Warning – Dunkirk DXL Series User Manual

Page 19

19

Thermostat actuates on call for heat,

completing circuit to control. Completed

circuit to control will fi rst activate circulator

and damper which will close end switch inside

damper. Completes circuit to ignition system,

ignition takes place.

In event boiler water temperature exceeds

high limit setting on boiler mounted high limit

control, power is interrupted between control

system and ignition system. Power remains

off until boiler water temperature drops below

high limit setting. Circulator continues to

operate under this condition until thermostat is

satisfi ed.

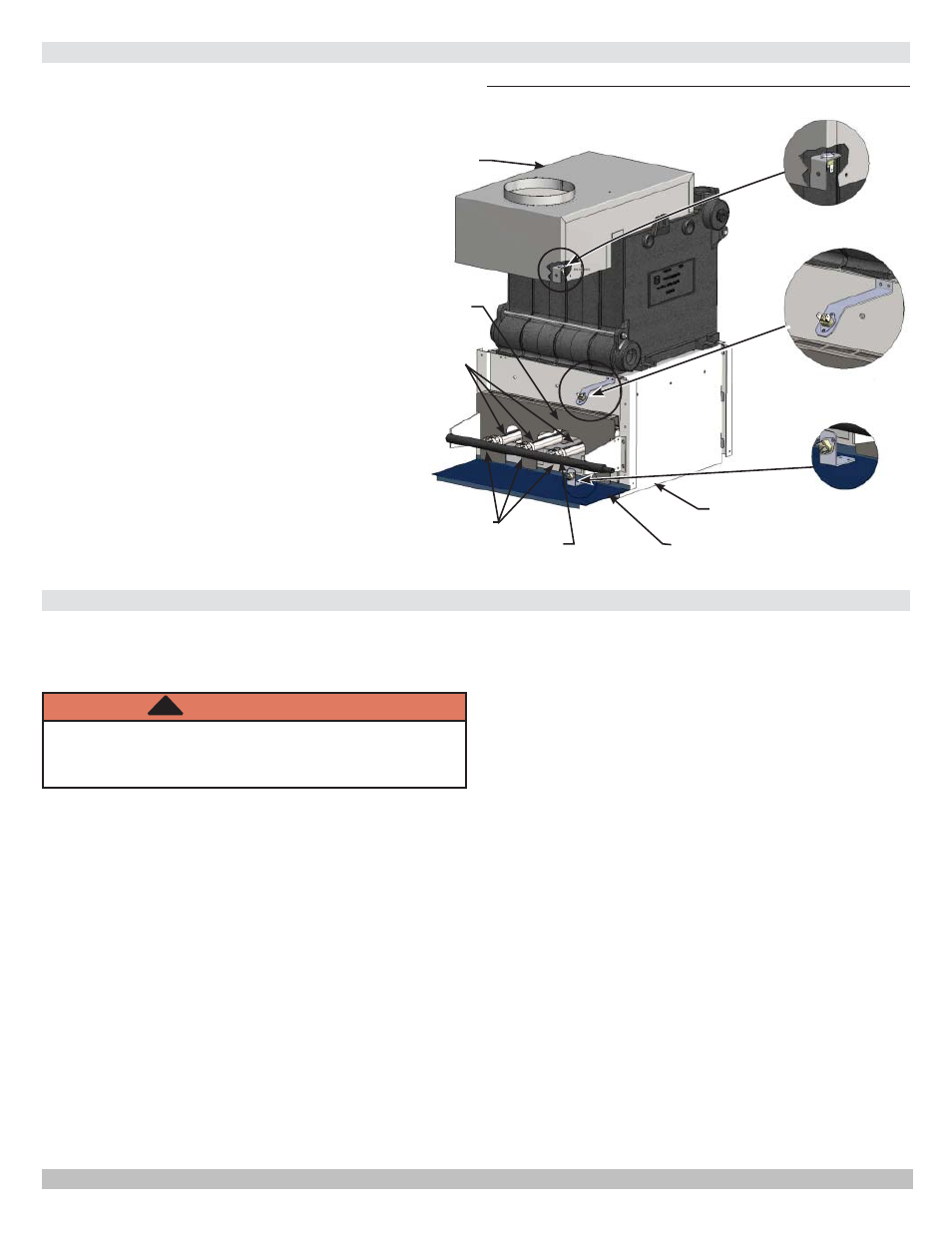

In event fl ow of combustion products through

boiler venting system becomes blocked, blocked

vent safety switch shuts main burner gas off.

Similarly, if boiler fl ue-way becomes blocked,

fl ame rollout safety switch shuts main burner

gas off. See Figure 17 . If either of these

conditions occur, do not attempt to place boiler

back into operation. Contact certifi ed service

agency.

Before seasonal start-up, have a certifi ed service agency

check boiler for soot and scale in fl ues, clean burners and

check gas input rate to maintain high operating effi ciency.

WARNING

Label all wires prior to disconnection when servicing

controls. Wiring errors could cause improper and

dangerous operation.

!

Verify proper operation after servicing

Service agency will verify system is fi lled with water to

minimum pressure and open air vents, if used, to expel any

air accumulated in the system. Check entire piping system

and, if any leaks appear, have them repaired.

Circulators need to be checked and maintained.

Refer to circulator manufacturer's instructions.

Inspect venting system at the start of each heating

season. Check vent pipe from boiler to chimney for signs of

deterioration by rust or sagging joints. Repair if necessary.

Remove vent pipe at base of chimney or fl ue and using a

mirror, check vent for obstruction and verify vent is in good

working order.

Boiler fl ue gas passageways may be inspected by a light

and mirror. Remove burner door. See Figure 20, Page 20 .

Place trouble lamp in fl ue collector through draft relief

opening. With mirror positioned above burners, fl ue gas

passageways can be checked for soot or scale.

This procedure should be followed to clean fl ue gas

passageways:

1.

Remove burners from combustion chamber by raising

burners up from manifold orifi ces and pulling toward

front of boiler. See Figure 17 .

2.

Disconnect vent pipe from draft hood.

3.

Remove top jacket panel.

4.

Remove combination fl ue collector and draft hood from

boiler castings by loosening nuts on hold down bolts

located on each side of collector. See Figure 17 .

5.

Place sheet of heavy paper or similar material over

bottom of base and brush down fl ue passageways. Soot

and scale will collect on paper and is easily removed

with the paper.

6.

With paper still in place in base, clean top of boiler

castings of boiler putty or silicone used to seal between

castings and fl ue collector. Verify chips are not lodged

in fl ue passageways.

When cleaning process is complete, restore boiler

components to their original position. Use IS-808 GE

silicone (available from distributor) to seal around fl ue

collector and boiler castings.

14 - SEQUENCE OF OPERATION

15 - GENERAL INSTRUCTIONS

Blocked Vent

Safety Switch

Rollout Switch

4 Section Boiler

Rollout Switch

2,3,5

Section Boiler

Integral Draft

Hood

Base

Burner

Door

Burners

Orifi ces

Jacket Base

Panel

Manifold

Figure 17 - Blocked Vent Safety Switch, Roll-

out Safety Switch