2 a/d conversion, A/d conversion, Figure 3-2 – ADLINK USB-1210 User Manual

Page 32: Daughter board functional block diagram, Io connector, 40 pin board to board conn x2

22

Operation & Calibration

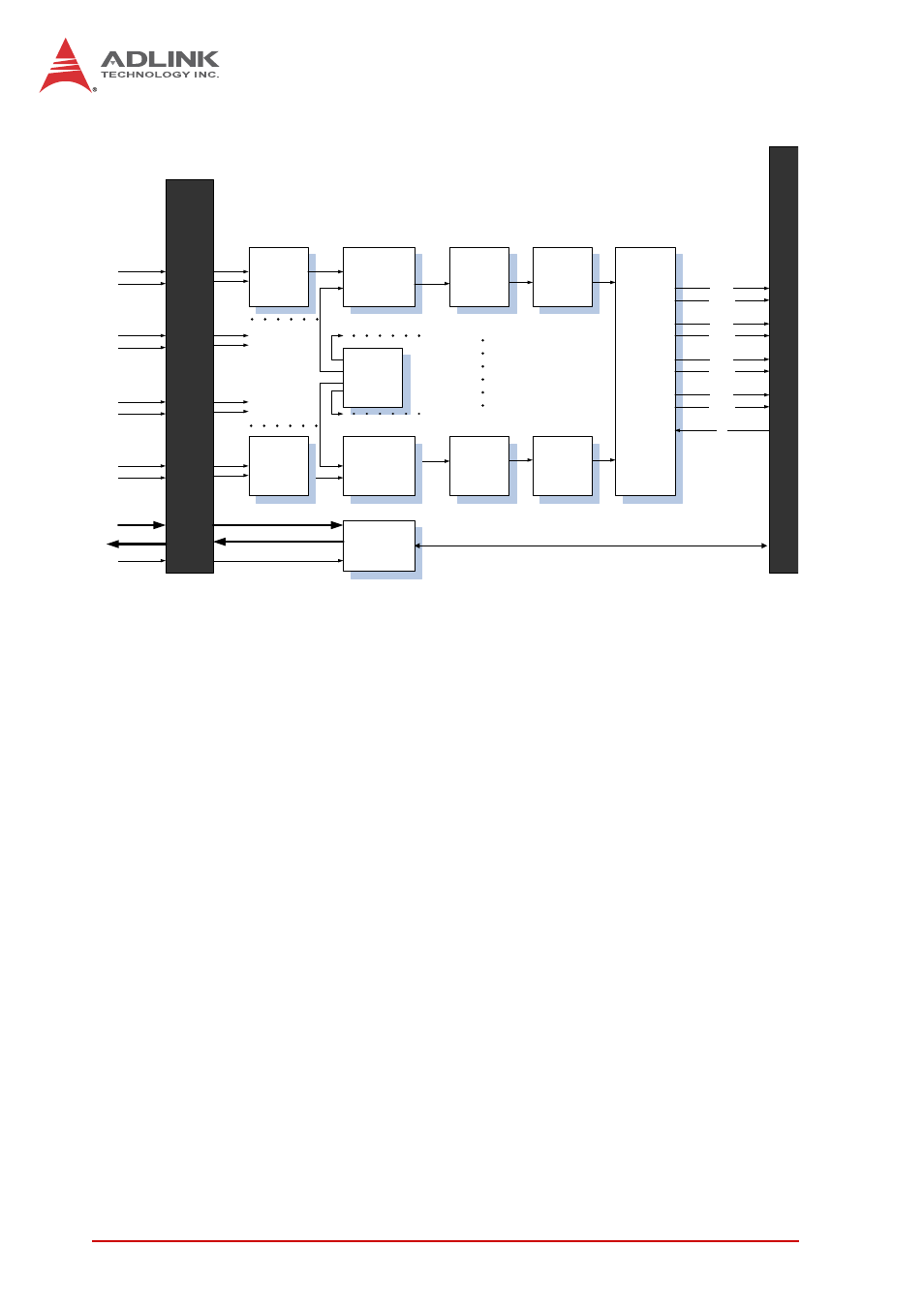

Figure 3-2: Daughter Board Functional Block Diagram

3.1.2

A/D Conversion

When using an A/D converter, the properties of the signal to be

measured must be considered and a channel and connection of

signals to the module selected. Please see Section 1.7: Analog

Input Signal Connection. As well, A/D signal configuration,

including channel, gain, and signal type must be defined and set.

A/D acquisition is initiated by a predefined trigger source. Data

acquisition will commence once a trigger condition is matched.

After A/D conversion, A/D data is buffered in a data FIFO for

transfer into system memory for further processing.

DC path/

Calibration Source

SW

PGA

Signal

Protection

2nd-order

LPF

1st CH

Four channels

ADC

4th CH

Calibration

Mux and

Reference Src

BUSY_CH0

2nd-order

LPF

PGA

IO Connector

AI CH0+

DC path/

Calibration Source

SW

Signal

Protection

AI CH0-

AI CH1+

AI CH1-

AI CH2+

AI CH2-

AI CH3+

AI CH3-

SCK

SDO_CH0

BUSY_CH1

SDO_CH1

BUSY_CH2

SDO_CH2

BUSY_CH3

SDO_CH3

40 Pin Board to Board Conn x2

DI

DO

Trigger

DIO

And

Trigger

DI CH[7..0]

DO CH[3..0]

AI TRIGGER