Bevel angle adjustment, Shoe adjustment for 90° cuts – Black & Decker TRIMCAT 2832 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

blade friction at a minimum, removes sawdust from the cut, results in cool

er, faster sawing and reduces the chance of kickback. A method tor checking

tor correct cutting depth is shown in Figure 5. Lay a piece of the material you

plan to cut along the side of the blade, as shown, and observe how much

tooth projects beyond the material.

NOTE:

When using carbide-tipped blades, make an exception to the above

rule and allow only one-halt of a tooth to project below the material to be cut.

Bevel Angle Adjustment

The full range of the bevel adjustment is from 0° to 50°. The quadrant is grad

uated in increments of 5°. On the front of the saw is a bevel angle adjustment

mechanism (Figure 5) consisting of a calibrated quadrant and a knob. To set

the saw for a bevel cut:

1. TURN OFF TOOL AND REMOVE BAHERY PACK.

2. Loosen (counterclockwise) the quadrant knob and tilt shoe to the desired

angle by aligning the pointer with the desired angle mark. Retighten knob

firmly (clockwise).

NOTE:

The quadrant pointer, located between the quadrant knob and the

quadrant, can be adjusted after loosening its screw. Retighten firmly after

adjustment.

Shoe Adjustment for 90° Cuts

If additional adjustment is needed:

1. TURN OFF TOOL AND REMOVE BATTERY PACK.

2. Adjust the saw to 0° bevel.

3. Retract blade guard. Place the saw on blade side.

4. Loosen bevel adjustment knob. Place a square against the blade and

shoe to adjust the 90° setting.

5. Loosen the hex nut with a wrench or needle nose pliers, and move the

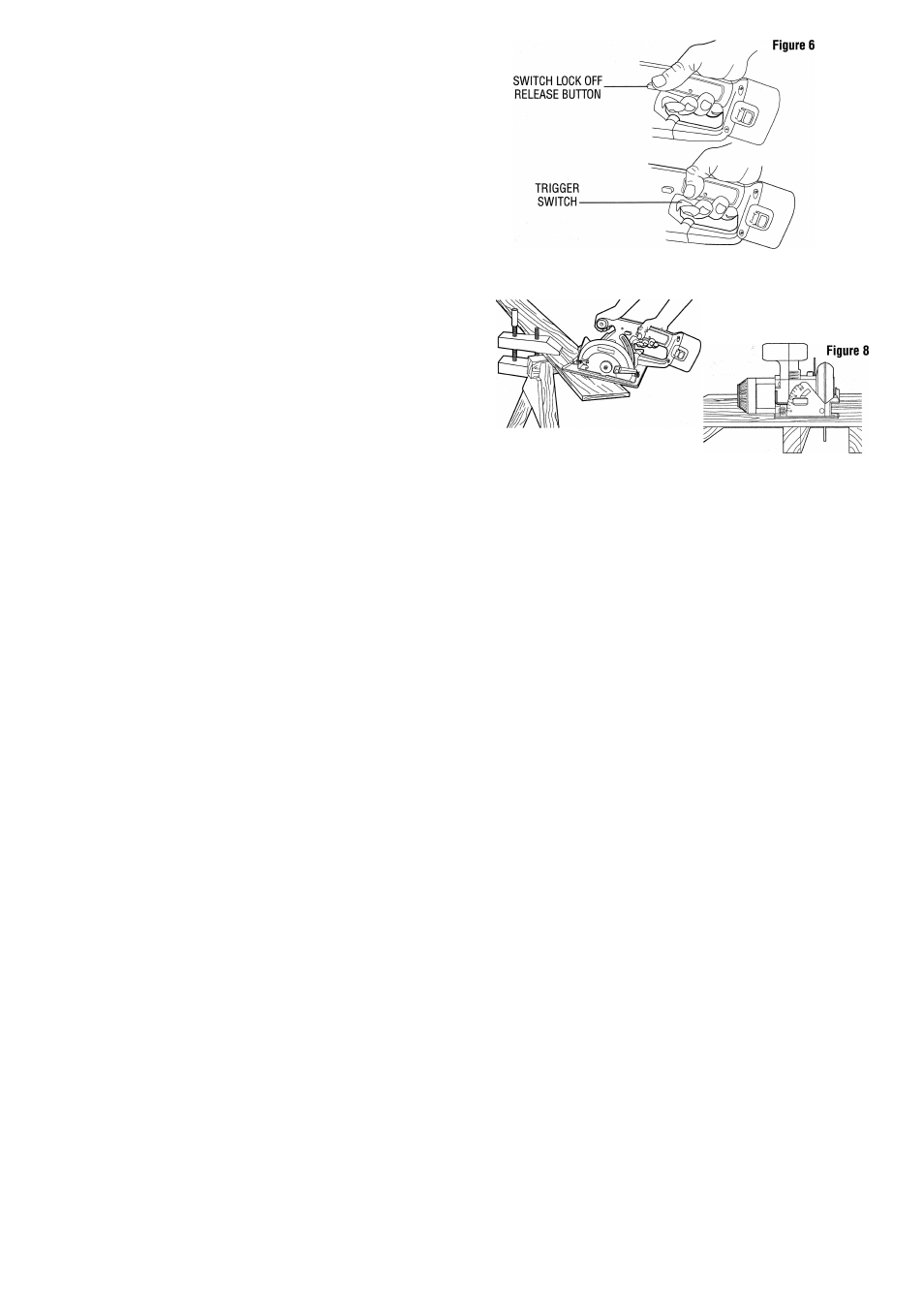

Figure 7

DO support board or

panel NEAR the cut.

SUPPORT