Spindle speeds – Delta 17-950L User Manual

Page 17

17

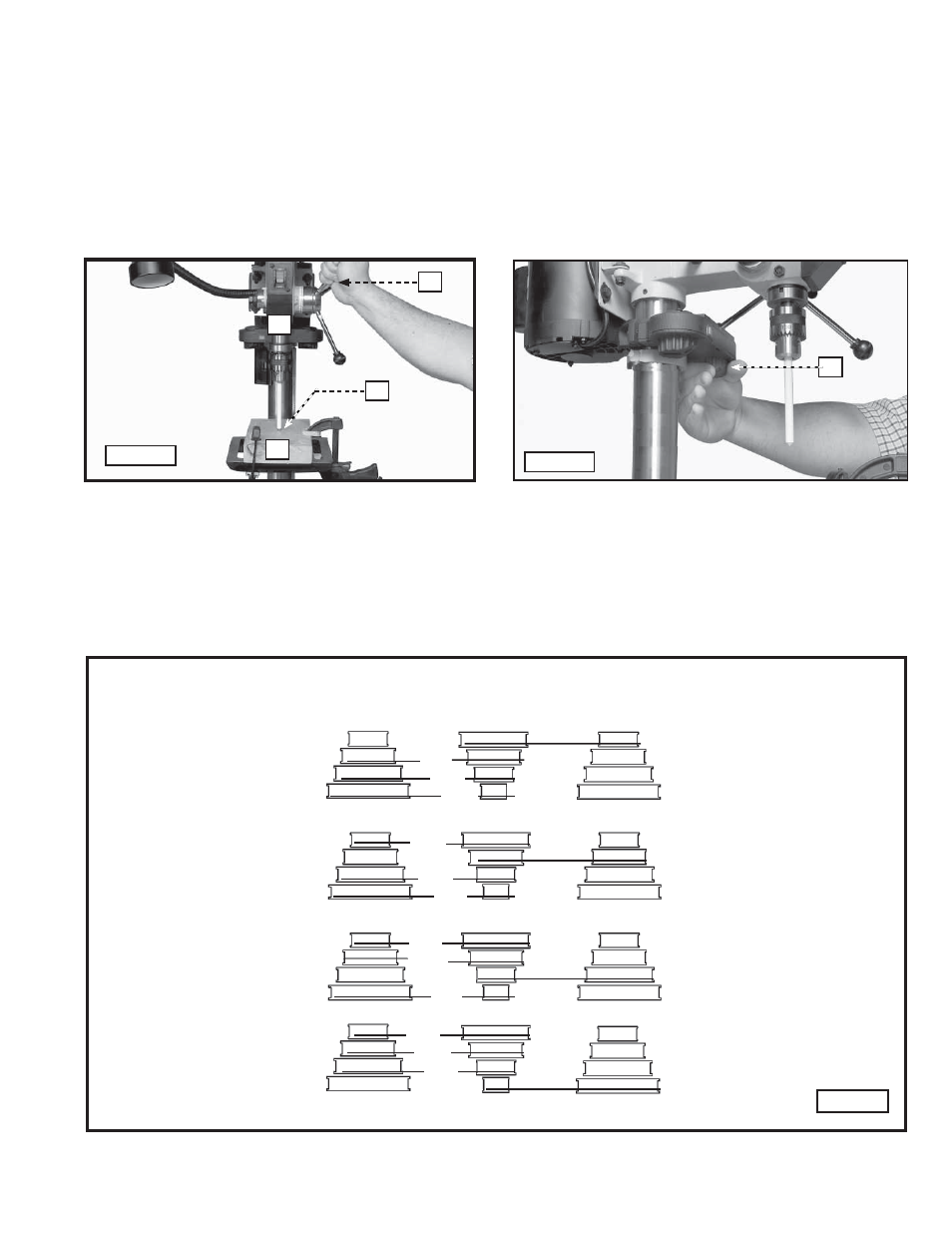

MAKING THE LASERS INTERSECT

1. Place a piece of wood (A) Fig. L4 on the table and clamp it in place.

2. Use the handle (B) to lower the quill (C). Make an indentation in the wood with the alignment pin (D) Fig. L4.

3. Turn on the laser and adjust both beams to intersect at that point by rotating the laser holder (A) Fig. L5.

4. Ensure that the lasers align at different heights. Raise or lower the table, make a new indentation, and turn on the

lasers. If the lasers do not align at different heights, you will need to check the parallel adjustment.

5. Once the lasers are adjusted, tighten the screws on each side of the laser housing, two of which are shown at (F)

Fig. L2.

Fig. L4

A

D

C

Fig. L5

A

B

SPINDLE SPEEDS

Twelve spindle speeds are available on the drill press. Fig. 28A illustrates the belt positions and the corresponding

speeds.

SPINDLE

CENTER

MOTOR

540

360

250

1090

590

410

1820

1280

650

3000

2180

1450

Fig. 28A

- 340-WE-DST (1 page)

- 3584 Series (8 pages)

- 23-725 (16 pages)

- 520-WF (1 page)

- DC-580 20" PLANER 22-451 (24 pages)

- Victorian 3555-LHP (1 page)

- 2171 (1 page)

- 503-WF (1 page)

- 481 Series (2 pages)

- 1837 (2 pages)

- 46-756 (24 pages)

- 13" PORTABLE PLANER 22-590 (52 pages)

- 2520 Series (8 pages)

- 488 Series (8 pages)

- ShopMaster SM300 (51 pages)

- 187 Series (1 page)

- 174 Series (8 pages)

- 100-WF-10 (1 page)

- 2302-LHP (1 page)

- HDS 3000 (1 page)

- TP305 (49 pages)

- 4551 (1 page)

- 502 Series (8 pages)

- 402-WF (1 page)

- 1324 (2 pages)

- 340-WF (1 page)

- 70-200 (17 pages)

- 46-462 (8 pages)

- 117-DST (12 pages)

- 1343-NPS (2 pages)

- 15915 Series (6 pages)

- 50102 Series (4 pages)

- DP350 (17 pages)

- DNS100 (15 pages)

- 403-WF (1 page)

- 11-985 (16 pages)

- 144915 (1 page)

- 2530-LHP (1 page)

- Victorian 2755 Series (5 pages)

- 2785 Series (2 pages)

- 187-WF (1 page)

- 15910 (6 pages)

- 3544-WFMPU (1 page)

- 2400LF (1 page)

- 16968-DST Series (40 pages)