Attaching the hoses, Final assembly, Operation – Bolens 522 User Manual

Page 8: Initial preparation, Service engine with gasoline and oil as

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Reservoir

Tank

/ /

Suction

Hose

FIGURE 9.

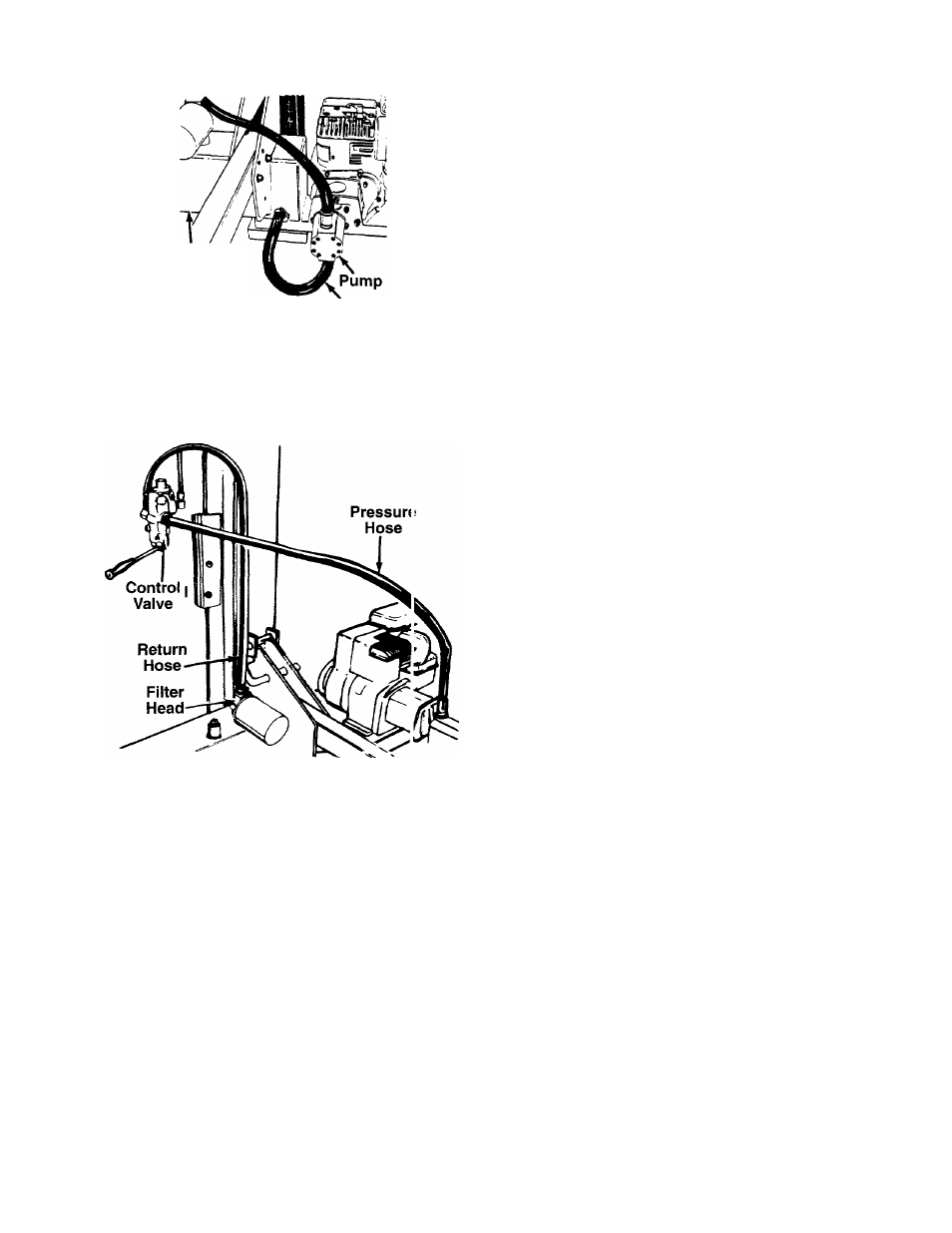

FIGURE 10.

ATTACHING THE HOSES

Suction Hose

1. The suction hose is attached to the reservoir tank,

beneath the engine mounting bracket. See figure

9. Loosen the hose clamp on the free end of the

hose using a screwdriver.

2. Remove the protective cap from the fitting on the

bottom of the pump (some oil may flow from

pump). Attach the end of the suction hose to the

fitting on the bottom of the pump. Place the hose

clamp at the base of the fitting, and tighten

securely.

NOTE: Check all hose ends and remove any plugs.

Discard plugs.

Return Hose

1. The return hose is attached to the top of the con

trol valve. Loosen the hose clamp on the free end

of the hose using a screwdriver. Cut off the secur

ing strap.

2. Remove the protective cap from the fitting on top

of the filter head. Attach the end of the hose to the

fitting on top of the filter head. See figure 10.

Place the hose clamp at the base of the fitting,

and tighten securely.

Pressure Hose

The pressure hose is attached to the top of the valve.

Route the hose as shown in figure 10. Secure the

pressure hose to the bottom of the pump, using two

wrenches.

FINAL ASSEMBLY

1. Pull the locking rod on the beam support/latch

bracket away from the log splitter tongue (refer to

figure 5), and pivot it down. Carefully lower the

wedge, beam and cylinder assembly to the

horizontal position. Secure the beam with the

locking rod.

2. Make certain all nuts, bolts and hose clamps are

tightened securely.

3. Before operating the log splitter, make certain

to follow “Initial Preparation” instructions in

Operation section.

OPERATION

INITIAL PREPARATION

1. Place the log splitter on a dry, firm, leve surface.

Block the wheels.

2. Service engine with gasoline and oil as

instructed in the separate engine manu< I packed

with your log splitter.

3. Lubricate the beam area where splitting wedge

will slide with engine oil (DO NOT USE GREASE).

Make certain to oil both front and back of the

beam face.

4. Fill the reservoir tank as follows.

a. Remove reservoir vent plug. See fgure 11.

Using Dexron II automatic transmission fluid,

or

low

non-foaming hydraulic fluid, fill reser

voir to the top. Replace vent plug seci rely.

NOTE: Total capacity of system is approximately 4

gallons.

b. Disconnect the spark plug wire. Prime the

pump by pulling the recoil starter, to turn

the engine over, approximately 10 times.

Reconnect the spark plug wire.

c. Start engine. Use the control handle to extend

the wedge to the far extended position. Leave

the wedge in this position (do not retract).

d. Refill tank to within 1-1/2" to 2" from the top of

the tank.

e. Now retract the wedge. Extend and retract the

wedge fully 10 to 12 complete cycles to

remove trapped air in the system (system is

“self-bleeding”).