Owner’s manual, Cleaning and maintenance, Continued – Desa Remington 100271-01 User Manual

Page 15

102891

OWNER’S MANUAL

13

FILE HO

LDER

Top Plate

(left side

of chain)

Groove

Depth

Gauge

(left side

of chain)

Depth

Gauge

(right side

of chain)

Left

Side of

Chain

Right

Side of

Chain

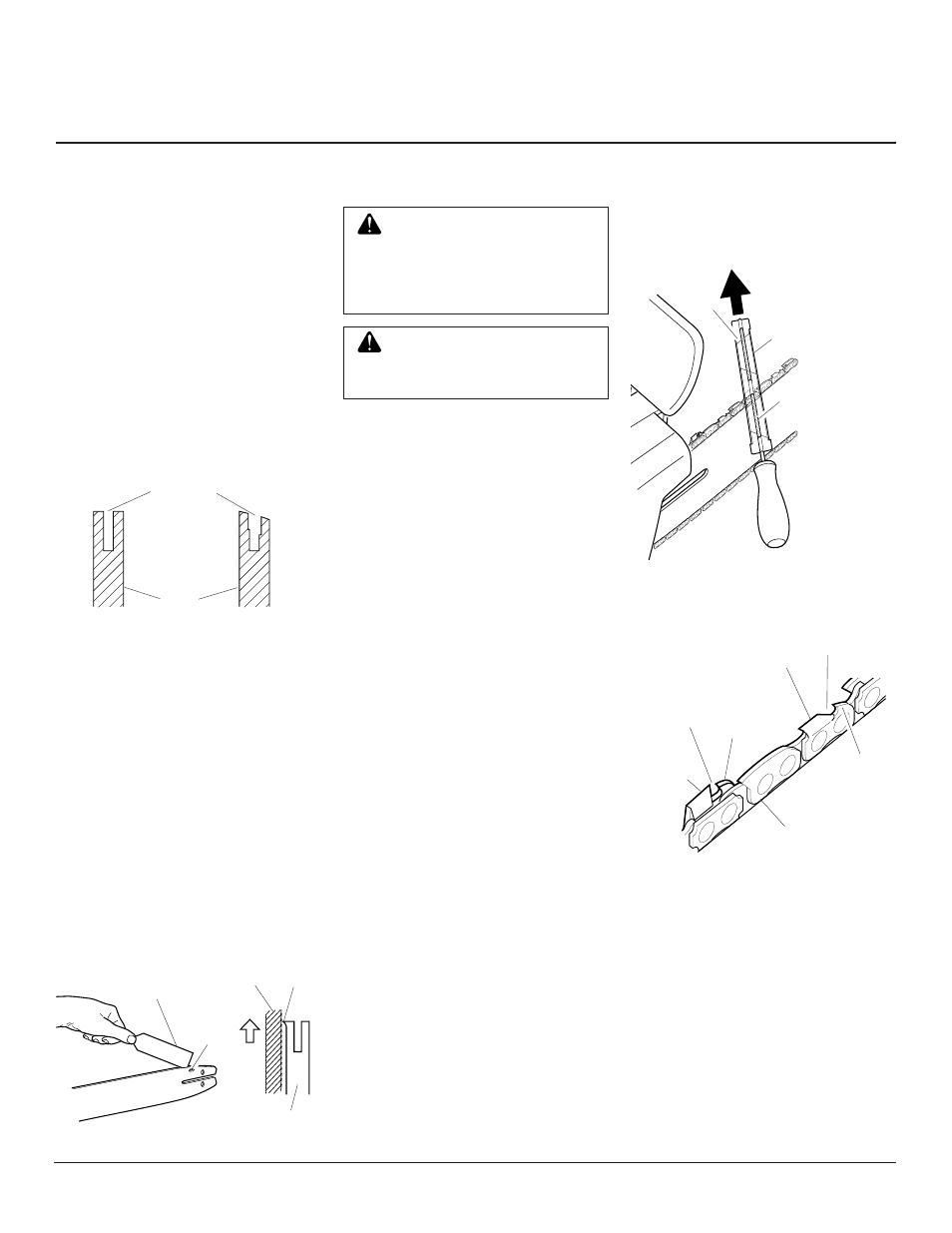

Figure 21 - Chain Part Locations

Top Plate

(right side

of chain)

Groove

Figure 20 - File and File Guide Placement

On Chain

30

°

Guide

Mark

File Guide

4 mm

Round File

Note: This

illustration

shows file guide

placement and

filing direction

for sharpening

cutters on left

side of chain.

Filing

Direction

Keep chain sharp. Your saw will cut faster

and more safely. A dull chain will cause

undue sprocket, guide bar, chain, and motor

wear. If you must force chain into wood and

cutting creates only sawdust with few large

chips, chain is dull.

Items Needed to Sharpen Chain

Purchase these items from your local dealer,

hardware store, or chain saw supplies outlet.

• 4 mm round file

• Depth gauge tool

• File guide

• Vise

• Medium sized flat file

Sharpening Cutters

Use file guide for 30

° filing.

1.

Adjust chain for proper tension (see Saw

Chain Tension Adjustment, page 8).

2.

Clamp guide bar in vise to hold saw

steady.

Note:

Do not clamp chain.

3.

Press four millimeter round file (at-

tached to file guide) into groove be-

tween top plate and depth gauge on

chain. File guide should rest on both

top plate and depth gauge (see Figures

20 and 21).

Note:

File at midpoint of

guide bar.

4.

Hold file guide level. Make sure 30

°

mark on file guide is parallel to center

of guide bar (see Figure 20). This will

insure that you file cutters at 30

° angle.

5.

File from inside towards outside of cut-

ter until sharp. Only file in this one direc-

tion (see Figure 20).

Note:

Two or three

strokes with file should sharpen cutter.

6.

After each cutter if sharpened, move

chain forward to sharpen next cutter.

File all cutters on one side of chain.

7.

Move to other side of chain and repeat

process.

SHARPENING YOUR SAW

CHAIN

WARNING: Unplug chain saw

from power source before servic-

ing. Severe injury or death could

occur from electrical shock or

body contact with moving chain.

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

Figure 19 - Guide Bar Maintenance

Cleaning Groove

With Putty Knife

Oil

Slot

Flat

File

Burr

Guide Bar

Normal Guide Bar Maintenance

1.

Remove guide bar from chain saw.

2.

Remove sawdust from guide bar groove

periodically. Use putty knife or wire.

3.

Clean oil slots after each day of use.

4.

Remove burrs from sides of guide bar.

Use flat file to make side edges square.

Replace guide bar when

• bar is bent or cracked

• inside groove of bar is badly worn

Note:

When replacing guide bar, see Re-

placement Parts, page 14, for proper bar.

Figure 18 - Guide Bar Cross Section

Showing Uneven Bar Wear

Normal

Guide Bar

Guide Bar With

Uneven Wear

Guide

Bar

CLEANING AND

MAINTENANCE

Continued

Guide Bar

Groove

Continued

CARE OF GUIDE BAR

Uneven bar wear causes most guide bar

problems. Incorrect sharpening of chain

cutter and depth gauge settings often cause

this. When bar wears unevenly, it widens

guide bar groove (see Figure 18). This causes

chain clatter and rivet popping. Saw will not

cut straight. Replace guide bar if this occurs.

Inspect guide bar before sharpening chain.

A worn or damaged guide bar is unsafe. A

worn or damaged guide bar will damage

chain. It will also make cutting harder.