “Tools, Calibrate Motor RPM”, select the “Brushless Motor RPM Sensor” option, and enter the number of Poles and the gear ratio.

Logging RPM

To RPM, just click “Tools, Choose Parameters to Log in the Recorder” and check the “RPM” box.

Displaying RPM in the Windows Application

To display the RPM Gauge and/or Numeric Display, click “Tools, Choose Instruments to Display on the PC Screen” and check the “Motor RPM Gauge,”

“Numeric Motor RPM” and/or “Propeller RPM/Headspeed” boxes.

Graphing RPM

To RPM, click “Graph Data/2D Chart,” select either the Left Y Axis or Right Y Axis, and select “Motor RPM” and/or “Prop RPM/Headspeed” for graphing.

Displaying RPM on the PowerPanel

Select “Tools, Configure PowerPanel Display”, and choose “Motor RPM” and/or “Prop RPM/Headspeed” for PowerPanel display.

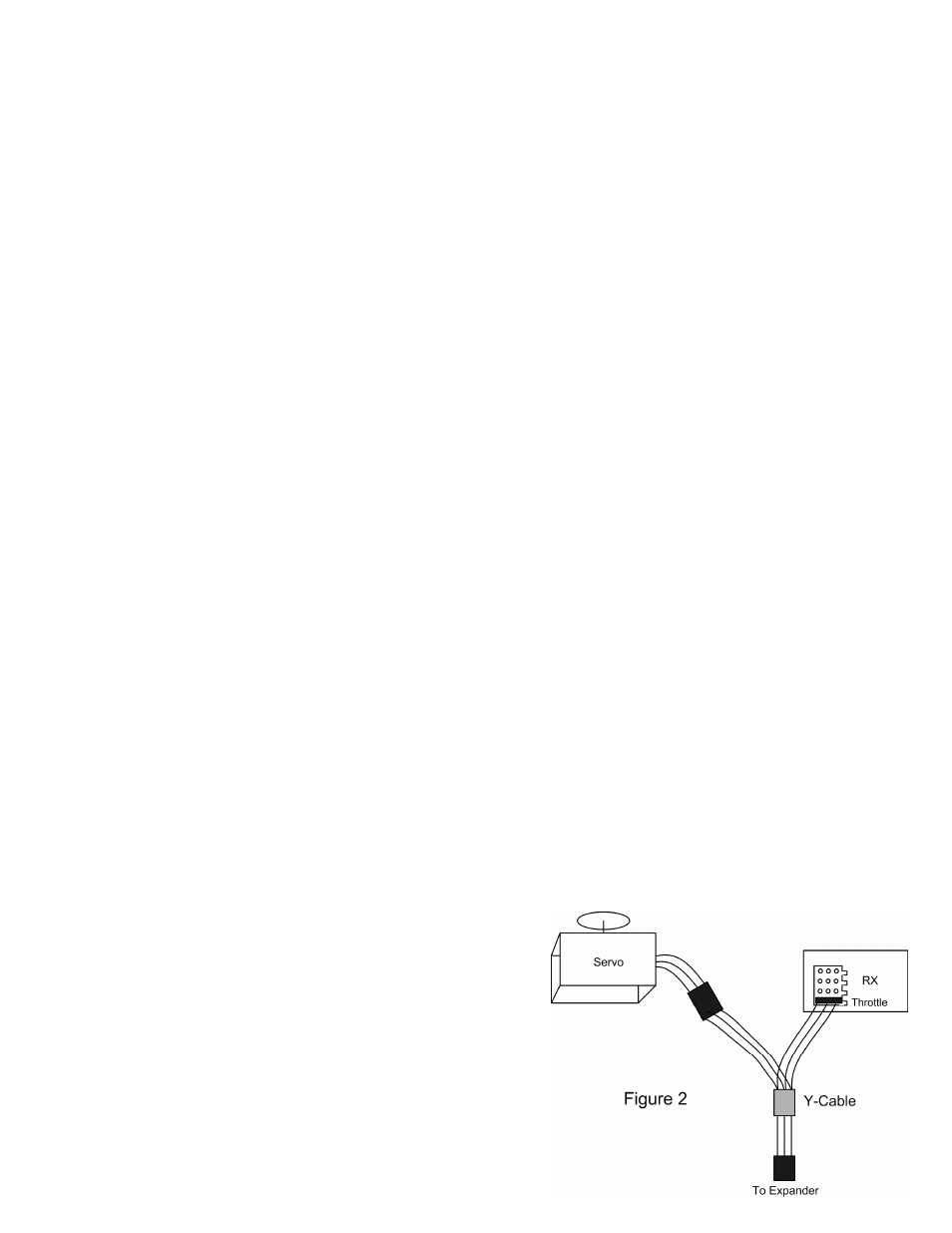

Connecting the Throttle Servo Y-Cable to your Throttle, and to the

Expander

The Expander logs servo positions by measuring the pulses coming from your receiver to

the throttle servo, via the included Y cable. The Y Cable has 3 connections. The

“Futaba” male plug (at the “base of the Y”) connects to the Expander, vertically, as

shown in Figure 1 and on the Sensor label. Only the white and red wires of the Y

cable’s Futaba male connector connect to the Expander. The black wire of the Futaba

connector is unconnected. The other two plugs of the Y cable connect to your receiver’s

throttle channel, and to your throttle servo. See Figure 2 for connections of the Y cable

to your Receiver and Servo.

IMPORTANT: Make sure you connect the battery pack to the

MicroPower only AFTER connecting the throttle Y cable to the

MicroPower (and all other connections). This is to prevent the negative side