Air evacuation, Drying times and energy consumption, Connection to a ventiiation duct – ASKO 7005 User Manual

Page 7: Specification

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Specification

Height

32 1/4" (820 mm)

Width

23 1/2" (595 mm) +

exhaust hose

connection

Depth

23 1/2" (595 mm),

including controi

panel and program

knob

Depth - Door open

46“ (1170 mm)

Weight

86 lbs. (39 kg)

Speed

52 rpm

Drum materiai

Stainless steel

Outer casing

Galvanised steel

sheet

Instaiiation

Free-standing, buiid-

in or on top of a

washing machine

Power requirement

3150 W

For connection

Doubie-phase,

208-240 V , 3 0 A

Internai fuse

15A

Power requirement

3150 W

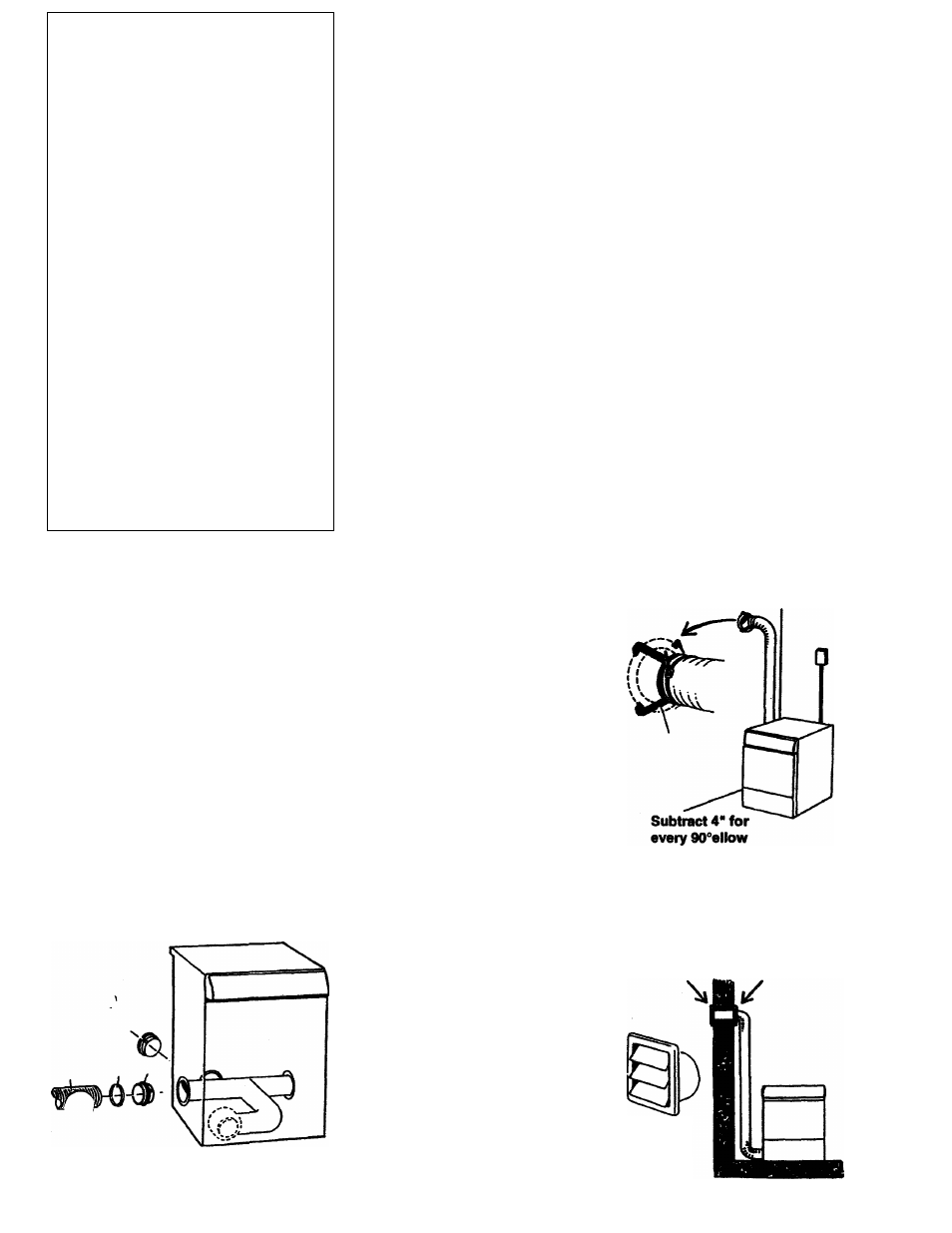

Air evacuation

The air evacuation can be connected at the

rear. When the machine is belvered, one

the rear is open.

T rio tumble dryer is supplied with a stub

pipe, A UL-CSA hose must be supplied by

the consumer or installer.

Fit the air evacuation as foiiows:

• Push the hose onto the stub pipe and

fasten a clamp.

• Insert the stub pipe with the hose into the

hole.

WARNING - To reduce the risk of fire, this

appliarwe MUST BE EXHAUSTED

OUTDOORS or the equivalent.

Drying times and energy

consumption

Drying times and energy

consumption

The table below shows drying times

and energy consumption in

accordance with the following

conditions:

• Program 2 has been used (the

normal "Dry" automatic program).

• Drying temperature Normal

• Fabrics dried are of cotton,

previously spun at 800 r/min.

• The dryer is in a room with a

temperature of 20° C (68° F), and

the exhaust hose supplied with the

machine is in use.

Drying times

many factors, such as the

amount of washing, moisture

content, type of fabric, air

temperature and humidity.

Performance can also be

affected by how the machine

has been installed. Drying

time is also naturally affected

by how dry the washing is to

be when removed from the

machine.

Connection to a

ventiiation duct

Connect the exhaust hose to a ventilation

exhaust fitting or to a discharge through

the wall.

Secure the hose joint to the outlet stub on

the machine.

Run the hose with as few bends as

possible to the point of discharge. If

necessary, it can be extended to a

maximum of 22 feet erf 4" diameter hose.

Make any bends as gentle as possible. A

maximum of four 90° bends may be fitted

in the hose. The more bends and the

longer the hose, the less will be the

amount of air passing through the

machine.

If more than 22 feet of hose is needed,

diameter must be increased to 6* or 8".

If the hose is taken to a wall outlet, a

ventiiation grille should be fitted to prevent

reverse ftow of cold air.

IMPORTANTI

The appliance should not be exhausted

into a chimney, a wall, a ceiling, or a

concealed space of a buildirvg.

The only rigid of flexible metal duct should

be used for exhausting, unless the

appliance has been investigated for use

with nonmetallic duct.

Fit the ventilation

grille to the inside

or outside of the

wall

Ventilation

grille