Water manometer, Air shutter adjustment, Temperature rise – Bryant UNIT 379H User Manual

Page 5: Section viii. maintenance, Cleaning the heating unit, Filter

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Water Manometer

When using a water manometer to measure the mani

fold pressure, proceed as follows to adjust the gas in

put:

1. Turn off gas to unit. Connect manometer to 1/8-

inch pressure tap at outlet of gas valve.

2. Turn on gas to unit. With burners fired and both

first and second stage gas valves open, adjust the

pressure regulator to obtain the correct manifold

pressure as shown in Table II. Check with local gas

utility for Btu value and specific gravity of gas in the

area.

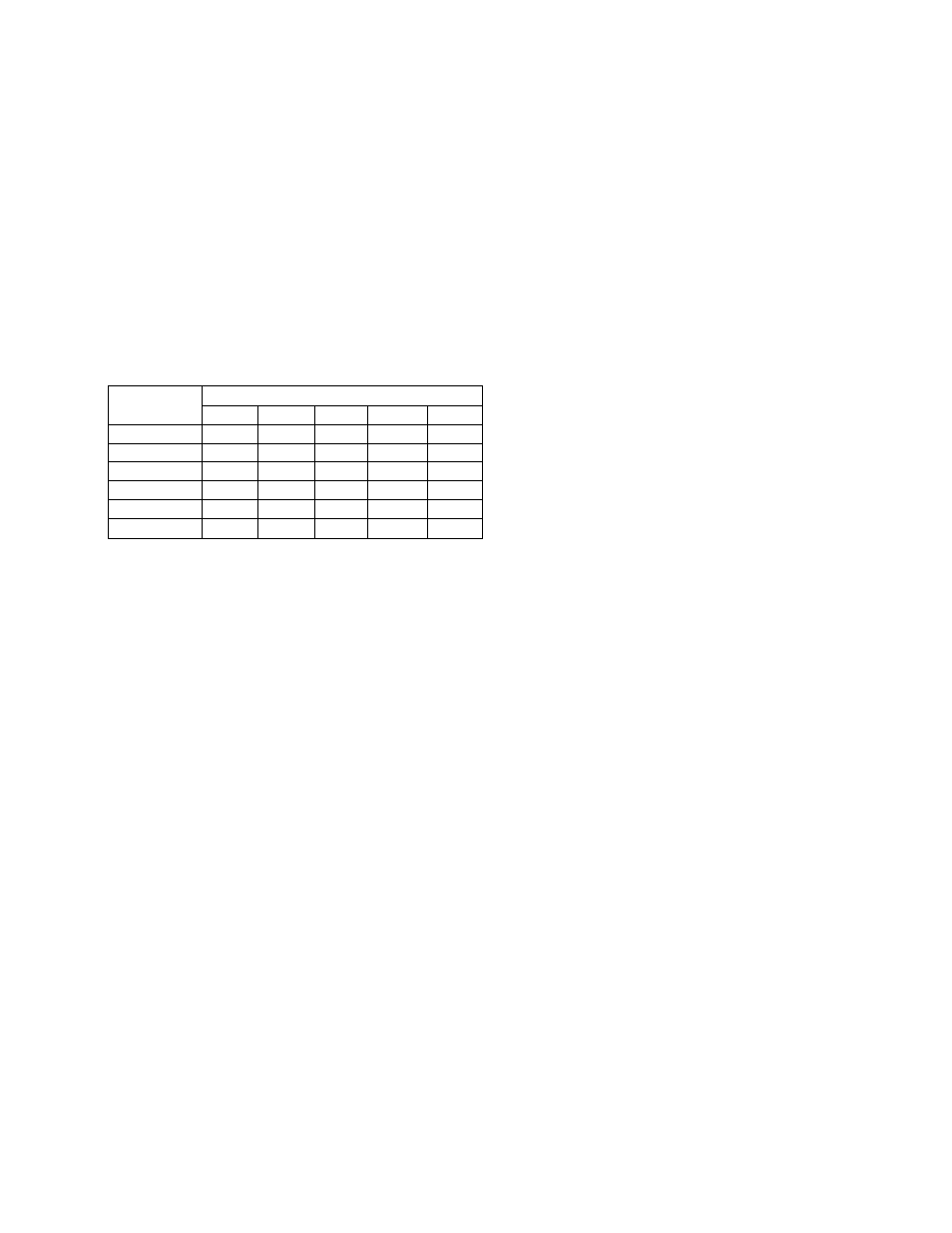

TABLE II

BTU

Specific Gravity

Value

0.59

0.61

0.63

0.65

0.67

900

3.8

3.9

4.0

4.1

4.2'

950

3.3

3.4

3.5

3.6

3.7

1000

3.0

3.1

3.2

3.3

3.4

1025

2.8

2.9

3.0

3.1

3.2

1050

2.7

2.8

2.9

3.0

3.1

1100

2.4

2.5

.L.C

2.7

2.8

Example; Heating value of gas in the area is 1030

Btu; Specific gravity is 0.62.

(a) From Table II the manifold pressure required for

450,000 Btuh is 3.0 inches wc.

(b) Set manifold pressure to 3.0 inches water column

by adjusting gas pressure regulating screw.

If the required manifold pressure exceeds 3.3 inches

w.c. or is less than 2.7 inches w.c., the orifices should

be sized according to unit requirements.

CAUTION: Do not redrill orifices under any circum

stances.

Air Shutter Adjustment

To adjust the primary air to each burner, partially

close the air shutter until there is a slight yellow tip

on the top of the flame, then open the air shutter until

the yellow tip just disappears. This should be done af

ter the burners have been operating at full input for 5

or 10 minutes (approximately).

Temperature Rise

Models 450-379H, 180R-, and 240R-379 are designed

for operation within a temperature rise range of 20 °F

to 75°F against an external static pressure up to 1.0

inch water column.

NOTE: Temperature rise is the difference between

the temperature of the air in the return air duct and

the temperature of the air in the discharge duct near

the heating section.

SECTION VIII. MAINTENANCE

Lubrication: Refer to the rating plate for the blower

motor lubrication requirements.

Cleaning the Heating Unit

1. Be sure that main line disconnect switch is in OFF

p o s i t i o n .

TAG SWITCH WITH SUITABLE WARNING

LABEL.

2. Remove front access panel.

3. Turn off manual gas valve and pilot valve.

4. Disconnect pilot and escapement tubing.

5. Remove burners.

6. Remove flue baffle retainer and the flue baffles.

7. Clean flue passages with suitable brush.

8. Reassemble furnace by reversing above procedure,

making sure all seals are reinstalled properly.

9. Check belt conditions and for proper belt tension

(1/2 inch deflection).

Filter

Filters in Models 240R- and 450-379H are of the

permanent type and should be inspected and cleaned

at regular intervals. Filters used in Model 180R-379H

are of the disposable type and should be inspected

and replaced with filters of the same type and size. In

spections should be made on a regular basis; the time

interval between inspection will depend on the type

of application.

-5-

39379D35